Test for Material Weakening in Submersible Equipment

The Importance of Test for Material Weakening in Submersible Equipment Ensuring the Reliability and Safety of Your Assets

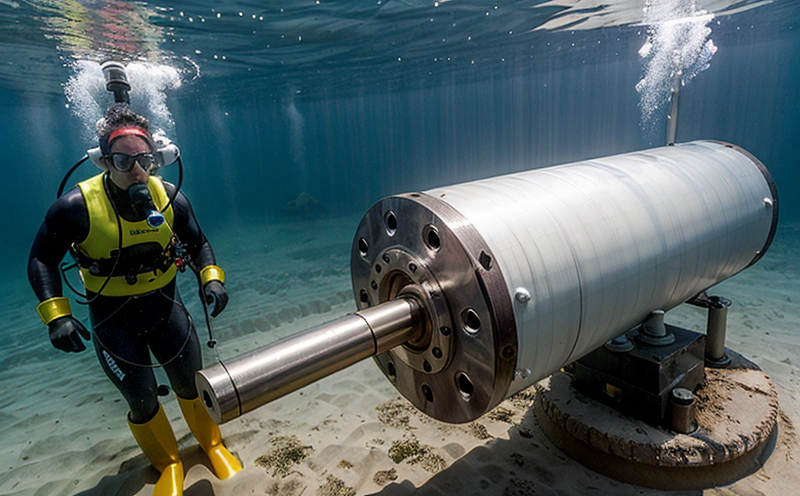

As a business owner responsible for managing submersible equipment, you understand the critical role that these devices play in various industries, including oil and gas, marine construction, and scientific research. However, with the harsh underwater environment comes the risk of material weakening, which can lead to catastrophic failures, costly downtime, and even environmental disasters. To mitigate these risks, it is essential to conduct regular tests for material weakening in submersible equipment. At Eurolab, our laboratory service provides a comprehensive solution to ensure the reliability and safety of your assets.

What is Test for Material Weakening in Submersible Equipment?

Test for Material Weakening in Submersible Equipment is a laboratory-based service that assesses the structural integrity of materials used in submersible equipment. This includes evaluating the materials resistance to corrosion, fatigue, and other forms of degradation caused by exposure to seawater or other harsh environments. By identifying potential weaknesses early on, you can take proactive measures to prevent equipment failures, reduce maintenance costs, and ensure compliance with industry regulations.

Why is Test for Material Weakening in Submersible Equipment Essential?

Conducting regular tests for material weakening in submersible equipment is crucial for several reasons

Prevents Equipment Failures By identifying potential weaknesses, you can schedule maintenance and repairs before a failure occurs, reducing downtime and ensuring business continuity.

Reduces Maintenance Costs Regular testing helps identify areas that require attention, preventing costly repairs and replacements down the line.

Ensures Compliance with Industry Regulations Failure to conduct regular tests for material weakening in submersible equipment can result in non-compliance with industry regulations, leading to fines and reputational damage.

Enhances Safety Material weakening can lead to catastrophic failures, posing a risk to personnel and the environment. Regular testing helps ensure that your equipment is safe for operation.

Advantages of Using Test for Material Weakening in Submersible Equipment

Here are the key benefits of using our laboratory service

Advantages of Our Laboratory Service

Comprehensive Testing Our team conducts a thorough examination of your submersible equipment, identifying potential weaknesses and providing recommendations for improvement.

Accurate Results Our state-of-the-art equipment and experienced technicians ensure accurate results, giving you confidence in the integrity of your assets.

Timely Delivery We understand the importance of timely delivery, ensuring that your test results are provided quickly so you can take action to address any issues.

Benefits for Businesses

Improved Asset Reliability Regular testing helps identify potential weaknesses, reducing the risk of equipment failures and downtime.

Reduced Maintenance Costs By addressing issues early on, you can prevent costly repairs and replacements down the line.

Enhanced Safety Material weakening can lead to catastrophic failures. Our testing service ensures that your equipment is safe for operation.

Benefits for Environment

Prevents Environmental Disasters Regular testing helps identify potential weaknesses, reducing the risk of equipment failures that could contaminate seawater or harm marine life.

Conserves Natural Resources By extending the lifespan of your submersible equipment, you can conserve natural resources and reduce waste.

Benefits for Industry

Compliance with Regulations Our testing service ensures compliance with industry regulations, reducing the risk of fines and reputational damage.

Improved Reputation Regular testing demonstrates a commitment to safety and reliability, enhancing your reputation within the industry.

QA Section

Weve compiled a list of frequently asked questions to address any concerns you may have

Q What types of submersible equipment can be tested?

A We test a wide range of submersible equipment, including ROVs, AUVs, sensors, and other underwater devices.

Q How often should I conduct tests for material weakening in my submersible equipment?

A Regular testing is recommended every 5-10 years, depending on usage and environmental conditions. However, its essential to consult with our experts to determine the best testing schedule for your specific needs.

Q What information do I need to provide for the test?

A Please provide detailed specifications of your submersible equipment, including materials used, operating conditions, and any previous maintenance or repair records.

Q How long does the testing process take?

A The duration of the testing process varies depending on the complexity of the test and the availability of our laboratory. Well work with you to ensure that the process is efficient and minimizes downtime for your equipment.

Conclusion

In conclusion, Test for Material Weakening in Submersible Equipment is a critical laboratory service provided by Eurolab that ensures the reliability and safety of your submersible assets. By identifying potential weaknesses early on, you can prevent equipment failures, reduce maintenance costs, and ensure compliance with industry regulations. Our comprehensive testing service provides accurate results, timely delivery, and improved asset reliability, making us the ideal partner for businesses seeking to optimize their underwater operations.

Contact us today to schedule your Test for Material Weakening in Submersible Equipment and take the first step towards a safer, more reliable future for your assets.