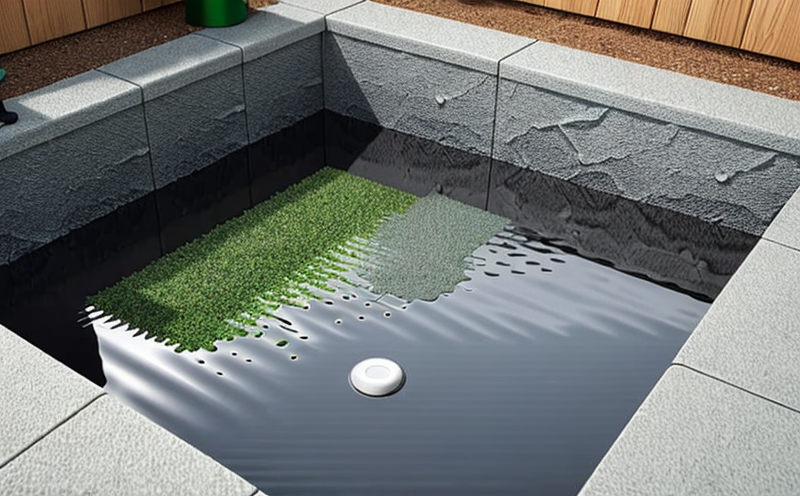

Simulating water exposure to materials to assess how well they resist moisture infiltration

The Crucial Role of Water Exposure Testing in Ensuring Material Durability Why Businesses Cant Afford to Ignore It

In todays fast-paced and competitive business landscape, companies are constantly seeking innovative ways to improve product performance, reduce costs, and enhance customer satisfaction. One critical aspect that often gets overlooked is the assessment of materials resistance to moisture infiltration. Water exposure can have a devastating impact on products, causing damage, degradation, and even catastrophic failure. Thats where Simulating water exposure to materials to assess how well they resist moisture infiltration comes in a cutting-edge laboratory service offered by Eurolab that helps businesses safeguard their products against the perils of moisture.

What is Simulating Water Exposure Testing?

Simulating water exposure testing involves subjecting materials or products to controlled conditions that mimic real-world exposure to water. This can include various forms of water, such as distilled water, sea water, or even industrial wastewater. By replicating the same environmental conditions that your product will face in service, we can assess its ability to withstand moisture infiltration and resist degradation.

Why is Simulating Water Exposure Testing Essential for Businesses?

The advantages of using Simulating water exposure testing are numerous and far-reaching. Here are just a few key benefits

Ensure Product Reliability By assessing your materials resistance to moisture, you can guarantee that it will perform as expected in real-world conditions.

Reduce Warranty Claims Products that withstand moisture exposure are less likely to require costly repairs or replacements, minimizing warranty claims and associated expenses.

Comply with Regulatory Requirements Many industries have strict regulations regarding product durability and safety. Our testing services help ensure compliance with these standards.

Enhance Customer Satisfaction Products that resist water damage are more likely to meet customer expectations, leading to increased satisfaction and loyalty.

Key Benefits of Simulating Water Exposure Testing

Here are some key benefits of using our Simulating water exposure testing service

Accurate Results Our state-of-the-art equipment and expert technicians ensure accurate results every time.

Customized Testing Plans We work closely with you to create a customized testing plan that meets your specific needs and requirements.

Rapid Turnaround Times Our experienced team ensures quick turnaround times, minimizing downtime and maximizing productivity.

Comprehensive Reporting Detailed reports provide clear insights into your materials performance, helping you make informed decisions about product development.

Frequently Asked Questions (FAQs)

Weve compiled a list of frequently asked questions to help address any concerns you may have

Q What types of materials can be tested?

A Our testing services cater to a wide range of materials, including metals, plastics, composites, and more.

Q How does the testing process work?

A We work closely with you to develop a customized testing plan. Our experienced technicians then subject your material to controlled conditions that simulate real-world water exposure.

Q What types of water can be used in the testing process?

A We use various forms of water, including distilled water, sea water, and industrial wastewater.

Q Can I get immediate results after testing?

A While our standard turnaround times are quick, some tests may require more time to complete. Our team will provide you with a detailed timeline and report as soon as possible.

Q Will the testing process damage my material?

A Our expert technicians take every precaution to ensure that your material is handled and tested safely. In most cases, materials can be returned in their original condition after testing.

Conclusion

Simulating water exposure testing is an essential service that helps businesses safeguard their products against moisture-related issues. By partnering with Eurolab, you can ensure product reliability, reduce warranty claims, comply with regulatory requirements, and enhance customer satisfaction. Dont let moisture stand between your business and success choose our Simulating water exposure testing services today.

About Eurolab

Eurolab is a leading provider of laboratory services specializing in materials testing and analysis. With a team of expert technicians and state-of-the-art equipment, we offer customized solutions for businesses seeking to improve product performance, reduce costs, and enhance customer satisfaction. Trust us to help you navigate the complexities of material durability and achieve your business goals.

-

Testing the ability of building materials to prevent water penetration and moisture damage

-

Ensuring that roofing, foundations, and walls are protected from water damage by waterproofing materials

-

Verifying that materials such as membranes, coatings, and sealants are effective against water infiltration

-

Testing materials for their resistance to water absorption, swelling, or degradation over time

-

Simulating rain, snow, and humidity to evaluate how materials perform in wet conditions

-

Ensuring that materials used in basements or exterior walls prevent water from entering the building

-

Evaluating how waterproof coatings protect structures in extreme weather conditions

-

Testing waterproof materials for long-term durability and their ability to resist environmental stressors

-

Verifying that construction materials remain dry and unaffected by moisture or water exposure

-

Ensuring that waterproofing systems provide adequate drainage to prevent moisture buildup

-

Testing the resistance of materials to various forms of water, including fresh, salt, and chemical exposure

-

Simulating flooding conditions to assess how building materials handle excessive water pressure

-

Ensuring that waterproofing materials are easy to apply and provide consistent protection

-

Evaluating the adhesion of waterproof membranes to various building surfaces, ensuring long-term effectiveness

-

Verifying that materials used in waterproofing do not degrade under UV exposure or temperature fluctuations

-

Testing for resistance to condensation or vapor transmission that could lead to moisture issues

-

Ensuring that the waterproofing materials are compatible with other building components for seamless protection

-

Testing for the integrity of seals and joints to prevent water leakage between different building elements

-

Simulating the effects of water pooling to evaluate whether waterproof materials remain effective

-

Testing the impact of construction and environmental stress on the longevity of waterproof coatings

-

Ensuring that waterproofing solutions can handle seasonal changes in moisture levels without failing