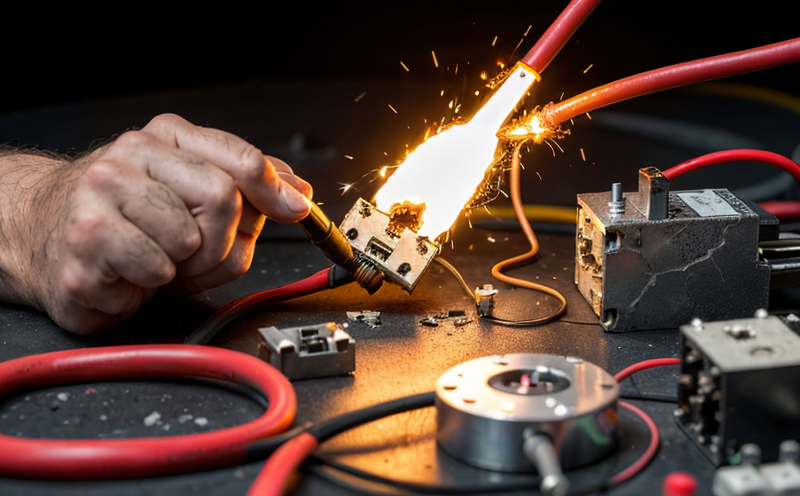

Testing for damage to electrical components after impact, including circuits and connectors.

The Importance of Testing for Damage to Electrical Components after Impact A Crucial Service Provided by Eurolab

In todays fast-paced and technology-driven world, electrical components are an integral part of our daily lives. From smartphones and laptops to industrial machinery and vehicles, electrical systems play a vital role in keeping us connected, productive, and safe. However, with great power comes great responsibility and that includes the risk of damage from impact.

Physical impacts can cause irreparable harm to electrical components, leading to malfunctions, equipment failure, and even catastrophic consequences. This is where Eurolabs laboratory service comes in a vital tool for businesses seeking to ensure their electrical systems are safe, reliable, and compliant with industry standards.

What is Testing for Damage to Electrical Components after Impact?

Testing for damage to electrical components after impact involves conducting thorough examinations of circuits, connectors, and other electrical parts to detect any signs of physical stress or damage. This service is essential for businesses that rely on high-performance electrical systems, as it helps identify potential problems before they become major issues.

Eurolabs laboratory service utilizes state-of-the-art equipment and expert technicians to analyze electrical components after an impact event. Our team will carefully inspect each component, taking into account the nature of the impact, the type of material involved, and the environmental conditions at the time of the incident.

Why is Testing for Damage to Electrical Components after Impact Essential?

In todays competitive market, businesses cannot afford to compromise on safety and efficiency. Here are just a few compelling reasons why testing for damage to electrical components after impact is crucial

Prevents Equipment Failure Regular inspections can help identify potential problems before they cause equipment failure, reducing downtime and lost productivity.

Ensures Compliance with Industry Standards By detecting any signs of physical stress or damage, Eurolabs laboratory service helps businesses meet regulatory requirements and maintain a safe working environment.

Reduces Risk of Accidents and Injuries A thorough examination can identify potential hazards, minimizing the risk of accidents and injuries to personnel and property.

Protects Brand Reputation Demonstrating a commitment to safety and quality through regular testing and inspections can boost customer confidence and protect your brand reputation.

Key Benefits of Using Eurolabs Laboratory Service

Here are just some of the key benefits of using Eurolabs laboratory service for testing electrical components after impact

Accurate Results Our team utilizes advanced equipment and expert techniques to provide accurate results, giving you peace of mind that your electrical systems are safe and reliable.

Comprehensive Analysis We examine each component thoroughly, taking into account the specific circumstances surrounding the impact event.

Customized Solutions Our laboratory service is tailored to meet the unique needs of your business, providing customized solutions for optimal performance and safety.

Timely Reporting We provide prompt reporting, allowing you to take immediate action if any issues are detected.

Frequently Asked Questions (FAQs)

Here are some common questions about testing electrical components after impact

Q What types of impacts can be tested?

A Our laboratory service can test for damage caused by various types of impacts, including drops, bumps, and vibrations.

Q How long does the testing process take?

A The duration of our laboratory service varies depending on the complexity of the inspection. However, we strive to complete most tests within a few days.

Q What kind of equipment is used for testing?

A Our team utilizes state-of-the-art equipment, including high-resolution microscopes, thermal imaging cameras, and advanced material analysis tools.

Q Can I schedule a test at my facility or do I need to send the components to Eurolab?

A We offer both on-site testing and laboratory-based services. We can work with you to determine the best approach for your specific needs.

Conclusion

Testing for damage to electrical components after impact is an essential service that helps businesses ensure their equipment is safe, reliable, and compliant with industry standards. By choosing Eurolabs laboratory service, you can rest assured that your electrical systems are thoroughly examined by expert technicians using state-of-the-art equipment.

Dont wait until its too late schedule a test today to protect your business, reputation, and personnel from the risks associated with physical impacts on electrical components. Contact us now to learn more about our laboratory service and how we can help you stay ahead in an increasingly competitive market.