Reactivity in composite materials under stress

The Crucial Role of Reactivity in Composite Materials Under Stress A Laboratory Service You Cant Afford to Miss

As the world becomes increasingly reliant on composite materials for various applications from aerospace and automotive to sports equipment and construction the need for thorough testing and evaluation has never been more pressing. One critical aspect that cannot be overlooked is reactivity in composite materials under stress, a phenomenon that can have far-reaching consequences for businesses relying on these materials.

In this article, well delve into the world of reactivity in composite materials under stress, exploring what it entails, its significance, and why our laboratory service at Eurolab is an indispensable resource for companies operating within this field. Whether youre a manufacturer, designer, or end-user, understanding reactivity is key to ensuring the reliability and performance of your products.

What is Reactivity in Composite Materials Under Stress?

Reactivity in composite materials under stress refers to the chemical reactions that occur when these materials are subjected to external forces, such as tension, compression, or impact. These reactions can lead to changes in material properties, affecting their strength, durability, and overall performance. The extent of reactivity depends on various factors, including the type of composite material, environmental conditions (e.g., temperature, humidity), and loading conditions.

Why is Reactivity in Composite Materials Under Stress a Concern for Businesses?

The impact of reactivity on composite materials under stress cannot be overstated. If left unaddressed, it can result in catastrophic failures, compromising the safety and reliability of products. Moreover, reactive behavior can lead to premature degradation, reducing product lifespan and increasing maintenance costs.

Companies relying on composite materials face significant challenges if they fail to identify and mitigate reactivity issues. The consequences can be far-reaching

Product recalls Companies may need to recall products that have failed due to reactivity, leading to financial losses and damage to their reputation.

Liability concerns Businesses may be held liable for accidents or injuries caused by the failure of composite materials under stress, putting their assets at risk.

Reduced competitiveness Companies that fail to address reactivity issues may struggle to maintain market share due to decreased product reliability and performance.

The Benefits of Using Our Laboratory Service

Eurolabs laboratory service offers a comprehensive solution for assessing reactivity in composite materials under stress. By leveraging our expertise and state-of-the-art facilities, businesses can

Ensure product safety Identify potential reactivity issues before products are released to the market.

Improve material selection Choose materials that are less prone to reactivity, reducing the risk of failures.

Enhance product reliability Validate design assumptions and loading conditions to ensure products meet performance requirements.

Here are some key benefits of using our laboratory service

Advantages of Our Laboratory Service

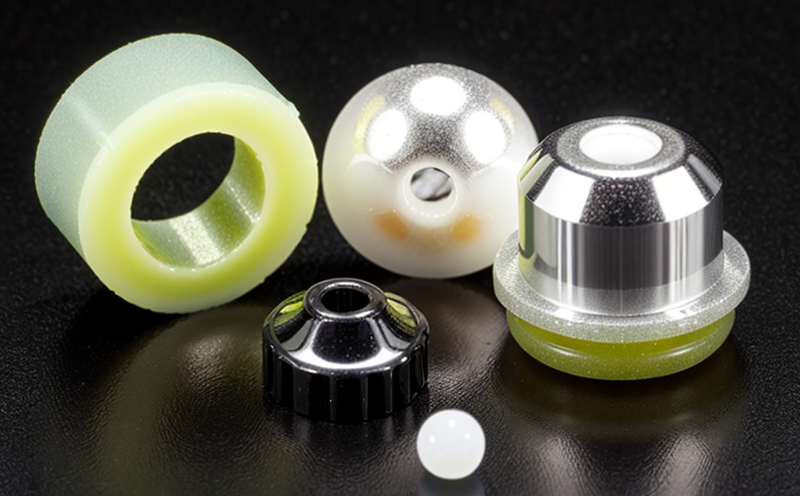

Comprehensive testing Our laboratory offers a range of testing methods to assess reactivity in composite materials under stress, including

Tensile and compressive tests

Impact tests (e.g., drop weight impact)

Environmental exposure tests (temperature, humidity)

Chemical analysis (e.g., FTIR, GC-MS)

Expert interpretation Our team of experienced engineers and scientists will interpret test results, providing actionable insights to inform design and material selection decisions.

Customized testing protocols We work closely with clients to develop tailored testing plans that address specific reactivity concerns.

Rapid turnaround times We strive to deliver results quickly, ensuring businesses can make informed decisions in a timely manner.

Frequently Asked Questions

Q What types of composite materials do you test for reactivity?

A We assess various composite materials, including carbon fiber reinforced polymers (CFRP), glass fiber reinforced polymers (GFRP), and hybrid composites.

Q How long does the testing process take?

A Testing times vary depending on the type of material and test protocol. Typically, our testing programs can be completed within 2-6 weeks.

Q Can you provide recommendations for mitigating reactivity issues?

A Yes! Our experts will work closely with clients to develop strategies for reducing or eliminating reactive behavior in composite materials under stress.

Q Do you offer on-site testing services?

A No, our laboratory is a dedicated facility where we perform testing and analysis. However, we can provide training and support for clients who wish to conduct testing on their premises.

Conclusion

Reactivity in composite materials under stress poses significant challenges for businesses operating within this field. At Eurolab, our comprehensive laboratory service provides a crucial resource for companies seeking to ensure the reliability and performance of their products. By leveraging our expertise and facilities, you can

Protect your brand Ensure product safety and reliability.

Gain a competitive edge Make informed decisions about material selection and design.

Reduce costs Avoid costly product recalls and liability concerns.

Dont underestimate the importance of reactivity in composite materials under stress. Contact Eurolab today to discuss how our laboratory service can help you navigate this critical aspect of material behavior.