Short circuit testing for batteries used in medical devices

Ensuring Battery Safety in Medical Devices The Importance of Short Circuit Testing

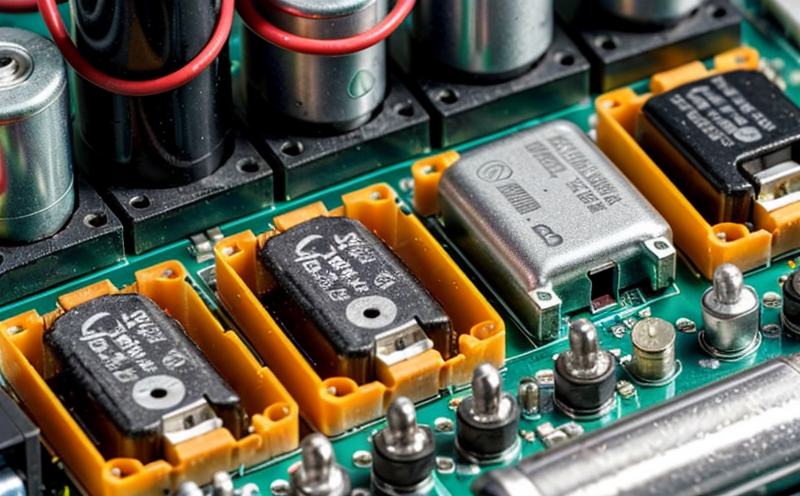

In the world of medical devices, battery safety is a top priority. With lives on the line, manufacturers must ensure that every component, including batteries, meets the highest standards of quality and reliability. One critical laboratory service that plays a vital role in this process is short circuit testing for batteries used in medical devices. As a leading provider of this service, Eurolab understands the importance of battery safety and is dedicated to helping businesses like yours ensure compliance with regulatory requirements.

What is Short Circuit Testing?

Short circuit testing involves subjecting batteries to controlled electrical discharges to simulate real-world usage scenarios. This process allows manufacturers to assess the integrity of their batteries and identify potential safety risks before they reach the market. During short circuit testing, a battery is intentionally short-circuited by applying an electrical current that simulates a fault condition. The resulting data provides valuable insights into the batterys performance under extreme conditions.

Why is Short Circuit Testing Essential for Businesses?

Short circuit testing is crucial for businesses involved in medical device manufacturing because it ensures compliance with regulatory requirements and mitigates potential risks associated with battery failure. In fact, failure to comply with safety standards can result in costly recalls, damage to a companys reputation, and even harm to patients.

Here are some key benefits of using short circuit testing for batteries used in medical devices

Compliance with Regulatory Requirements Short circuit testing helps businesses ensure compliance with regulations such as ISO 9001, ISO 13485, and IEC 60601- This ensures that their products meet international safety standards.

Risk Mitigation By identifying potential battery safety risks early on, manufacturers can take corrective action to prevent costly recalls or product failures.

Improved Product Reliability Short circuit testing helps manufacturers develop more reliable products by providing valuable insights into the performance of their batteries under extreme conditions.

Enhanced Brand Reputation Companies that prioritize battery safety and comply with regulatory requirements are more likely to establish a strong reputation in the industry.

Reduced Liability By demonstrating compliance with safety standards, businesses can reduce their liability in case of product-related injuries or malfunctions.

Advantages of Eurolabs Short Circuit Testing Services

At Eurolab, we offer comprehensive short circuit testing services tailored to meet the unique needs of medical device manufacturers. Our expertise and state-of-the-art equipment ensure that your batteries are thoroughly tested for safety and reliability. Here are some advantages of choosing Eurolab

Accurate Results Our experienced technicians and advanced equipment provide accurate results that help you make informed decisions about your product.

Rapid Turnaround Times We understand the importance of timely testing and delivery. Our streamlined process ensures rapid turnaround times without compromising on quality.

Cost-Effective Solutions Eurolab offers competitive pricing for our short circuit testing services, making it an affordable option for businesses looking to ensure compliance with regulatory requirements.

Expert Support Our team is dedicated to providing exceptional support throughout the testing process. Were committed to helping you achieve your business goals and ensuring that your products meet international safety standards.

Frequently Asked Questions

Here are some frequently asked questions about short circuit testing

Q What types of batteries can be tested for short circuits?

A Eurolab offers short circuit testing services for a wide range of battery types, including lithium-ion, nickel-cadmium, and lead-acid batteries.

Q How long does the testing process typically take?

A The duration of the testing process depends on various factors, such as the type and size of the battery. Our experienced technicians work efficiently to ensure rapid turnaround times without compromising on quality.

Q What kind of equipment is used for short circuit testing?

A Eurolab employs advanced equipment specifically designed for short circuit testing, including high-voltage generators and sophisticated data acquisition systems.

Q Can I customize the testing protocol to meet my specific requirements?

A Yes. Our team works closely with clients to develop customized testing protocols that meet their unique needs and compliance requirements.

Conclusion

In conclusion, short circuit testing is an essential laboratory service for medical device manufacturers seeking to ensure battery safety and comply with regulatory requirements. At Eurolab, were committed to helping businesses like yours achieve these goals through our comprehensive short circuit testing services. By prioritizing battery safety, you can mitigate potential risks associated with product failure, protect your reputation, and ensure compliance with international safety standards.

Dont compromise on safety choose Eurolab for your short circuit testing needs and enjoy the peace of mind that comes with knowing your products meet the highest standards of quality and reliability.