Testing for ease of use and reliability in both manual and automatic fastening mechanisms

Unlocking Efficiency Testing for Ease of Use and Reliability in Fastening Mechanisms

In todays fast-paced manufacturing landscape, businesses are constantly seeking innovative ways to optimize production processes, reduce costs, and improve product quality. One critical aspect that often gets overlooked is the performance of manual and automatic fastening mechanisms. These essential components play a vital role in various industries, including automotive, aerospace, construction, and more.

At Eurolab, our team of experts understands the significance of testing fastening mechanisms to ensure ease of use and reliability. By doing so, manufacturers can prevent costly downtime, minimize product defects, and enhance overall efficiency. In this article, well delve into the importance of Testing for Ease of Use and Reliability in Fastening Mechanisms, highlighting the benefits, key advantages, and answers to frequently asked questions.

What is Testing for Ease of Use and Reliability in Fastening Mechanisms?

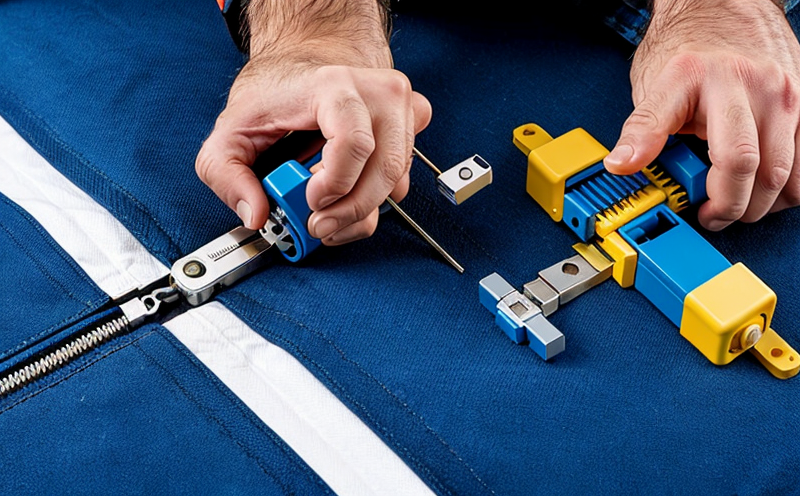

Testing for ease of use and reliability in fastening mechanisms involves evaluating the performance of manual and automatic tools, such as drills, screwdrivers, and riveters. Our expert technicians subject these devices to a range of tests, including

Torque testing measuring the twisting force required to drive screws or bolts

Speed testing assessing the maximum speed at which the mechanism can operate

Vibration testing simulating real-world operating conditions to evaluate durability and stability

Cycle testing repeatedly activating and deactivating the mechanism to assess wear and tear

These comprehensive tests provide manufacturers with valuable insights into the performance, reliability, and ease of use of their fastening mechanisms.

Advantages of Testing for Ease of Use and Reliability in Fastening Mechanisms

By investing in Testing for Ease of Use and Reliability in Fastening Mechanisms, businesses can reap numerous benefits

Reduced Downtime Identify potential issues before they cause equipment failure, minimizing costly downtime and ensuring uninterrupted production.

Improved Product Quality Ensure that fastening mechanisms perform consistently, reducing the likelihood of product defects and enhancing overall quality.

Increased Efficiency Optimize production processes by selecting the most suitable fastening mechanisms for specific applications, leading to increased productivity and reduced labor costs.

Compliance with Industry Standards Meet regulatory requirements and industry standards, such as those set by ISO 9001, by demonstrating a commitment to quality and reliability.

Key Benefits of Testing Fastening Mechanisms

Prevents Equipment Failure Early detection of potential issues minimizes the risk of equipment failure, reducing downtime and associated costs.

Ensures Consistent Performance Regular testing ensures that fastening mechanisms perform consistently, maintaining product quality and meeting regulatory requirements.

Identifies Opportunities for Improvement Testing reveals areas for improvement, enabling manufacturers to optimize production processes and increase efficiency.

Enhances User Experience Easy-to-use fastening mechanisms reduce operator fatigue and error rates, leading to improved overall performance.

Frequently Asked Questions (FAQs)

Q What types of fastening mechanisms can be tested?

A Eurolab tests a wide range of manual and automatic fastening mechanisms, including drills, screwdrivers, riveters, and more.

Q How do I know if my company needs Testing for Ease of Use and Reliability in Fastening Mechanisms?

A If your business relies on efficient production processes, regular testing can help you identify areas for improvement and reduce costs associated with equipment failure and downtime.

Q Can Testing for Ease of Use and Reliability be performed in-house or is it best outsourced to a laboratory like Eurolab?

A While some manufacturers may have the necessary expertise and equipment to perform these tests, outsourcing to a specialized laboratory like Eurolab can provide an independent assessment and ensure accuracy.

Q What are the typical costs associated with Testing for Ease of Use and Reliability in Fastening Mechanisms?

A The cost of testing varies depending on the type and complexity of the mechanism being tested. Our team at Eurolab will work closely with you to develop a customized testing plan that meets your specific needs.

Conclusion

In conclusion, Testing for Ease of Use and Reliability in Fastening Mechanisms is an essential service offered by Eurolab that helps businesses optimize production processes, reduce costs, and improve product quality. By investing in this critical testing process, manufacturers can ensure the reliability and performance of their fastening mechanisms, ultimately driving efficiency and competitiveness in todays market.

At Eurolab, we pride ourselves on providing expert solutions to complex problems. Our team is dedicated to delivering high-quality results that meet or exceed your expectations. Dont compromise on product quality; trust Eurolab for comprehensive Testing for Ease of Use and Reliability in Fastening Mechanisms.

-

Testing the durability and strength of buttons and zippers in consumer products

-

Assessing the resistance of buttons and zippers to repeated use and wear over time

-

Simulating stress conditions to evaluate the reliability of fasteners like buttons and zippers in apparel and bags

-

Testing for breakage or malfunction in buttons and zippers after repeated opening and closing

-

Evaluating the stitching and attachment integrity of buttons and zippers to ensure secure fastening

-

Simulating real-world conditions to assess how buttons and zippers perform under mechanical stress

-

Testing the tensile strength of zipper teeth and buttons to ensure they remain functional over time

-

Assessing the durability of button and zipper materials, such as plastic, metal, or fabric

-

Verifying that zippers maintain their smooth function without snagging or breaking during use

-

Testing the performance of buttons and zippers under varying temperature and humidity conditions

-

Evaluating the impact of pressure or force on the fastening mechanism, ensuring buttons and zippers stay secure

-

Testing for rust, corrosion, or material degradation in metal buttons and zippers exposed to moisture

-

Simulating high-frequency use of buttons and zippers in products like jackets, backpacks, and luggage

-

Verifying that zippers function without failure in heavy-duty or industrial-use products

-

Assessing button and zipper functionality under extreme wear conditions such as high friction

-

Evaluating the strength of zippers and buttons used in consumer products for children or infants

-

Simulating exposure to various environmental factors like dirt, oil, and chemicals on button and zipper performance

-

Assessing the aesthetic durability of buttons and zippers, ensuring they retain their appearance after use

-

Verifying that products with buttons or zippers meet safety standards to prevent choking or injury