Testing for Cracking and Fracture Points in Mobility Frames

The Crucial Importance of Testing for Cracking and Fracture Points in Mobility Frames Why Eurolabs Expertise Matters

In todays fast-paced manufacturing landscape, businesses face numerous challenges in ensuring the quality and reliability of their products. One critical aspect that often goes unnoticed is the integrity of mobility frames a crucial component found in various industries such as medical devices, wheelchairs, and strollers. Cracking and fracture points can lead to catastrophic failures, compromising safety and damaging reputations. Thats where Eurolab comes in our state-of-the-art laboratory service specializes in Testing for Cracking and Fracture Points in Mobility Frames.

What is Testing for Cracking and Fracture Points in Mobility Frames?

Testing for cracking and fracture points in mobility frames involves a rigorous series of tests designed to simulate real-world conditions, identifying potential weaknesses in the frames structure. Our team of experts utilizes advanced equipment and techniques to subject samples to various stresses, evaluating their ability to withstand pressure, fatigue, and impact.

Why is Testing for Cracking and Fracture Points in Mobility Frames Essential?

In an industry where product liability and regulatory compliance are paramount, failure to identify cracking and fracture points can have severe consequences. Here are just a few reasons why Eurolabs expert testing services are indispensable

Key Benefits of Using Eurolabs Testing Services

Improved Product Safety By detecting potential weaknesses in mobility frames, businesses can prevent accidents, injuries, and fatalities protecting users and maintaining a strong reputation.

Enhanced Compliance with Regulations Our tests adhere to international standards (e.g., ISO 10993-7), ensuring compliance with regulatory requirements and avoiding costly fines or product recalls.

Increased Customer Confidence By demonstrating a commitment to quality and safety, businesses can boost customer loyalty, retention rates, and market share.

Reduced Warranty and Liability Costs Identifying cracking and fracture points early on enables manufacturers to rectify issues before they become major problems, saving time, money, and resources.

How Our Testing Services Work

At Eurolab, we employ a multi-step approach to identify cracking and fracture points in mobility frames

Sample Collection and Preparation We work closely with clients to collect representative samples from production lines or existing products.

Mechanical Testing Using advanced equipment (e.g., universal testing machines), our experts subject samples to various loads, including tension, compression, and flexure.

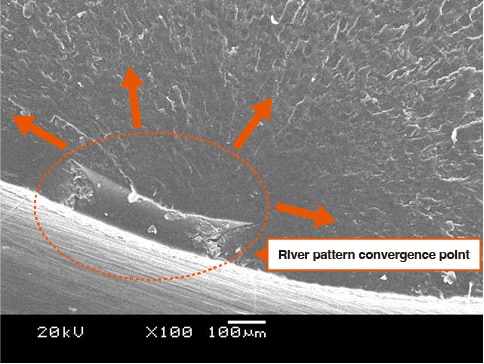

Visual Inspection and Microscopy Our team conducts thorough visual inspections and uses microscopy techniques to detect any visible signs of cracking or fracture points.

Data Analysis and Reporting We provide detailed reports highlighting test results, identifying areas of concern, and offering recommendations for improvement.

QA Frequently Asked Questions

Q What types of mobility frames can be tested?

A Our services cater to a wide range of mobility frames, including those used in wheelchairs, strollers, medical devices, and other applications.

Q How do I prepare samples for testing?

A We provide comprehensive guidelines on sample collection, preparation, and submission. Our team will work closely with you to ensure smooth testing procedures.

Q What is the typical turnaround time for test results?

A Depending on the scope of tests and sample availability, our average turnaround time ranges from 3-7 business days.

Q Can Eurolabs testing services be customized to meet specific industry requirements?

A Yes! Our team collaborates with clients to tailor our services according to unique needs, ensuring compliance with industry-specific regulations and standards.

Conclusion

In todays competitive landscape, manufacturers cannot afford to compromise on product quality or safety. By partnering with Eurolab for Testing for Cracking and Fracture Points in Mobility Frames, businesses can ensure the integrity of their products, maintain regulatory compliance, and build customer confidence. Dont wait until its too late trust our experts to help you navigate the complexities of mobility frame testing.

By choosing Eurolabs expert services, youll not only safeguard your brand reputation but also stay ahead of the competition in a rapidly evolving market.