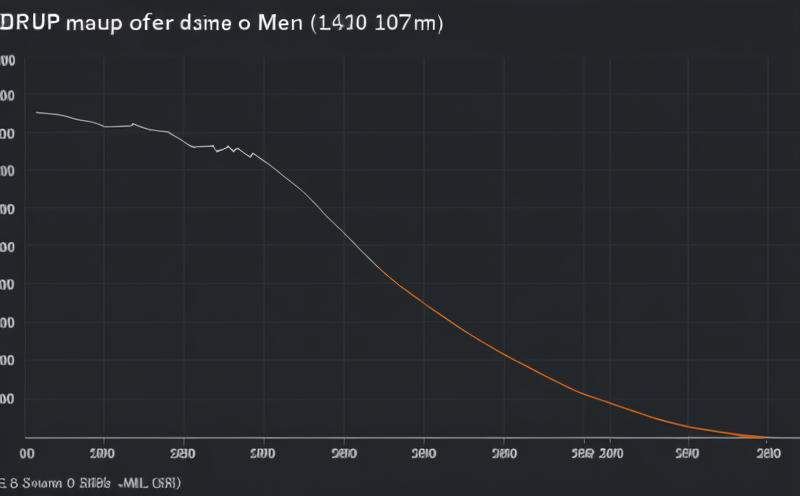

Simulation of Drop Damage Over Time

The Power of Predictive Testing How Simulation of Drop Damage Over Time Can Revolutionize Your Business

In todays fast-paced and competitive business landscape, product reliability and durability have become the linchpins of success. A single design flaw or manufacturing defect can lead to costly recalls, damaged brand reputation, and ultimately, financial losses. This is where Simulation of Drop Damage Over Time comes into play a cutting-edge laboratory service that empowers businesses to predict and prevent damage from drops.

As a pioneering company in the field of materials testing, Eurolab offers this sophisticated simulation technology to help manufacturers, designers, and researchers accurately assess the susceptibility of their products to drop damage over time. By leveraging our expertise and state-of-the-art facilities, you can make informed decisions about material selection, product design, and manufacturing processes ensuring that your creations meet the highest standards of reliability and performance.

Advantages of Simulation of Drop Damage Over Time

Simulation of Drop Damage Over Time is an indispensable tool for businesses seeking to optimize their products durability and minimize potential liabilities. By adopting this approach, you can enjoy numerous benefits, including

Reduced Product Failures Simulation of drop damage over time enables you to identify areas where your product may be prone to failure due to impact or vibration. This knowledge allows you to proactively redesign or modify your product to mitigate these risks.

Increased Efficiency and Cost Savings By simulating the effects of repeated drops on various materials, you can optimize your production processes, eliminate unnecessary steps, and reduce costs associated with rework, recalls, or warranty claims.

Improved Material Selection and Formulation Our advanced simulation capabilities allow you to test and compare different material combinations, formulations, or coatings. This enables you to make informed decisions about the optimal materials for your product, ensuring superior durability and performance.

Enhanced Brand Reputation and Customer Trust When your products demonstrate exceptional reliability and longevity, customers are more likely to trust your brand and recommend it to others. By leveraging Simulation of Drop Damage Over Time, you can enhance your reputation as a company committed to delivering high-quality products that exceed customer expectations.

Key Benefits of Eurolabs Simulation of Drop Damage Over Time Service

Our expert team at Eurolab has developed a comprehensive service package designed to meet the unique needs of each client. The key benefits of our simulation capabilities include

Advanced Testing and Analysis Our state-of-the-art equipment and software enable us to simulate drop damage over time with unprecedented accuracy, taking into account various factors such as impact velocity, angle of incidence, and material properties.

Customized Solutions for Your Business We work closely with clients to understand their specific requirements, product goals, and performance objectives. Our tailored approach ensures that our simulation results accurately reflect your unique needs.

Rapid Turnaround Times Eurolabs streamlined processes and dedicated staff enable us to deliver high-quality results quickly, minimizing downtime and allowing you to make informed decisions in a timely manner.

Frequently Asked Questions

We understand that you may have questions about Simulation of Drop Damage Over Time and how it can benefit your business. Here are some answers to common queries

Q What types of products can be tested using Simulation of Drop Damage Over Time?

A Our simulation capabilities are applicable to a wide range of products, including electronics, automotive components, medical devices, consumer goods, and more.

Q How does Simulation of Drop Damage Over Time differ from physical drop testing?

A While physical drop testing can be effective in certain situations, it often has limitations due to costs, time constraints, and the potential for damage or destruction. Our simulation technology offers a more cost-effective, efficient, and repeatable way to evaluate product durability.

Q Can I integrate Simulation of Drop Damage Over Time into my existing design process?

A Absolutely! We encourage collaboration with our clients design teams to ensure seamless integration of our simulation results into your development workflow.

Q What kind of support can I expect from Eurolabs team during the simulation process?

A Our expert staff is dedicated to providing personalized support throughout the project. Youll have access to regular progress updates, data analysis, and consultation on interpretation and implementation of simulation results.

Unlock the Full Potential of Your Products with Simulation of Drop Damage Over Time

In todays competitive market, businesses must be proactive in ensuring their products meet the highest standards of reliability and durability. By partnering with Eurolab for Simulation of Drop Damage Over Time, you can

Mitigate risks associated with product failures

Optimize production processes and reduce costs

Enhance your brand reputation through improved product performance

Stay ahead of the competition by adopting cutting-edge testing and analysis techniques

Dont let material or design flaws compromise your products success. Contact Eurolab today to discover how Simulation of Drop Damage Over Time can revolutionize your business and drive innovation in the field of materials testing.