Simulating prolonged exposure to heat and flame to test material integrity over time

The Ultimate Test of Material Integrity Simulating Prolonged Exposure to Heat and Flame

As a business owner, you understand the importance of ensuring the quality and reliability of your products. With increasingly stringent regulations and customer expectations, its more crucial than ever to validate the performance of materials under various conditions. One such critical aspect is material integrity when exposed to heat and flame over an extended period.

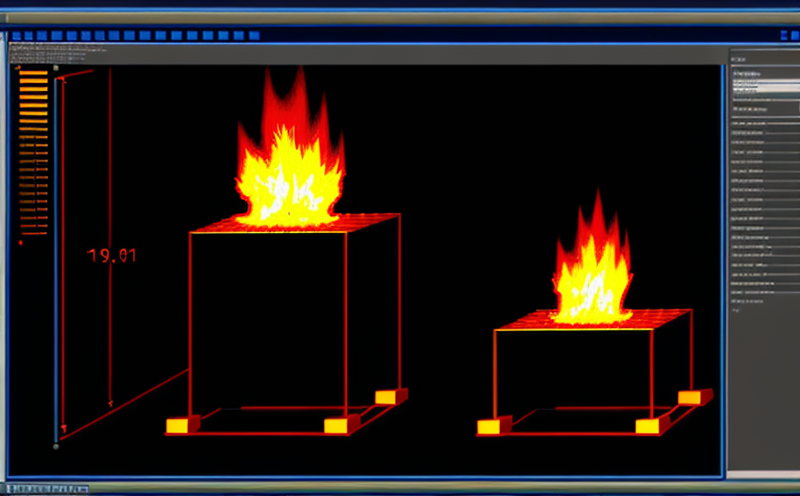

At Eurolab, we offer a cutting-edge laboratory service that simulates prolonged exposure to heat and flame to test material integrity over time. This specialized testing procedure allows you to assess how your products will behave in real-world scenarios, providing invaluable insights for product development, quality control, and regulatory compliance.

The Importance of Simulating Prolonged Exposure to Heat and Flame

Materials exposed to high temperatures or flames can undergo significant changes, affecting their structure, properties, and performance. Prolonged exposure can lead to

Degradation of material strength

Changes in chemical composition

Loss of thermal insulation

Unpredictable behavior under stress

These effects can compromise product safety, functionality, and lifespan. By simulating prolonged exposure to heat and flame, you can

Identify potential weaknesses in your products

Develop strategies for improvement

Comply with regulatory requirements

Enhance customer satisfaction

Advantages of Using Simulating Prolonged Exposure to Heat and Flame at Eurolab

Our state-of-the-art laboratory facility is equipped with the latest technology to simulate a wide range of thermal and flame exposure scenarios. The benefits of using our service include

Predictive Maintenance Our testing allows you to anticipate potential issues, reducing downtime and costs associated with product failure.

Enhanced Safety By understanding how your materials behave under stress, you can design safer products that minimize the risk of accidents or injuries.

Improved Performance We help you identify areas for improvement, enabling you to optimize material properties and enhance overall product performance.

Compliance with Regulations Our testing ensures that your products meet or exceed industry standards and regulatory requirements.

Key Benefits of Simulating Prolonged Exposure to Heat and Flame at Eurolab

Accurate Results Our expert technicians use advanced instruments to measure material properties under simulated conditions, providing precise and reliable results.

Customized Testing We work closely with you to design a testing program tailored to your specific needs and product requirements.

Cost-Effective By identifying potential issues early on, our service helps you avoid costly redesigns or rework.

Time-Saving Our efficient testing procedures minimize the time required for material evaluation, ensuring that you can get back to production quickly.

Frequently Asked Questions

Q What types of materials can be tested using this method?

A We can test a wide range of materials, including plastics, metals, ceramics, and composites.

Q How do you simulate prolonged exposure to heat and flame?

A Our laboratory is equipped with advanced instruments that mimic real-world thermal and flame exposure scenarios, allowing for precise control over temperature, duration, and intensity.

Q Can I watch the testing process in real-time?

A Yes, we offer live observation facilities, enabling you to witness the testing procedure firsthand.

Q How long does the testing process take?

A The duration of our tests varies depending on the specific requirements, but most tests can be completed within a few weeks.

Q What kind of reports and data do I receive after the test?

A Our expert technicians provide comprehensive reports detailing material properties, test conditions, and results. We also offer additional analysis services to help you interpret the data.

Conclusion

Simulating prolonged exposure to heat and flame is an essential step in validating material integrity over time. At Eurolab, we understand the importance of this testing procedure and are committed to providing high-quality services that meet your specific needs.

By partnering with us, you can

Enhance product safety and performance

Comply with regulatory requirements

Reduce costs associated with product failure

Improve customer satisfaction

Dont compromise on material integrity. Contact Eurolab today to schedule a customized testing program for your products.