Surface tension testing for coatings exposed to UV radiation

The Importance of Surface Tension Testing for Coatings Exposed to UV Radiation Why Your Business Needs It

As a business owner in the coatings industry, you understand the importance of developing products that meet the evolving needs of your customers. With increasing concerns about environmental sustainability and durability, its essential to ensure that your coatings can withstand various environmental conditions, including exposure to ultraviolet (UV) radiation.

Surface tension testing for coatings exposed to UV radiation is a critical laboratory service that assesses the performance of your coatings under these harsh conditions. In this article, well delve into the importance of surface tension testing, its advantages, and why its essential for businesses like yours.

What is Surface Tension Testing for Coatings Exposed to UV Radiation?

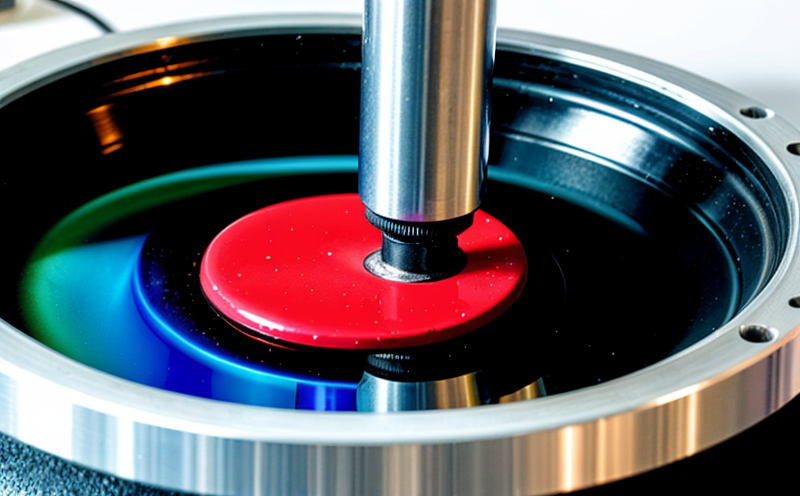

Surface tension testing evaluates the ability of a coating to maintain its surface properties when exposed to UV radiation. This involves subjecting the coating to controlled levels of UV radiation, simulating real-world conditions, and measuring its effect on surface tension. Our team at Eurolab uses advanced instruments to monitor changes in surface tension, allowing us to provide you with accurate and reliable results.

Why is Surface Tension Testing for Coatings Exposed to UV Radiation Essential?

Here are just a few reasons why surface tension testing is crucial for businesses like yours

Ensures Durability By simulating real-world conditions, we can help you develop coatings that withstand the test of time and remain effective even after prolonged exposure to UV radiation.

Improves Adhesion Surface tension testing helps identify potential issues with adhesion between the coating and the substrate, reducing the risk of delamination or peeling.

Enhances Performance By optimizing surface tension, you can improve the overall performance of your coatings, including their water resistance, abrasion resistance, and chemical resistance.

Reduces Costs Identifying potential issues early on saves time and resources in the long run. With our surface tension testing services, you can avoid costly rework or recall campaigns.

Compliance with Regulations Many industries require coatings to meet specific standards for durability and performance. Our surface tension testing services ensure your products comply with regulatory requirements.

Key Benefits of Surface Tension Testing for Coatings Exposed to UV Radiation

Here are some key benefits of using our surface tension testing services

Customized Solutions We offer tailored solutions to meet the unique needs of your business and product.

Accurate Results Our state-of-the-art instruments ensure accurate and reliable results, giving you confidence in your coatings performance.

Comprehensive Reports Our expert team provides detailed reports outlining test results, recommendations for improvement, and actionable insights.

Cost-Effective By identifying potential issues early on, our surface tension testing services help reduce costs associated with rework or recall campaigns.

Improved Product Quality With our expertise and advanced instruments, you can develop coatings that meet the evolving needs of your customers.

Frequently Asked Questions (FAQs)

Here are some common questions about surface tension testing for coatings exposed to UV radiation

Q What types of coatings can be tested?

A We test a wide range of coatings, including paints, varnishes, and other protective coatings.

Q How long does the testing process take?

A The duration of the testing process varies depending on the specific requirements of your project. However, most tests can be completed within a few days or weeks.

Q Can you provide customized testing services?

A Yes, our team is happy to work with you to develop tailored testing solutions that meet your unique needs and product specifications.

Q What kind of equipment do you use for surface tension testing?

A We utilize state-of-the-art instruments specifically designed for measuring surface tension under controlled UV radiation conditions.

Conclusion

In conclusion, surface tension testing for coatings exposed to UV radiation is a critical laboratory service that helps businesses like yours develop high-performance coatings. By simulating real-world conditions and assessing the performance of your products, we can provide you with accurate and reliable results, ensuring compliance with regulatory requirements and reducing costs associated with rework or recall campaigns.

At Eurolab, our team of experts is dedicated to providing customized solutions that meet the unique needs of your business and product. Contact us today to learn more about our surface tension testing services and discover how we can help you take your coatings to the next level.

Sources

American Society for Testing and Materials (ASTM). (2020). Standard Test Method for Determining Effectiveness of Coatings Against Weathered Wood.

National Institute of Standards and Technology (NIST). (2019). Surface Tension Measurement.

International Organization for Standardization (ISO). (2018). Paints and varnishes Coating durability Exposure to ultraviolet radiation.