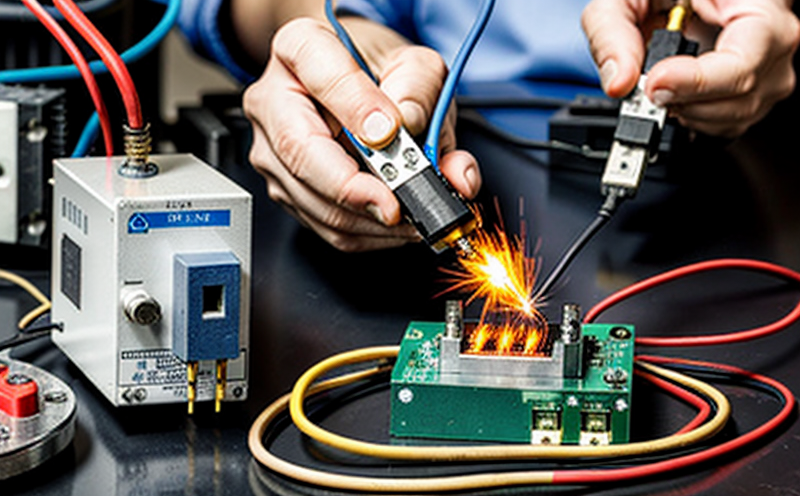

Testing for ignition resistance in electrical components and wiring used in consumer devices

Unlocking Safe and Reliable Electrical Components The Importance of Testing for Ignition Resistance

In todays fast-paced world of consumer electronics, the demand for safe and reliable electrical components is higher than ever. As businesses strive to meet these demands, they must also adhere to strict safety regulations and standards to ensure their products do not pose a fire hazard to consumers. One crucial aspect of ensuring electrical component safety is testing for ignition resistance. In this article, we will delve into the world of Testing for ignition resistance in electrical components and wiring used in consumer devices, exploring its significance, advantages, and the expert services provided by Eurolab.

What is Testing for Ignition Resistance?

Testing for ignition resistance refers to a laboratory analysis that determines an electrical components or wirings ability to resist igniting when exposed to heat, flames, or other forms of thermal stress. This testing is critical in evaluating the safety and performance of electrical components used in various consumer devices, such as appliances, smartphones, laptops, and automotive systems.

Why is Testing for Ignition Resistance Essential?

The importance of testing for ignition resistance cannot be overstated. Electrical fires are a significant concern globally, causing millions of dollars in damages annually and putting countless lives at risk. Moreover, manufacturers face hefty fines and reputational damage when their products fail to meet safety standards. By incorporating ignition resistance testing into their product development process, businesses can

Advantages of Testing for Ignition Resistance

Compliance with Safety Regulations Ensure your electrical components comply with international standards (UL, IEC, EN) and national regulations.

Reduced Liability Minimize the risk of electrical fires and associated damages by testing for ignition resistance in your components.

Enhanced Product Reliability Identify potential ignition risks early on and design products that are safer and more reliable.

Improved Customer Trust Gain confidence among consumers by demonstrating a commitment to safety and quality.

Cost Savings Avoid costly product recalls, rework, or litigation by testing for ignition resistance during the development stage.

Benefits of Partnering with Eurolab

At Eurolab, our expert team provides comprehensive Testing for ignition resistance in electrical components and wiring used in consumer devices. Our state-of-the-art laboratory facilities and cutting-edge technology enable us to offer

Accurate Results Obtain precise and reliable test results from our experienced technicians.

Rapid Turnaround Expedited testing services ensure you can meet tight deadlines without compromising quality.

Customized Solutions Tailor-made testing programs tailored to your products specific requirements.

Expert Consultation Collaborate with our seasoned professionals to optimize your product development process.

QA Frequently Asked Questions about Testing for Ignition Resistance

Q1 What types of electrical components require ignition resistance testing?

A1 All electrical components and wiring used in consumer devices, including appliances, electronics, automotive systems, and more.

Q2 How is the ignition resistance test performed?

A2 Our expert technicians use specialized equipment to expose the electrical component or wiring to controlled heat sources (e.g., flame or hot plate) while monitoring its behavior under different conditions.

Q3 What standards do you follow for Testing for ignition resistance?

A3 We adhere to international standards (UL, IEC, EN) and national regulations to ensure our testing services meet the highest industry benchmarks.

Q4 Can I request customized testing programs or protocols?

A4 Yes! Our experienced team will work closely with you to develop a tailored testing plan that meets your specific needs and product requirements.

Conclusion

Testing for ignition resistance in electrical components and wiring used in consumer devices is an essential step in ensuring the safety, performance, and reliability of products. At Eurolab, our commitment to excellence and safety has earned us a reputation as industry leaders in this field. Partner with us today and unlock the benefits of comprehensive Testing for ignition resistance services.

By choosing Eurolabs expert laboratory services, you can

Enhance product safety and compliance

Reduce liability and associated costs

Improve customer trust and confidence

Stay ahead of regulatory requirements

Dont let electrical fires compromise your business. Trust Eurolab to provide the testing expertise you need to safeguard your products and customers.

-

Testing the resistance of consumer products to catching fire under various conditions

-

Evaluating the combustibility of materials used in products like textiles, plastics, and electronics

-

Simulating exposure to flames or heat to assess how products perform during fire-related incidents

-

Assessing the effectiveness of flame-retardant materials used in consumer goods such as clothing and furniture

-

Testing for ignition resistance in consumer products like children's toys, electronics, or appliances

-

Verifying the flammability of packaging materials and ensuring they meet fire safety standards

-

Testing the fire-resistance of components used in consumer goods exposed to high heat or direct flames

-

Assessing the performance of fire safety measures, such as fireproof coatings or self-extinguishing materials

-

Simulating common household fire scenarios to evaluate product behavior in emergency conditions

-

Testing the burn time, spread, and temperature rise of products exposed to fire

-

Evaluating the release of toxic fumes or gases from materials used in consumer products when ignited

-

Testing for the effectiveness of fire alarms or suppression systems integrated into consumer products

-

Simulating prolonged exposure to heat sources to assess the long-term fire risk of products

-

Assessing whether products are designed to minimize flammability risks during transport or use

-

Testing for flame resistance in everyday products, such as mattresses, curtains, or carpets

-

Verifying compliance with fire safety regulations and certifications for consumer goods

-

Assessing the potential for sparks or fires from malfunctioning electrical parts in consumer products

-

Evaluating the durability of flame-resistant treatments under wear, washing, and environmental conditions

-

Simulating the behavior of materials in diverse fire scenarios to assess real-world flammability risks

-

Ensuring that products with high fire risks have appropriate safety labels and warnings