Residue analysis in medical devices

The Importance of Residue Analysis in Medical Devices Ensuring Patient Safety and Regulatory Compliance

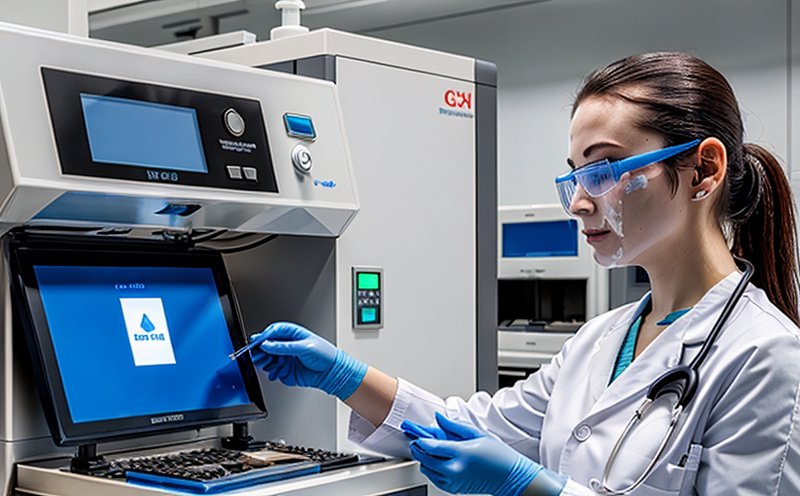

In the rapidly evolving world of medical devices, one critical aspect often overlooked is residue analysis. This laboratory service is crucial for businesses to ensure patient safety, maintain regulatory compliance, and prevent costly recalls. At Eurolab, our team of experts specializes in providing comprehensive residue analysis services that cater to the unique needs of medical device manufacturers.

What is Residue Analysis in Medical Devices?

Residue analysis involves identifying and quantifying residual materials, such as extractables and leachables, on or within medical devices. These substances can originate from various sources, including manufacturing processes, packaging materials, and environmental factors. The primary goal of residue analysis is to determine whether these residues pose a risk to patient safety or device performance.

Why is Residue Analysis Essential for Medical Device Manufacturers?

The consequences of neglecting residue analysis can be severe. Inadequate detection and quantification of residual substances can lead to

Patient harm Exposure to toxic or bioactive compounds can cause adverse reactions, infections, or even death.

Regulatory fines and penalties Failure to comply with regulations, such as ISO 10993-18, can result in significant financial burdens and damage to a companys reputation.

Product recalls If residues are not properly identified and addressed, manufacturers may be forced to recall products, leading to substantial economic losses.

Benefits of Residue Analysis in Medical Devices

Our residue analysis services at Eurolab offer numerous advantages for medical device manufacturers

Comprehensive Risk Assessment Our expert team conducts thorough risk assessments to identify potential hazards associated with residual substances.

Regulatory Compliance We ensure that your products meet or exceed regulatory requirements, minimizing the risk of fines and penalties.

Improved Patient Safety By detecting and mitigating residues, we help protect patients from adverse reactions and complications.

Cost Savings Early detection and remediation of residues can prevent costly recalls and product redesigns.

Enhanced Product Quality Our services enable manufacturers to identify areas for improvement, resulting in higher-quality products.

Key Benefits of Residue Analysis

Here are some key benefits of residue analysis in medical devices

Early Detection Identifies potential hazards before they become major issues

Reduced Recall Risk Helps prevent costly recalls and product redesigns

Regulatory Confidence Ensures compliance with regulations, such as ISO 10993-18

Patient Safety Assurance Protects patients from adverse reactions and complications

How to Choose the Right Residue Analysis Service Provider

When selecting a residue analysis service provider, consider the following factors

Expertise Look for experienced professionals with in-depth knowledge of medical device regulations and standards.

Accreditation Ensure that the laboratory is accredited by recognized third-party organizations, such as NELAC or ILAC.

State-of-the-Art Equipment Opt for a provider with access to advanced analytical instruments and technologies.

Frequently Asked Questions (FAQs)

Q What types of medical devices require residue analysis?

A Our services cater to a wide range of medical devices, including implants, surgical instruments, diagnostic equipment, and more.

Q How long does the residue analysis process typically take?

A The duration varies depending on the complexity of the project; however, our team works efficiently to ensure timely results.

Q What are the most common residual substances found in medical devices?

A Our experts have identified common contaminants, such as silicone oils, lubricants, and adhesives.

Q Can I conduct residue analysis in-house or do I need an external laboratory?

A While some companies may choose to conduct internal analyses, partnering with a specialized laboratory like Eurolab ensures objective results and minimizes the risk of errors.

Conclusion

Residue analysis is an essential component of medical device development, ensuring patient safety and regulatory compliance. At Eurolab, our team of experts provides comprehensive residue analysis services that cater to the unique needs of medical device manufacturers. By choosing us as your trusted partner, you can

Ensure Patient Safety Protect patients from adverse reactions and complications

Maintain Regulatory Compliance Meet or exceed regulations, minimizing fines and penalties

Enhance Product Quality Identify areas for improvement, resulting in higher-quality products

Trust Eurolab to deliver accurate, timely, and reliable residue analysis results. Contact us today to learn more about our services and how we can support your medical device manufacturing needs.