Understanding Shrinkage Rate Variation Unlocking the Secrets to Accurate Material Analysis

In the realm of materials science and manufacturing, understanding the properties of materials is crucial for producing high-quality products that meet customer demands. One critical parameter that manufacturers often overlook is shrinkage rate variation, which can significantly impact product dimensions, weight, and overall performance. Shrinkage rate variation refers to the degree of change in a materials volume or size during processing, such as molding, casting, or forming.

At Eurolab, we recognize the importance of accurate materials analysis and offer a laboratory service specifically designed to measure shrinkage rate variation a critical parameter that can make all the difference between success and failure. In this article, well delve into the world of shrinkage rate variation, exploring its significance, benefits, and the advantages of using our expert laboratory services.

What is Shrinkage Rate Variation?

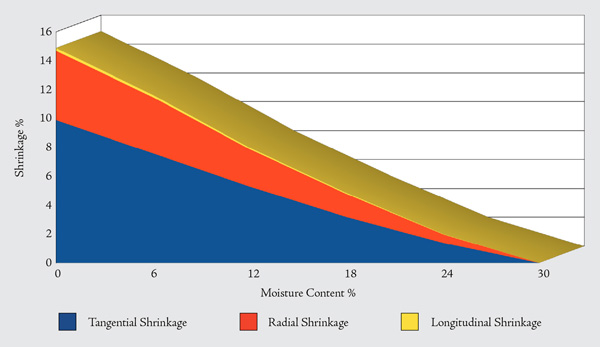

Shrinkage rate variation occurs when materials undergo changes in volume or size due to various factors such as thermal expansion, chemical reactions, or mechanical stress. This phenomenon can lead to dimensional instability, affecting the final products performance, appearance, and overall quality. In industries like plastics, metals, ceramics, and composites, shrinkage rate variation is a critical factor that must be carefully controlled.

Why is Shrinkage Rate Variation Essential for Businesses?

Manufacturers who fail to account for shrinkage rate variation risk producing products with inconsistent dimensions, weights, or performances. This can lead to

Rejected batches due to non-conformity

Increased production costs and waste

Loss of customer trust and loyalty

Strained relationships with suppliers and partners

On the other hand, understanding and controlling shrinkage rate variation enables businesses to

Achieve precise product dimensions and weights

Enhance product performance and durability

Reduce production costs and minimize waste

Build strong relationships with customers and partners based on trust and reliability

The Advantages of Using Shrinkage Rate Variation

Our laboratory service at Eurolab offers a range of benefits that can revolutionize your business. Here are just some of the key advantages

Improved Product Quality By accurately measuring shrinkage rate variation, you can ensure that your products meet customer demands and expectations.

Increased Efficiency Our expert technicians will analyze your materials and provide detailed reports on their shrinkage rates, enabling you to optimize production processes and minimize waste.

Reduced Costs By controlling shrinkage rate variation, you can reduce production costs associated with rejected batches, rework, and material waste.

Enhanced Customer Satisfaction With precise product dimensions and weights, youll be able to deliver high-quality products that meet customer requirements, fostering strong relationships and loyalty.

Competitive Advantage By leveraging our expert laboratory services, youll gain a competitive edge in your industry, differentiating yourself from competitors who fail to account for shrinkage rate variation.

How Does Shrinkage Rate Variation Affect Different Materials?

Shrinkage rate variation can impact various materials in distinct ways. Heres a breakdown of the effects on some common materials

Plastics Thermoplastics exhibit significant shrinkage rates, especially during processing. Accurate measurement is essential to prevent dimensional instability and ensure product quality.

Metals Metals like steel, aluminum, and copper can undergo thermal expansion or contraction, affecting their dimensions and performance.

Ceramics Ceramic materials often exhibit significant shrinkage rates due to chemical reactions or sintering processes.

Composites Composite materials made from various fibers and resins can display complex shrinkage behavior, requiring precise analysis.

QA Section

We understand that you may have questions about our laboratory service. Here are some frequently asked questions (FAQs) to help address your concerns

Q What types of materials can be analyzed for shrinkage rate variation?

A Our expert technicians at Eurolab can analyze a wide range of materials, including plastics, metals, ceramics, composites, and more.

Q How do you measure shrinkage rate variation?

A We employ state-of-the-art equipment and techniques to accurately measure shrinkage rates, including thermal analysis, mechanical testing, and optical microscopy.

Q Can I trust the results of your laboratory service?

A Absolutely! Our technicians are highly trained and experienced in materials science, ensuring accurate and reliable results that you can rely on.

Q How long does it take to receive results from your laboratory service?

A We strive to provide rapid turnaround times, typically within 24-48 hours. However, this may vary depending on the complexity of the analysis and the volume of samples.

Conclusion

Shrinkage rate variation is a critical parameter that can significantly impact product quality, efficiency, and customer satisfaction. By partnering with Eurolabs expert laboratory service, youll be able to accurately measure shrinkage rates, optimize production processes, and gain a competitive edge in your industry. Dont let shrinkage rate variation hold your business back contact us today to learn more about our comprehensive range of services.

Get Accurate Results, Gain a Competitive Advantage

Choose Eurolab for all your laboratory needs. Our state-of-the-art facilities, expert technicians, and commitment to excellence ensure that you receive accurate results that meet the highest industry standards. By leveraging our expertise in shrinkage rate variation analysis, youll be able to unlock new levels of product quality, efficiency, and customer satisfaction.

What Are You Waiting For?

Dont let shrinkage rate variation compromise your businesss success. Reach out to us today to learn more about our laboratory service and discover how we can help you achieve precision, reliability, and a competitive edge in the market.