Sensor functionality testing for robotic systems used in packaging

The Crucial Role of Sensor Functionality Testing for Robotic Systems in Packaging Unlocking Efficiency and Accuracy

In todays fast-paced manufacturing landscape, businesses are constantly seeking innovative ways to optimize their packaging processes while ensuring product quality and consistency. One critical aspect that often gets overlooked is the testing of sensor functionality in robotic systems used for packaging applications. At Eurolab, our team of experts understands the significance of this service and offers a specialized laboratory service designed to identify potential issues and improve overall performance.

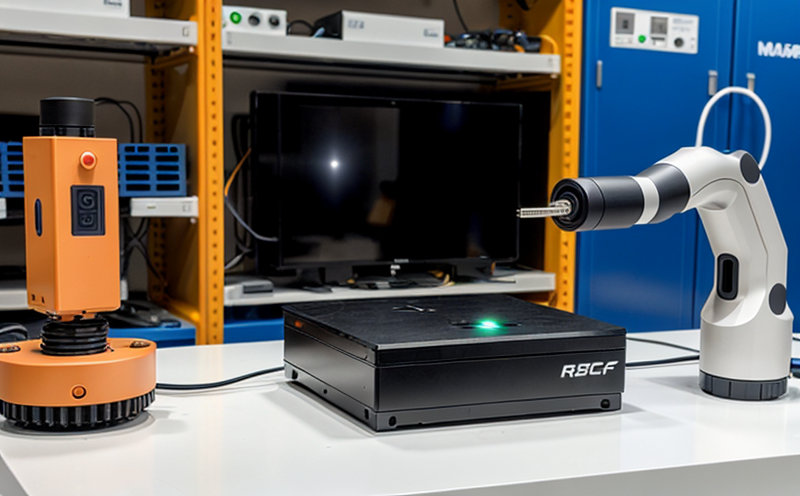

Sensor functionality testing is an essential component of any robotic systems maintenance routine. This process involves evaluating the sensors ability to detect, track, and respond to various stimuli within the packaging environment. Accurate sensor function is critical for precise object detection, accurate picking and placement, and efficient handling of products. When sensors fail or operate below par, it can lead to costly errors, decreased productivity, and compromised product quality.

The Advantages of Sensor Functionality Testing for Robotic Systems in Packaging

Our comprehensive laboratory service provides a range of benefits that can significantly impact the performance and efficiency of your packaging operations

Improved Productivity By identifying and addressing sensor-related issues promptly, you can minimize downtime and optimize production times. This enables you to meet growing demand while maintaining quality standards.

Reduced Costs Preventing errors and minimizing repairs through early detection can lead to substantial cost savings over time. Our testing services help you avoid the financial burdens associated with equipment failure or rework due to subpar sensor function.

Enhanced Quality Control Sensor functionality testing ensures that your robotic system is accurately detecting products, reducing the risk of damage during handling and packaging. This results in higher-quality finished goods that meet customer expectations.

Increased Efficiency Our laboratory service helps optimize sensor configuration and calibration, streamlining interactions between robotic components and enhancing overall performance.

Improved Safety By ensuring accurate sensor function, you can minimize the risk of accidents or injuries associated with malfunctioning equipment.

Data-Driven Decision Making Our comprehensive testing reports provide valuable insights into your packaging operations efficiency, enabling data-driven decisions to optimize processes further.

Key Benefits in Detail

Our Sensor Functionality Testing service offers a range of benefits that cater to specific business needs

Early Detection and Prevention of Errors Regular sensor function tests help identify potential issues before they cause disruptions or damage products.

Comprehensive Analysis and Recommendations Our expert team provides detailed reports, outlining recommended calibration adjustments, configuration improvements, and other corrective actions to enhance performance.

Minimized Downtime Quick turnaround times for our testing services ensure you can get back to production quickly, minimizing lost revenue due to equipment downtime.

Customized Solutions We tailor our laboratory service to meet your specific business needs, taking into account the unique requirements of your robotic system and packaging processes.

Frequently Asked Questions

At Eurolab, we understand that you may have questions about our Sensor Functionality Testing services. Here are some answers to common queries

What types of sensors do you test?

We evaluate a wide range of sensors commonly used in robotic systems for packaging applications, including cameras, lidar, ultrasonic sensors, and more.

How long does the testing process take?

Our laboratory service offers fast turnaround times to minimize downtime. The exact duration depends on the complexity of your robotic system and the number of tests required.

What kind of data will I receive from the testing report?

Our comprehensive reports provide detailed analysis, including sensor performance metrics, recommended adjustments for calibration and configuration, and suggestions for process improvements.

Can I request customization for my specific business needs?

Yes! Our team works closely with you to understand your unique requirements and tailor our services accordingly.

How often should I schedule sensor functionality testing for my robotic system?

Regular maintenance is key. We recommend scheduling tests at regular intervals (e.g., every 3-6 months) or after significant changes to your packaging processes or equipment.

Conclusion

Sensor functionality testing for robotic systems used in packaging is a vital component of any robust quality control program. By investing in our laboratory service, you can unlock improved productivity, reduced costs, and enhanced product quality. At Eurolab, were committed to helping businesses like yours optimize their operations and stay ahead in the competitive manufacturing landscape.

Stay Ahead with Sensor Functionality Testing

Dont let subpar sensor function hold your business back. Contact us today to learn more about our comprehensive laboratory service designed to help you achieve maximum efficiency, accuracy, and product quality.