Testing for Harmonics and Overtones in Frequency Range

Testing for Harmonics and Overtones in Frequency Range Unlocking the Power of Your Business with Eurolab

In todays fast-paced business landscape, ensuring the quality and reliability of your products is crucial to staying ahead of the competition. One often-overlooked aspect of product testing is the analysis of harmonics and overtones within a specific frequency range. Harmonics and overtones can have a significant impact on the performance and lifespan of equipment, as well as contribute to noise pollution and electromagnetic interference (EMI). At Eurolab, we offer comprehensive laboratory services for Testing for Harmonics and Overtones in Frequency Range, empowering businesses like yours to optimize their products and stay compliant with industry regulations.

What is Testing for Harmonics and Overtones in Frequency Range?

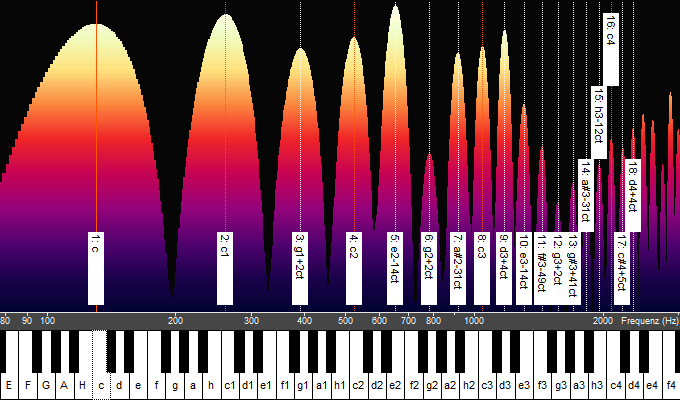

Testing for harmonics and overtones involves analyzing the frequency range of a device or system to identify any unwanted frequency components that may be present. These unwanted frequencies can arise from various sources, including electrical devices, mechanical equipment, and even human-made noise pollution. The analysis of these harmonics and overtones is critical in determining their impact on the overall performance and efficiency of your product.

The Importance of Harmonic Analysis

Harmonic analysis has become increasingly important in recent years due to the growing awareness of electromagnetic compatibility (EMC) and radio-frequency interference (RFI). Modern products must adhere to strict standards for harmonic emissions, which can be challenging to achieve without proper testing. Failure to comply with these regulations can result in costly fines, product recalls, and damage to your companys reputation.

Advantages of Using Testing for Harmonics and Overtones in Frequency Range

Eurolabs comprehensive laboratory services offer numerous advantages for businesses seeking to optimize their products. Some key benefits include

Improved Product Performance By identifying and mitigating unwanted frequency components, you can enhance the overall performance and efficiency of your product.

Reduced Interference Harmonic analysis helps minimize electromagnetic interference (EMI) and radio-frequency interference (RFI), ensuring that your product operates seamlessly in various environments.

Compliance with Regulations Our laboratory services ensure compliance with industry standards for harmonic emissions, reducing the risk of fines and product recalls.

Cost Savings By identifying and addressing harmonics and overtones early on, you can avoid costly redesigns and rework, saving time and resources.

Increased Customer Satisfaction By providing high-quality products that meet or exceed regulatory requirements, you can enhance customer satisfaction and loyalty.

Key Benefits of Harmonic Analysis

Some key benefits of harmonic analysis include

Enhanced Efficiency Reduces energy consumption and increases overall system efficiency

Improved Safety Minimizes the risk of electromagnetic interference (EMI) and radio-frequency interference (RFI)

Increased Reliability Identifies potential issues before they cause equipment failure or downtime

Reduced Maintenance Decreases the need for maintenance and repair, saving time and resources

Comprehensive Testing Capabilities

Eurolabs state-of-the-art laboratory facilities are equipped to handle a wide range of testing services, including

Frequency Range Analysis Identifies unwanted frequency components within a specific frequency range

Harmonic Emission Measurement Measures the level of harmonic emissions from your product

EMC Testing Evaluates the electromagnetic compatibility (EMC) of your product

QA Frequently Asked Questions

Q What is the difference between harmonics and overtones?

A Harmonics are integer multiples of a fundamental frequency, while overtones are non-integer multiples that can be either higher or lower in frequency than the fundamental.

Q Why is harmonic analysis important for businesses?

A Harmonic analysis helps ensure compliance with industry regulations, reduces interference, and improves product performance.

Q How do I choose the correct frequency range for testing?

A The frequency range will depend on the specific application and requirements of your product. Consult with our experts to determine the most suitable frequency range for testing.

Q What types of products require harmonic analysis?

A Any product that emits electromagnetic radiation or has a potential impact on electromagnetic compatibility (EMC) may require harmonic analysis, including but not limited to, electrical devices, mechanical equipment, and communication systems.

Conclusion

At Eurolab, we understand the importance of accurate and reliable testing for harmonics and overtones in frequency range. Our comprehensive laboratory services empower businesses like yours to optimize their products, ensure compliance with industry regulations, and reduce interference. By choosing Eurolabs Testing for Harmonics and Overtones in Frequency Range, you can unlock the full potential of your business and stay ahead of the competition.

Dont let unwanted frequency components hold you back trust Eurolab to provide the expertise and facilities needed to ensure the quality and reliability of your products. Contact us today to learn more about our laboratory services and discover how we can help take your business to the next level.