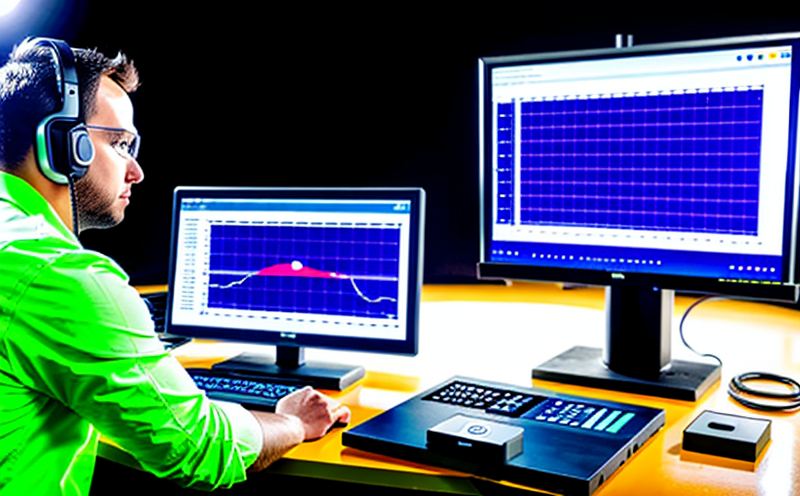

Real-time monitoring during ballistic resistance testing

Unlock the Power of Real-Time Monitoring Revolutionizing Ballistic Resistance Testing

In todays fast-paced world, where innovation and technological advancements are shaping industries at an unprecedented rate, businesses cannot afford to compromise on quality, safety, and performance. One critical aspect that plays a significant role in ensuring the integrity and reliability of materials is ballistic resistance testing. This rigorous process evaluates how materials stand up against high-velocity impacts, simulating real-world threats. However, for this testing to be effective, it requires something more real-time monitoring.

At Eurolab, our cutting-edge laboratory service incorporates real-time monitoring into ballistic resistance testing, providing unparalleled insights and data that empower manufacturers and researchers to make informed decisions about their materials and products. In this comprehensive guide, we will delve into the world of real-time monitoring during ballistic resistance testing, exploring its advantages, benefits, and how it can transform your business.

The Importance of Real-Time Monitoring in Ballistic Resistance Testing

Ballistic resistance testing is a critical evaluation process that simulates various scenarios where materials may be exposed to high-impact threats. This could range from bullets and shrapnel to explosions and other forms of severe impact. Traditional methods of post-testing analysis, while informative, do not provide the immediate feedback that real-time monitoring offers.

Real-time monitoring during ballistic resistance testing involves tracking the performance of a material in real-time as it undergoes the testing process. This is achieved through advanced sensors and data analytics software that provide detailed, minute-by-minute updates on how the material withstands the impact. These insights are crucial for several reasons

- Safety First By understanding exactly how materials perform under various conditions in real-time, manufacturers can ensure their products meet or exceed safety standards, protecting users from harm.

- Quality Control Real-time data allows for immediate adjustments to production lines if any material does not meet expectations. This ensures consistency and quality across all products.

- Innovation Acceleration The detailed insights provided by real-time monitoring can accelerate innovation. By understanding exactly how materials fail or perform under certain conditions, researchers can develop new materials with enhanced properties.

Key Benefits of Real-Time Monitoring in Ballistic Resistance Testing

The advantages of incorporating real-time monitoring into ballistic resistance testing are multifaceted and transformative

- Enhanced Safety Features Products designed to meet specific safety standards benefit from immediate feedback on their performance under simulated threats, ensuring a higher level of protection for end-users.

- Optimized Material Usage Real-time data helps manufacturers optimize material usage by identifying which materials perform best in specific conditions. This reduces waste and saves resources.

- Accelerated Research and Development Immediate insights into material performance accelerate the research and development process, allowing for the creation of new products or improvements to existing ones with enhanced properties.

- Data-Driven Decision Making Real-time monitoring provides a wealth of data that can inform every stage of production, from design to post-production analysis. This data-driven approach ensures that decisions are informed by the most current and accurate information available.

- Competitive Advantage By adopting real-time monitoring in ballistic resistance testing, companies gain a competitive edge through their ability to create safer, higher-quality products more efficiently than competitors who do not have access to this level of detailed analysis.

Common Misconceptions About Real-Time Monitoring

Despite its clear benefits, there are misconceptions about the feasibility and applicability of real-time monitoring in ballistic resistance testing

- Cost Some may believe that real-time monitoring is a costly luxury. However, it can lead to significant cost savings in the long run by reducing material waste, improving production efficiency, and avoiding costly redesigns.

- Complexity Others might think that implementing real-time monitoring is too complex for their business. However, with modern technology making such systems more accessible than ever, this barrier has largely been eliminated.

Real-Time Monitoring A Paradigm Shift in Ballistic Resistance Testing

The integration of real-time monitoring into ballistic resistance testing marks a significant shift towards more informed, data-driven decision-making processes across industries. By adopting this cutting-edge approach, manufacturers and researchers can not only improve the safety and performance of their products but also accelerate innovation while reducing costs.

QA Frequently Asked Questions About Real-Time Monitoring During Ballistic Resistance Testing

Q1 What is real-time monitoring in ballistic resistance testing?

A1 Real-time monitoring involves tracking a materials performance as it undergoes ballistic resistance testing using advanced sensors and data analytics software, providing immediate feedback on how the material withstands impacts.

Q2 Why is real-time monitoring essential for businesses?

A2 It ensures that materials meet or exceed safety standards, optimizes material usage, accelerates research and development, informs data-driven decision-making, and provides a competitive advantage in the market.

Q3 What are the key benefits of using real-time monitoring during ballistic resistance testing?

A3 These include enhanced safety features, optimized material usage, accelerated innovation, data-driven decision making, and a competitive edge over competitors who do not utilize this technology.

Q4 How does real-time monitoring reduce costs for businesses?

A4 By reducing material waste through better production planning based on real-time data and avoiding costly redesigns by getting immediate insights into material performance.

Q5 What are the long-term implications of adopting real-time monitoring in ballistic resistance testing?

A5 It can lead to a significant reduction in costs, improved product quality, accelerated innovation, and a substantial competitive advantage in the market.

Conclusion

In an era where technological advancements are driving industries forward, Eurolabs commitment to incorporating real-time monitoring into ballistic resistance testing sets it apart as a leader in laboratory services. By adopting this cutting-edge approach, businesses can not only ensure their products meet the highest standards of safety and performance but also drive innovation while reducing costs.

Whether youre a manufacturer looking to enhance your product line or a researcher seeking to accelerate breakthroughs in material science, Eurolabs real-time monitoring service for ballistic resistance testing offers a transformative solution. Join the vanguard of companies leveraging technology to create safer, more efficient products and processes. Choose Eurolab for your laboratory needs today.