Surface Coating Integrity

Unlocking Surface Coating Integrity The Key to Ensuring Product Reliability

In todays fast-paced and highly competitive business landscape, companies are constantly seeking ways to optimize their operations and maintain a competitive edge. One crucial aspect of achieving this goal is ensuring the integrity of surface coatings on various products. Surface Coating Integrity, a laboratory service provided by Eurolab, plays a vital role in guaranteeing product reliability and safety.

What is Surface Coating Integrity?

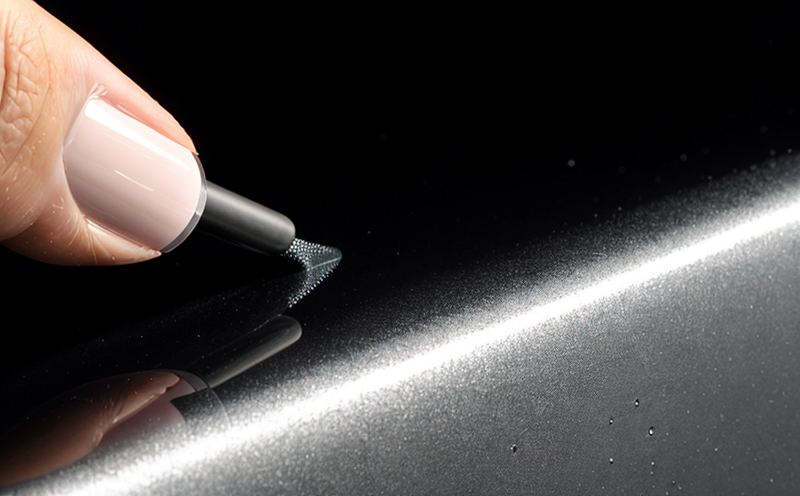

Surface Coating Integrity refers to the evaluation of the performance and characteristics of surface coatings on materials such as metals, plastics, and composites. These coatings can be applied for various purposes, including corrosion resistance, wear protection, lubrication, or aesthetic enhancement. The integrity of these coatings is critical in ensuring that products meet regulatory requirements, industry standards, and customer expectations.

Why is Surface Coating Integrity Essential?

In the absence of a thorough evaluation of surface coating integrity, businesses can face significant risks, including

Product failures Coatings that fail to perform as intended can lead to product failure, resulting in costly recalls, reputation damage, and potential lawsuits.

Regulatory non-compliance Inadequate coatings can compromise products compliance with industry standards and regulations, subjecting companies to fines and penalties.

Customer dissatisfaction Ineffective or damaged coatings can lead to customer complaints, low product satisfaction rates, and ultimately, loss of market share.

The Benefits of Surface Coating Integrity Services by Eurolab

By partnering with Eurolab for Surface Coating Integrity services, businesses can enjoy numerous benefits that enhance their products quality, reliability, and safety. Some key advantages include

Improved product performance Thorough evaluation of surface coatings ensures that they meet the required specifications, resulting in enhanced product functionality.

Enhanced customer satisfaction By guaranteeing product reliability and safety, companies can increase customer trust and loyalty.

Increased regulatory compliance Surface Coating Integrity services help businesses meet industry standards and regulatory requirements, reducing the risk of non-compliance.

Cost savings Avoidance of costly recalls, replacements, or repairs due to coating failures ensures significant cost savings.

Competitive edge Demonstrating a commitment to product integrity and quality can differentiate companies from competitors and enhance their reputation.

Key Benefits at a Glance

Here are the key benefits of Eurolabs Surface Coating Integrity services

Comprehensive testing Our laboratory experts conduct thorough evaluations of surface coatings, including adhesion, wear resistance, corrosion protection, and more.

Customized solutions We tailor our services to meet specific industry requirements, ensuring that products meet exacting standards.

Accurate reporting Detailed reports provide actionable insights for optimizing product design, manufacturing processes, and maintenance protocols.

Expert analysis Our laboratory experts interpret results, providing valuable recommendations for improving surface coating performance.

Rapid turnaround times We prioritize expedited testing to minimize production delays.

QA Surface Coating Integrity Services by Eurolab

Q1 What is the purpose of evaluating surface coatings?

A1 Evaluating surface coatings ensures that products meet required specifications, industry standards, and regulatory requirements. This guarantees product reliability, safety, and performance.

Q2 How does Eurolab ensure Surface Coating Integrity services are tailored to our specific needs?

A2 We collaborate with clients to understand their unique requirements, including industry-specific regulations, product applications, and desired outcomes. Our laboratory experts then design customized testing protocols to meet these needs.

Q3 What types of surface coatings can be evaluated using Eurolabs Surface Coating Integrity services?

A3 Our services cater to various types of surface coatings, including paints, primers, clear coats, inks, and lubricants. We also evaluate coatings on materials such as metals, plastics, composites, and more.

Q4 What information will I receive after the testing process is completed?

A4 Youll receive a comprehensive report detailing test results, along with expert analysis and recommendations for optimizing surface coating performance. This enables informed decision-making to improve product design, manufacturing processes, and maintenance protocols.

Conclusion

In todays fast-paced business environment, ensuring Surface Coating Integrity is no longer an option; its a necessity. By partnering with Eurolab for laboratory services, companies can guarantee the reliability, safety, and performance of their products. With our expertise, customized solutions, and rapid turnaround times, businesses can unlock the full potential of their products while minimizing risks associated with surface coating failures.

Experience the Eurolab difference Join the ranks of industry leaders who rely on us for Surface Coating Integrity services that ensure product excellence and safety.

Trust Eurolab to guarantee your products integrity.