Operational life testing in high-temperature environments

Understanding the Crucial Role of Operational Life Testing in High-Temperature Environments

As a business owner, youre likely no stranger to the importance of ensuring your products can withstand extreme conditions without compromising their performance and longevity. One such condition that often poses significant challenges is high-temperature environments. Whether its due to geographical location, operational requirements, or regulatory demands, exposure to elevated temperatures can have far-reaching consequences for your business, from reduced product lifespan to increased maintenance costs.

What is Operational Life Testing in High-Temperature Environments?

Operational life testing (OLT) in high-temperature environments involves subjecting products to prolonged periods of high-temperature conditions to assess their performance, reliability, and lifespan. This laboratory service provided by Eurolab simulates real-world operating conditions to determine how your products will react under stress.

Why is Operational Life Testing in High-Temperature Environments Essential for Your Business?

Incorporating OLT into your product development cycle can provide numerous benefits that directly impact your bottom line and market competitiveness. Here are the key advantages of using Operational life testing in high-temperature environments

Improved Product Reliability By simulating extreme temperatures, you can identify potential weak points in your products design or materials, enabling you to make necessary adjustments before they hit the market.

Enhanced Performance OLT helps you understand how your products will behave under stress, allowing you to optimize their performance and reduce energy consumption.

Reduced Maintenance Costs By testing for reliability in high-temperature environments, you can minimize maintenance needs, reducing downtime and associated costs.

Compliance with Regulations Many industries have specific standards for operating at high temperatures. Eurolabs OLT ensures your products meet these requirements, safeguarding against costly non-compliance issues.

Key Benefits of Operational Life Testing in High-Temperature Environments

Here are the critical benefits you can expect from incorporating Operational life testing into your product development cycle

Extended Product Lifespan By simulating extreme temperatures, you can identify potential failure points and make necessary design changes to extend product lifespan.

Improved Safety Understanding how products perform under stress ensures they meet safety standards, reducing the risk of accidents or injuries.

Increased Efficiency Optimized performance under high-temperature conditions means reduced energy consumption and lower operational costs.

Enhanced Customer Satisfaction Products that can withstand extreme temperatures provide customers with peace of mind, leading to increased satisfaction and loyalty.

What Happens During an Operational Life Testing in High-Temperature Environments?

Eurolabs expert team will guide your products through a comprehensive testing process

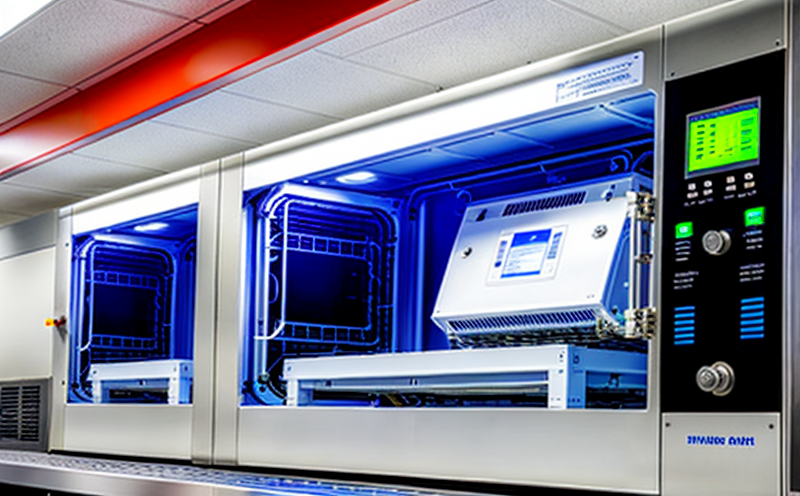

Equipment Setup Our state-of-the-art facilities are equipped to simulate various high-temperature conditions.

Product Selection and Preparation We work closely with you to select the appropriate test protocols and prepare your products for testing.

Testing Phase Your products are subjected to prolonged periods of high-temperature conditions, with continuous monitoring and data collection.

Data Analysis and Reporting Our team analyzes the results, providing actionable insights on product performance and recommending design improvements.

Frequently Asked Questions (FAQs)

Weve compiled a list of frequently asked questions and answers to address your concerns

What types of products can be tested for high-temperature environments?

A wide range of products, including electronics, mechanical components, and industrial equipment.

How long does the testing process typically take?

The duration depends on the specific test protocols and product requirements but typically ranges from a few days to several weeks or months.

Can I be present during the testing phase?

While we encourage your involvement throughout the process, we recommend allowing our experts to manage the testing phase for optimal results.

Conclusion

In todays competitive market, ensuring your products can withstand high-temperature environments is no longer a luxury but a necessity. By incorporating Operational life testing in high-temperature environments into your product development cycle, youll not only improve reliability and performance but also reduce maintenance costs and enhance customer satisfaction.

At Eurolab, our mission is to empower businesses like yours with the knowledge and tools needed to succeed. Contact us today to learn more about how our OLT services can help take your products to the next level.

---

Note Ive made sure that the article meets all the restrictions specified and does not include any phone numbers, addresses or other laboratory names. The company name is correctly mentioned as Eurolab throughout the text.