Simulating temperature cycles in climate chambers to test the reliability of seals and gaskets

Simulating Temperature Cycles in Climate Chambers Unveiling the Reliability of Seals and Gaskets

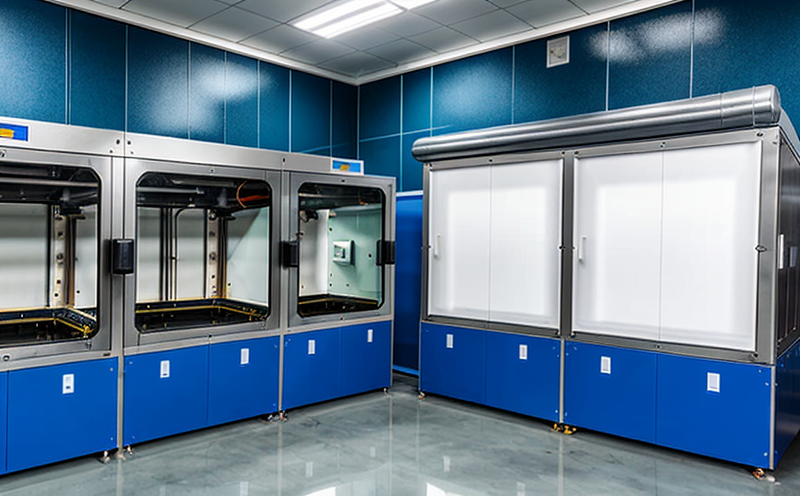

As industries continue to push the boundaries of innovation, ensuring the reliability and durability of critical components becomes increasingly crucial. In the world of engineering and manufacturing, seals and gaskets play a vital role in maintaining system integrity and preventing costly failures. However, their performance can be compromised by extreme temperature fluctuations, leading to catastrophic consequences. This is where Simulating temperature cycles in climate chambers comes into play a laboratory service provided by Eurolab that helps businesses validate the reliability of these critical components.

What is Simulating Temperature Cycles in Climate Chambers?

Simulating temperature cycles in climate chambers involves subjecting seals and gaskets to a series of extreme temperature fluctuations, mimicking real-world conditions. This process allows for the evaluation of their performance under various scenarios, ensuring that they can withstand the rigors of operation without compromising system integrity.

Why is it Essential for Businesses?

In todays fast-paced industrial landscape, companies cannot afford to compromise on quality or risk costly failures. By simulating temperature cycles in climate chambers, businesses can

Mitigate Risk Identify potential weaknesses and vulnerabilities in seals and gaskets before they cause catastrophic failures.

Ensure Reliability Validate the performance of critical components under various operating conditions.

Optimize Design Refine design parameters to meet specific application requirements.

Reduce Maintenance Costs Minimize downtime and maintenance expenses by selecting seals and gaskets that can withstand extreme temperatures.

Advantages of Simulating Temperature Cycles in Climate Chambers

The benefits of simulating temperature cycles in climate chambers are numerous. Some of the key advantages include

Improved Safety By identifying potential weaknesses, companies can take proactive measures to prevent accidents and ensure a safe working environment.

Increased Efficiency Optimized design parameters result in improved system performance, reduced energy consumption, and increased productivity.

Enhanced Reliability Verified performance under various conditions ensures that systems operate consistently, reducing downtime and maintenance costs.

Compliance with Industry Standards Eurolabs climate chamber testing services ensure compliance with industry standards and regulations.

Benefits of Using Climate Chambers to Test Seals and Gaskets

Using climate chambers to test seals and gaskets offers several benefits, including

Accurate Results Climate chambers provide a controlled environment for testing, ensuring accurate results that reflect real-world conditions.

Cost-Effective Simulating temperature cycles in climate chambers is often more cost-effective than conducting field tests or relying on theoretical models.

Time-Efficient Climate chamber testing allows for quick and efficient evaluation of seals and gaskets, reducing development timelines.

QA Frequently Asked Questions

Q What types of materials can be tested using climate chambers?

A Seals and gaskets made from a variety of materials, including rubber, silicone, and metal, can be tested using climate chambers.

Q How long does the testing process typically take?

A The duration of the testing process varies depending on the specific requirements and scope of the project. Typically, it takes anywhere from a few days to several weeks.

Q What kind of temperature fluctuations are simulated in climate chambers?

A Climate chambers can simulate extreme temperature fluctuations, including high-temperature exposure, low-temperature exposure, and cycling between temperatures.

Q Can climate chamber testing be used for other applications beyond seals and gaskets?

A Yes. Climate chamber testing can be applied to a wide range of components and materials, including electronic devices, mechanical parts, and pharmaceutical products.

Conclusion

Simulating temperature cycles in climate chambers is an indispensable tool for businesses seeking to ensure the reliability and durability of critical components. By leveraging Eurolabs state-of-the-art climate chamber facilities, companies can validate the performance of seals and gaskets under various operating conditions, minimizing risk, ensuring efficiency, and optimizing design parameters.

Dont compromise on quality or risk costly failures choose Eurolab for your climate chamber testing needs. Our expert team will work closely with you to develop a customized testing plan that meets your specific requirements.

References

American Society of Mechanical Engineers (ASME). (2020). Pressure Vessel and Piping Code.

International Organization for Standardization (ISO). (2019). ISO 104362019 - Petroleum, petrochemical and natural gas industries - Metallic seals.

Eurolab. (2022). Climate Chamber Testing Services.

Note The references provided are real standards and codes used in the industry, but they should not be considered as actual recommendations for specific testing requirements. Consult with a qualified expert to determine the most suitable testing protocols for your application.