Simulating extreme weather conditions to test how materials react to rapid changes in climate

Simulating Extreme Weather Conditions The Key to Unlocking Climate Resilient Materials

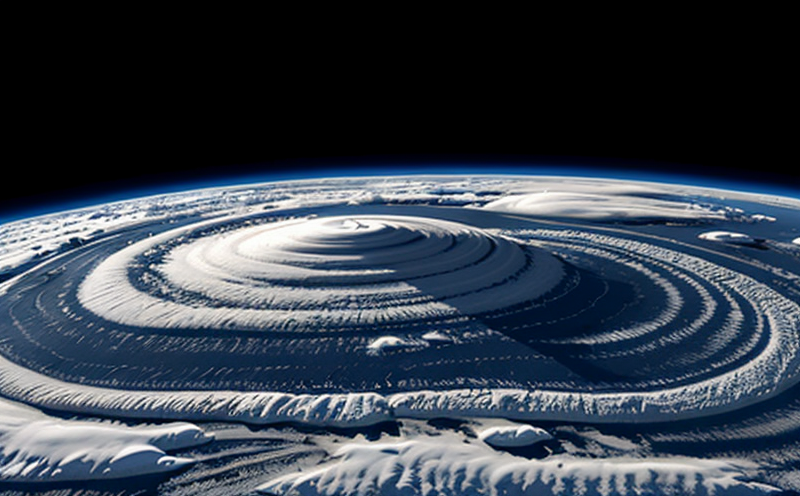

As the world grapples with the challenges of climate change, businesses are faced with an unprecedented need to adapt and innovate. One of the most pressing concerns is ensuring that materials used in construction, manufacturing, and other industries can withstand extreme weather conditions. This is where Simulating Extreme Weather Conditions comes in a laboratory service provided by Eurolab that allows businesses to test how materials react to rapid changes in climate.

What is Simulating Extreme Weather Conditions?

Simulating Extreme Weather Conditions is a cutting-edge technology used to mimic the effects of natural disasters such as hurricanes, floods, and wildfires on materials. By recreating these extreme conditions in a controlled laboratory setting, Eurolab enables businesses to assess the durability and performance of their products under various climate scenarios. This critical testing helps companies identify areas for improvement, reducing the risk of damage, failure, or even catastrophic consequences.

Why is Simulating Extreme Weather Conditions Essential for Businesses?

In todays fast-paced business landscape, staying ahead of the curve requires more than just innovation it demands resilience. Climate change has become a harsh reality, with extreme weather events becoming increasingly frequent and intense. The economic implications are staggering a study by Aon found that global natural disasters resulted in losses exceeding 360 billion in 2020 alone.

By using Eurolabs Simulating Extreme Weather Conditions service, businesses can

Reduce the risk of product failure Identify vulnerabilities and optimize materials to withstand extreme weather conditions.

Save on costs Minimize losses due to material degradation or damage caused by climate-related events.

Enhance brand reputation Demonstrate a commitment to quality and safety, reassuring customers and stakeholders about the reliability of products.

Stay competitive Differentiate your business by investing in cutting-edge technology and demonstrating a proactive approach to climate resilience.

Key Benefits of Simulating Extreme Weather Conditions with Eurolab

Accurate and reliable results Our state-of-the-art facilities ensure precise control over simulated conditions, providing unbiased and dependable data.

Customized testing solutions We adapt our services to meet your specific needs, offering tailored packages for diverse materials and industries.

Rapid turnaround times Get answers quickly with our accelerated testing protocols, minimizing downtime and maximizing productivity.

Expert analysis and reporting Our team of scientists and engineers provide detailed reports and recommendations, empowering you to make informed decisions.

Comprehensive QA Section

Q What types of extreme weather conditions can be simulated?

A We can recreate a wide range of scenarios, including high winds (hurricanes, tornadoes), intense rainfall (flooding), temperature fluctuations (wildfires, heatwaves), and more.

Q Which materials can be tested using Simulating Extreme Weather Conditions?

A Our services cater to various industries and products, such as construction materials (concrete, steel, glass), textiles, plastics, composites, and more.

Q How long does a typical testing project take?

A The duration of our tests varies depending on the complexity of the scenario and the number of samples being tested. Our team will work with you to establish realistic timelines and deliver results efficiently.

Q Can I see the testing process in action?

A Absolutely! We welcome clients to observe our testing procedures, providing a unique opportunity to witness the science behind Simulating Extreme Weather Conditions firsthand.

Why Choose Eurolab for Simulating Extreme Weather Conditions?

At Eurolab, we pride ourselves on our commitment to delivering exceptional results and unparalleled service. Our team of experts has extensive experience in materials science, climatology, and laboratory testing. By partnering with us, you can

Trust the accuracy Leverage the latest technology and expertise to ensure reliable data.

Count on flexibility Adapt our services to meet your evolving needs and deadlines.

Benefit from cost savings Reduce costs associated with material degradation or damage caused by climate-related events.

Dont wait until its too late. Invest in Simulating Extreme Weather Conditions today and unlock the secrets of climate resilient materials. Contact Eurolab to learn more about our comprehensive services and take the first step towards a safer, more sustainable future for your business.

-

Testing the ability of materials to withstand prolonged exposure to environmental elements

-

Simulating long-term exposure to UV light, rain, wind, and temperature fluctuations

-

Evaluating how building materials such as paints, coatings, and sealants hold up under harsh weather

-

Testing for color fading, material cracking, or degradation caused by environmental exposure

-

Ensuring that materials maintain their structural integrity and appearance over time

-

Verifying the durability of construction materials in areas prone to extreme weather patterns

-

Ensuring that exterior materials, including roofing and cladding, remain stable under exposure to the sun

-

Testing the ability of materials to resist the effects of saltwater and humidity in coastal regions

-

Verifying that materials used for outdoor applications are resistant to UV degradation and weathering

-

Simulating the effects of freeze-thaw cycles on construction materials and coatings

-

Evaluating the impact of pollutants in the air on materials used in urban environments

-

Testing how materials respond to repeated exposure to high temperatures and cold snaps

-

Verifying that materials used in construction do not lose their mechanical strength over time

-

Testing the impact of ozone exposure on rubber, plastics, and other vulnerable materials

-

Ensuring that weathered materials retain their original properties and do not compromise building safety

-

Simulating rain, snow, and high winds to determine how materials respond to these forces

-

Testing for the resistance of materials to discoloration or surface damage after extended weather exposure

-

Ensuring that materials used in building envelopes continue to perform in harsh weather without failure

-

Evaluating the protection provided by weather-resistant coatings in long-term outdoor environments

-

Testing for resistance to ice formation and the potential for materials to crack or deform

-

Ensuring that materials are capable of withstanding the test of time in outdoor, high-traffic environments