Testing for errors introduced by mechanical wear or component degradation

The Crucial Role of Testing for Errors Introduced by Mechanical Wear or Component Degradation in Ensuring Business Efficiency

In todays fast-paced industrial landscape, equipment failure and downtime can have a devastating impact on businesses. Mechanical wear and component degradation are common causes of equipment malfunction, leading to reduced productivity, increased maintenance costs, and compromised safety standards. However, with the advent of advanced testing technologies, companies like Eurolab offer a laboratory service that helps organizations identify and address errors introduced by mechanical wear or component degradation before they become major issues.

What is Testing for Errors Introduced by Mechanical Wear or Component Degradation?

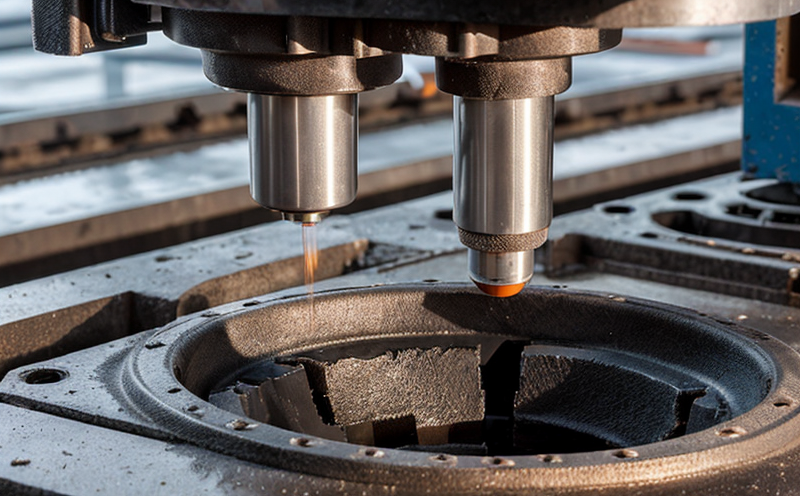

Testing for errors introduced by mechanical wear or component degradation involves analyzing the physical properties of equipment components to detect signs of degradation, such as corrosion, fatigue, or wear. This laboratory service provides a comprehensive assessment of an equipments condition, helping businesses identify potential issues before they cause equipment failure.

At Eurolab, our team of expert technicians utilizes cutting-edge testing technologies and techniques to analyze the chemical, physical, and mechanical properties of equipment components. By identifying errors introduced by mechanical wear or component degradation, we enable companies to take proactive measures to prevent equipment malfunction, minimize downtime, and optimize maintenance schedules.

Advantages of Testing for Errors Introduced by Mechanical Wear or Component Degradation

The benefits of testing for errors introduced by mechanical wear or component degradation are numerous and significant. Here are some key advantages

Reduced Downtime By identifying potential issues before they cause equipment failure, businesses can schedule maintenance during planned downtime, minimizing the impact on production schedules.

Improved Equipment Reliability Regular testing helps ensure that equipment is functioning optimally, reducing the risk of unexpected failures and extending its lifespan.

Increased Safety Identifying errors introduced by mechanical wear or component degradation can help prevent accidents caused by faulty equipment.

Enhanced Maintenance Scheduling Testing provides valuable insights into equipment condition, enabling businesses to optimize maintenance schedules and allocate resources more effectively.

Cost Savings By preventing unexpected failures and minimizing downtime, companies can reduce maintenance costs and avoid the financial burden of repairing or replacing damaged equipment.

Key Benefits in Bullet Points

Identifies potential issues before they cause equipment failure

Reduces downtime and minimizes its impact on production schedules

Ensures equipment is functioning optimally

Enhances safety standards by preventing accidents caused by faulty equipment

Optimizes maintenance scheduling and resource allocation

QA Frequently Asked Questions about Testing for Errors Introduced by Mechanical Wear or Component Degradation

Q How does testing for errors introduced by mechanical wear or component degradation work?

A Our team of expert technicians uses advanced testing technologies to analyze the chemical, physical, and mechanical properties of equipment components.

Q What types of equipment can be tested?

A We test a wide range of equipment, including machinery, engines, gears, bearings, and other industrial components.

Q How often should I have my equipment tested?

A Regular testing is recommended to ensure optimal equipment performance. The frequency of testing depends on the type of equipment, usage patterns, and industry standards.

Q Can I trust the results from Eurolabs testing services?

A Yes. Our team of expert technicians adheres to strict quality control measures, ensuring that all test results are accurate and reliable.

Conclusion

In todays competitive industrial landscape, companies like Eurolab play a vital role in helping businesses maintain efficiency and minimize losses caused by equipment failure. By leveraging our testing services for errors introduced by mechanical wear or component degradation, organizations can take proactive steps to prevent unexpected failures, reduce downtime, and optimize maintenance schedules.

By choosing Eurolabs laboratory service, youre investing in the long-term success of your business. Dont wait until its too late contact us today to learn more about how our testing services can benefit your organization.

Related Services

At Eurolab, we offer a comprehensive range of laboratory services designed to support businesses in maintaining optimal equipment performance and preventing unexpected failures. Our services include

Material Analysis

Failure Analysis

Corrosion Testing

Mechanical Properties Testing

Discover how our laboratory services can help your business thrive visit our website to learn more about our offerings and expertise.

Get Started Today

Dont let equipment failure hold you back from achieving your goals. Contact Eurolab today to discuss your testing needs and schedule an appointment with one of our expert technicians.

By partnering with us, youll gain access to

Expert advice on optimizing maintenance schedules

Regular equipment assessments to identify potential issues before they become major problems

Customized testing solutions tailored to meet the unique requirements of your business

Choose Eurolab for your laboratory needs and experience the benefits of our expertise firsthand.