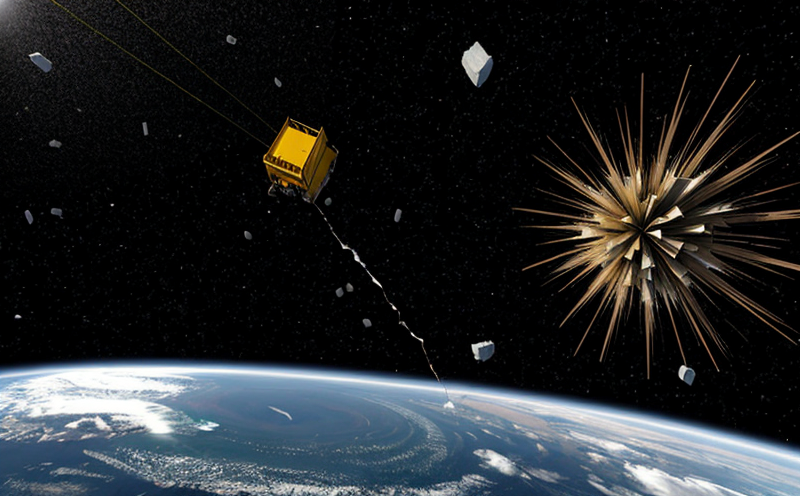

Simulating high-impact scenarios, such as falling debris, collisions, or drops, to assess material resilience

Title Unlocking Material Resilience Simulating High-Impact Scenarios for Unparalleled Reliability and Safety

Introduction

In todays fast-paced business landscape, companies across various industries are under immense pressure to innovate, reduce costs, and ensure the reliability of their products and materials. As a result, assessing material resilience has become an indispensable step in product development, manufacturing, and even daily operations. Simulating high-impact scenarios, such as falling debris, collisions, or drops, is a cutting-edge laboratory service provided by Eurolab that empowers businesses to evaluate the robustness of their materials like never before.

What is Simulating High-Impact Scenarios?

Eurolabs advanced simulation technology allows for the recreation of real-world scenarios in a controlled environment. Our expert technicians subject test samples to intense stress, carefully replicating the forces and energies experienced by materials in practical situations. By mimicking high-impact events such as falls from height, collisions with other objects, or drops onto different surfaces, we provide an unparalleled level of insight into material resilience.

Why is Simulating High-Impact Scenarios Essential for Businesses?

The importance of simulating high-impact scenarios cannot be overstated. In todays highly competitive market, companies are constantly seeking ways to improve product quality, reduce waste, and minimize costs associated with damage or failure. By leveraging Eurolabs simulation capabilities

Enhance Product Reliability Companies can ensure their products meet the highest standards of durability and resilience, reducing the likelihood of costly recalls or warranty claims.

Reduce Material Waste By identifying areas where materials may fail under stress, businesses can optimize production processes and minimize waste associated with defects or damage.

Improve Safety Records Simulating high-impact scenarios allows companies to proactively identify potential safety hazards and implement corrective measures to protect employees, customers, and the environment.

Cut Production Costs By understanding material limitations and vulnerabilities, manufacturers can design products that are more robust and less prone to failure, reducing replacement costs and increasing overall efficiency.

Benefits of Using Eurolabs Simulation Services

Eurolab offers an unparalleled level of expertise and cutting-edge technology to simulate high-impact scenarios. The benefits of choosing our services include

Accurate Results Our advanced equipment and expert technicians ensure the accuracy and reliability of simulation results, providing actionable insights for informed decision-making.

Comprehensive Testing From falling debris to collisions and drops, Eurolabs testing capabilities cover a wide range of high-impact scenarios to evaluate material resilience in various conditions.

Customized Solutions Our team works closely with clients to tailor simulation programs that meet specific project requirements, ensuring the most effective use of resources.

Expert Consultation Upon completion of simulations, our experts provide detailed analysis and recommendations for improving product design or reducing production costs.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested using Eurolabs simulation services?

A Our team has extensive experience with a wide range of materials, including metals, polymers, ceramics, glass, and composite materials.

Q How long does the simulation process typically take?

A The duration of simulations varies depending on project complexity, but our experts can usually provide detailed results within 1-3 weeks from test initiation.

Q Can I witness the simulation process firsthand?

A Yes, we encourage clients to observe the testing process, providing an opportunity for direct engagement and QA with our expert technicians.

Q Will Eurolab provide recommendations or suggestions based on the simulation results?

A Absolutely! Our team of experts will analyze test data, identify areas for improvement, and offer tailored advice to enhance product resilience and safety.

Conclusion

In a world where material reliability is paramount, simulating high-impact scenarios offers an unparalleled level of insight into product performance. By partnering with Eurolab, companies can unlock new levels of efficiency, reduce costs associated with damage or failure, and create safer products for their customers. Dont let your business fall victim to material vulnerabilities trust the experts at Eurolab to help you simulate high-impact scenarios today!

-

Testing the ability of materials to withstand sudden forces or impacts without breaking or deforming

-

Ensuring that materials used in construction do not fail when subjected to impact forces during normal operation

-

Evaluating the durability of construction materials under impact from external forces, such as heavy equipment or machinery

-

Testing materials used for protective barriers, glass, and windows to ensure they can resist impact without shattering

-

Simulating the impact of objects falling or colliding with materials used in roadways, pavements, and buildings

-

Verifying the resistance of construction materials to impact damage caused by natural disasters, such as earthquakes or storms

-

Testing the impact resistance of coatings and sealants to ensure their longevity under harsh conditions

-

Ensuring that materials used for structural components, such as beams and columns, maintain their integrity under impact

-

Simulating the effect of blunt force impact on building materials to assess their ability to absorb shock

-

Testing for cracks, dents, or other damage that may occur when materials are subjected to high-impact forces

-

Ensuring that construction materials used for safety barriers, railings, or fences can withstand impacts without failure

-

Verifying the impact resistance of materials used in automotive and aerospace applications to ensure safety

-

Simulating high-energy impacts to test the durability of materials used in public infrastructure projects

-

Testing for the ability of materials to withstand the impact of moving objects, such as vehicles or machinery

-

Ensuring that materials used for cladding, facades, and roofing can resist damage from hail, falling objects, or debris

-

Verifying that impact-resistant coatings and films can prevent surface damage or failure under high-stress conditions

-

Testing the ability of materials to recover from impact without losing their functionality or strength

-

Ensuring that materials in high-traffic areas do not degrade or crack due to frequent impact exposure

-

Simulating the effect of dropping or crashing objects on sensitive materials used in storage or packaging

-

Evaluating how materials perform under sudden changes in pressure or impact during extreme weather events

-

Testing for shock absorption properties in materials used in sensitive equipment or structures