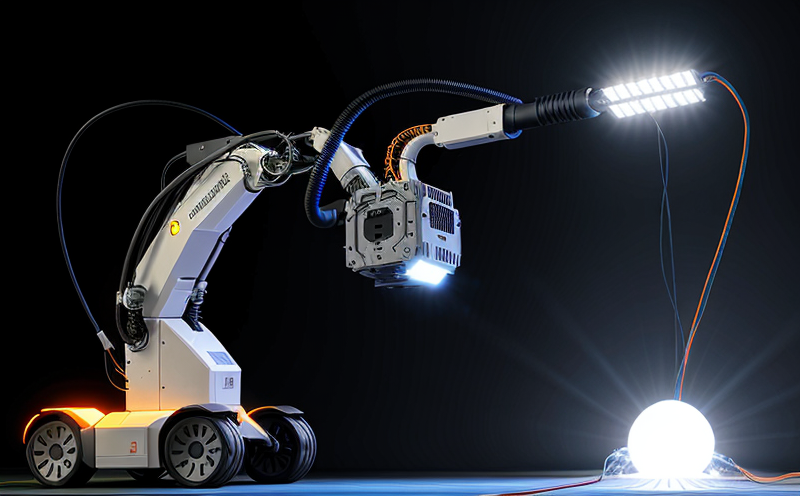

Simulating power fluctuations and their effects on robotic systems

The Power of Simulation Ensuring Robotic Systems Thrive in Dynamic Environments

In todays rapidly evolving industrial landscape, businesses are under pressure to innovate and adapt quickly to changing market demands. One key area where companies can gain a competitive edge is by ensuring the reliability and performance of their robotic systems. However, as these systems become increasingly complex, theyre also becoming more vulnerable to power fluctuations sudden changes in voltage or frequency that can cause equipment malfunction, data loss, or even catastrophic failure.

This is where Simulating Power Fluctuations and Their Effects on Robotic Systems comes into play. Offered by Eurolab, a leading laboratory service provider, this specialized testing capability enables manufacturers to simulate real-world power disturbances in a controlled environment, ensuring their robotic systems can withstand the inevitable ebbs and flows of industrial power grids.

What is Simulating Power Fluctuations and Their Effects on Robotic Systems?

Simulating power fluctuations involves subjecting robotic systems to artificially created voltage or frequency variations that mimic those experienced in real-world environments. This testing process allows manufacturers to evaluate their equipments resilience under stress conditions, identifying potential vulnerabilities and areas for improvement.

Why is Simulating Power Fluctuations and Their Effects on Robotic Systems Essential for Businesses?

In the face of growing competition and increased scrutiny from regulatory bodies, manufacturers cant afford to ignore the risks associated with power fluctuations. By simulating these disturbances in a laboratory setting, companies can

Mitigate equipment damage Reduce downtime and costly repairs by identifying potential vulnerabilities before they cause system failure.

Ensure data integrity Prevent data loss and corruption resulting from power outages or surges.

Improve reliability Enhance the overall performance and dependability of robotic systems, leading to increased productivity and efficiency.

Advantages of Using Simulating Power Fluctuations and Their Effects on Robotic Systems

By leveraging Eurolabs expert services in simulating power fluctuations, businesses can enjoy numerous benefits, including

Cost savings Identify and address potential issues before they cause system failure, reducing costly repairs and downtime.

Increased efficiency Optimize equipment performance by fine-tuning systems to withstand real-world power disturbances.

Improved product quality Enhance the overall reliability of robotic systems, leading to increased customer satisfaction and loyalty.

Reduced risk Minimize exposure to regulatory penalties and reputational damage associated with power-related failures.

Key Benefits of Simulating Power Fluctuations and Their Effects on Robotic Systems

Compliance with regulations Ensure adherence to industry standards and regulations, such as those related to electromagnetic compatibility (EMC) and power quality.

Reduced maintenance costs Minimize the need for costly repairs by identifying potential issues before they cause system failure.

Increased equipment lifespan Prolong the useful life of robotic systems by subjecting them to simulated power disturbances that mimic real-world conditions.

Improved supply chain reliability Enhance supplier relationships and ensure reliable delivery schedules by ensuring robotic systems can withstand power fluctuations.

QA Section

Q What types of robotic systems can be tested using Simulating Power Fluctuations and Their Effects on Robotic Systems?

A Our laboratory services support a wide range of robotic systems, including industrial robots, autonomous vehicles, and medical devices.

Q How do you simulate power fluctuations in the laboratory setting?

A We employ advanced testing equipment and software to create artificial voltage or frequency variations that closely mimic real-world power disturbances.

Q Can Simulating Power Fluctuations and Their Effects on Robotic Systems be integrated with existing quality control processes?

A Yes, our services can be easily incorporated into existing workflows to ensure seamless integration and minimal disruption.

Q What are the typical turnaround times for testing and analysis?

A Our experienced team works efficiently to deliver results within a short timeframe, allowing businesses to quickly address any issues identified during testing.

Conclusion

In todays fast-paced industrial environment, companies cant afford to overlook the risks associated with power fluctuations. By leveraging Eurolabs expert services in simulating these disturbances, manufacturers can ensure their robotic systems are reliable, efficient, and equipped to thrive in dynamic environments.

Dont let power fluctuations compromise your business operations or product quality. Contact Eurolab today to discover how Simulating Power Fluctuations and Their Effects on Robotic Systems can safeguard your investment and drive long-term success.

About Eurolab

Eurolab is a leading laboratory service provider dedicated to helping businesses optimize their products, processes, and equipment. Our team of experts offers a wide range of testing services, including simulating power fluctuations, to support the development and deployment of reliable and efficient robotic systems.