Shear testing with varying adhesive thickness

Unlocking the Secrets of Adhesive Performance Shear Testing with Varying Adhesive Thickness

As a business owner, you understand the importance of ensuring that your products and materials meet the highest standards of quality and performance. In todays competitive market, even the smallest defect or imperfection can have significant consequences on your brand reputation and bottom line. Thats why Eurolab offers an essential laboratory service Shear testing with varying adhesive thickness.

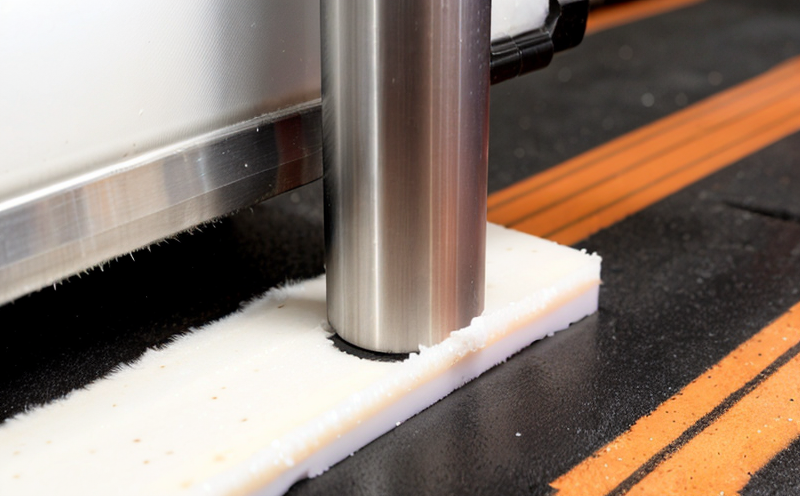

Shear testing with varying adhesive thickness is a non-destructive method used to evaluate the mechanical properties of adhesives under shear stress, a type of force that causes deformation by sliding along a plane parallel to the surface of contact. This test simulates real-world conditions where adhesives are subjected to stresses such as vibrations, thermal expansion, and compression.

What is Shear Testing with Varying Adhesive Thickness?

Shear testing involves applying a compressive load perpendicular to the adhesive joint while measuring the resulting shear stress. The variation in adhesive thickness is critical because it affects the mechanical properties of the adhesive, including its strength, stiffness, and toughness. By analyzing the behavior of adhesives under different thicknesses, manufacturers can identify areas for improvement and optimize their adhesive formulations.

Why Shear Testing with Varying Adhesive Thickness Matters

Here are just a few compelling reasons why this laboratory service is essential for businesses

Ensures Adhesive Performance With Eurolabs Shear testing with varying adhesive thickness, you can ensure that your adhesives meet the required standards of performance and reliability. Our tests simulate real-world conditions to give you confidence in your products ability to withstand stress and strain.

Cost Savings Inadequate adhesive performance can result in costly repairs, replacement, or even product recalls. By identifying potential issues early on through Shear testing, you can save money by optimizing your adhesive formulations and reducing the risk of product failure.

Compliance with Industry Standards Many industries require specific standards for adhesive performance. Eurolabs Shear testing with varying adhesive thickness ensures that our clients meet these standards, reducing the risk of non-compliance and associated costs.

Innovation and RD Our laboratory services support innovation and research and development (RD) by providing valuable insights into the behavior of adhesives under various conditions. This information can be used to develop new adhesive formulations or improve existing ones.

Competitive Advantage By demonstrating a commitment to quality and performance, your business can establish itself as a leader in its industry, setting it apart from competitors who may not prioritize adhesive testing.

Key Benefits of Shear Testing with Varying Adhesive Thickness

Here are the benefits of our laboratory service summarized

Precise Results Our experienced technicians use advanced equipment to provide accurate and reliable results.

Comprehensive Analysis We offer a detailed report on your adhesives performance, including recommendations for improvement.

Customizable Testing We can tailor our testing protocols to meet specific industry standards or customer requirements.

QA Shear Testing with Varying Adhesive Thickness

Were often asked about Shear testing and its applications. Here are some frequently asked questions and answers

Q What types of industries benefit from Shear testing?

A Many industries, including construction, automotive, aerospace, and electronics, rely on adhesives to secure components and materials.

Q How does Shear testing with varying adhesive thickness differ from other types of testing?

A Our unique approach simulates real-world conditions by varying the adhesive thickness, providing a more accurate representation of how your products will perform in actual use.

Q Can I customize the test parameters to suit my specific needs?

A Yes! Eurolab offers flexible and adaptable testing protocols that can be tailored to meet your industry standards or requirements.

Q What kind of sample preparation is required for Shear testing with varying adhesive thickness?

A We require a small sample of the adhesive material, which should be prepared according to our specific guidelines to ensure accurate results.

Conclusion

Shear testing with varying adhesive thickness is an essential laboratory service that helps businesses like yours optimize their adhesive formulations and improve product performance. By understanding how adhesives behave under different conditions, you can reduce costs, increase efficiency, and establish a competitive advantage in the market.

Eurolab is committed to providing the highest level of quality and expertise in our testing services. Our experienced technicians and state-of-the-art equipment ensure accurate results that meet or exceed industry standards. Whether youre looking to improve existing adhesives or develop new ones, we invite you to partner with us for Shear testing with varying adhesive thickness.

At Eurolab, we believe in the importance of collaboration and open communication. Well work closely with your team to understand your specific needs and provide expert guidance every step of the way.

Dont let inadequate adhesive performance hold back your business. Choose Eurolabs laboratory services for Shear testing with varying adhesive thickness and unlock the full potential of your products today.