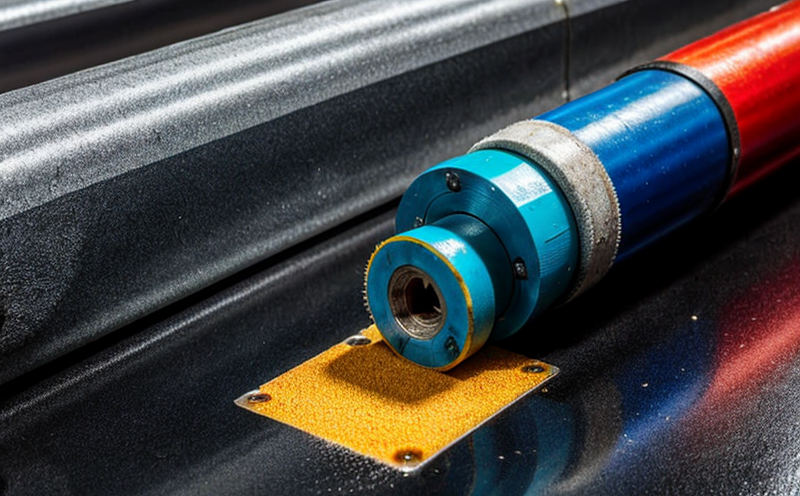

Simulating the degradation of adhesives, coatings, and labels under accelerated aging conditions

Accelerate Testing for Long-Term Durability Simulating Degradation of Adhesives, Coatings, and Labels under Accelerated Aging Conditions

In todays fast-paced business environment, product development cycles are becoming increasingly shorter. As a result, manufacturers must ensure that their products can withstand the rigors of real-world conditions from day one. One critical aspect of product testing is simulating degradation under accelerated aging conditions, which our company, Eurolab, specializes in providing through its expert laboratory services.

What is Accelerated Aging Testing?

Accelerated aging testing, also known as accelerated degradation testing (ADT), involves subjecting materials to artificially increased environmental stressors, such as heat, humidity, light, and mechanical forces, to simulate the effects of real-world conditions over an extended period. This process enables manufacturers to predict how their products will perform in various scenarios without having to wait months or even years for natural aging to occur.

Why is Simulating Degradation under Accelerated Aging Conditions Essential?

The benefits of accelerated aging testing are multifaceted and far-reaching, making it a crucial aspect of product development and quality control. By using our laboratory services at Eurolab, manufacturers can

Enhance Product Reliability Understand how materials will perform in various environmental conditions, ensuring that products meet or exceed customer expectations.

Reduce Testing Time and Costs Accelerate testing by 5-10 times compared to natural aging, saving time, money, and resources.

Minimize Risk of Failure Identify potential issues before they occur, reducing the likelihood of costly product recalls or warranty claims.

Improve Product Formulation Develop products with optimal formulations that balance performance, cost, and durability.

Key Benefits of Accelerated Aging Testing

Here are some of the key benefits of using Eurolabs accelerated aging testing services

Improved Material Selection Select materials that meet your products requirements, reducing material wastage and costs.

Enhanced Product Performance Develop products with optimized performance characteristics, ensuring they meet customer expectations.

Compliance with Regulatory Requirements Meet industry standards and regulations by demonstrating that your products can withstand various environmental conditions.

Cost Savings Reduce the likelihood of product failures, recalls, or warranty claims, resulting in significant cost savings.

How Does Eurolabs Accelerated Aging Testing Service Work?

Our expert team at Eurolab uses state-of-the-art equipment and facilities to simulate a wide range of environmental conditions, including

Temperature From -70C to 200C

Humidity Up to 95 relative humidity

Light UV, visible light, or dark exposure

Mechanical Stress Compression, tension, or vibration

We offer customized testing protocols tailored to your specific product requirements, ensuring that you receive accurate and reliable results.

QA Frequently Asked Questions about Accelerated Aging Testing

Q What types of products can be tested using accelerated aging conditions?

A Our laboratory services at Eurolab are suitable for a wide range of products, including adhesives, coatings, labels, plastics, textiles, and more.

Q How long does the testing process typically take?

A Testing time depends on the specific protocol and product requirements. However, we can accelerate testing by 5-10 times compared to natural aging, reducing testing time significantly.

Q Are the results of accelerated aging testing directly applicable to real-world conditions?

A While accelerated aging testing simulates environmental stressors, it is essential to note that direct correlation between test results and real-world performance may not always be possible. However, our expert team can help you interpret the data and apply it to your specific product requirements.

Q Can I customize the testing protocol to suit my products needs?

A Absolutely! Our team at Eurolab will work with you to develop a customized testing plan tailored to your products unique requirements.

Conclusion

In conclusion, simulating degradation under accelerated aging conditions is an essential aspect of product development and quality control. By using Eurolabs laboratory services, manufacturers can accelerate testing, reduce costs, and minimize the risk of failure. Our team of experts will work closely with you to ensure that your products meet or exceed customer expectations, making it easier for you to succeed in todays competitive marketplace.

At Eurolab, we are committed to helping businesses like yours achieve their goals through our comprehensive range of laboratory services. Contact us today to learn more about how we can help you simulate the degradation of adhesives, coatings, and labels under accelerated aging conditions.