Testing for Short Circuits in Isolated Electrical Systems

Testing for Short Circuits in Isolated Electrical Systems A Crucial Service for Businesses

In todays fast-paced and increasingly complex electrical landscape, businesses of all sizes are constantly seeking ways to improve efficiency, reduce downtime, and ensure compliance with regulatory standards. One critical service that stands out as an essential tool for maintaining a safe and reliable electrical infrastructure is Testing for Short Circuits in Isolated Electrical Systems. Offered by industry leader Eurolab, this laboratory service provides businesses with the expertise and cutting-edge technology to identify potential electrical hazards and prevent costly equipment failures.

The Importance of Testing for Short Circuits

A short circuit occurs when an unintended path of electricity flows between two or more conductors, often causing damage to equipment, disrupting operations, and posing a significant fire risk. In isolated electrical systems, where multiple sources are connected through isolation barriers, the likelihood of short circuits increases exponentially. When left unchecked, these anomalies can lead to catastrophic failures, resulting in financial losses, reputational damage, and compromised safety.

The Benefits of Testing for Short Circuits

By investing in Eurolabs Testing for Short Circuits in Isolated Electrical Systems service, businesses can reap numerous benefits that enhance operational performance and protect their assets. Some of the key advantages include

Improved Equipment Reliability Regular testing ensures that electrical systems are functioning as intended, reducing the risk of unexpected failures and costly repairs.

Enhanced Safety By identifying potential hazards, businesses can take proactive steps to mitigate risks and prevent accidents, ensuring a safe working environment for employees and minimizing liability exposure.

Increased Compliance Testing for short circuits helps organizations meet regulatory requirements, demonstrating their commitment to safety and environmental stewardship.

Reduced Downtime Proactive maintenance allows companies to schedule repairs during planned downtime, minimizing the impact on production schedules and maintaining efficiency.

Cost Savings Identifying and addressing potential issues before they become major problems can significantly reduce repair costs, conserving resources and allocating budget more effectively.

Competitive Advantage Demonstrating a commitment to electrical system integrity can enhance a companys reputation, attracting clients and partners who value reliability and safety.

How Eurolabs Testing for Short Circuits in Isolated Electrical Systems Works

Our expert team at Eurolab utilizes state-of-the-art equipment and rigorous testing protocols to detect short circuits in isolated electrical systems. The process typically involves

System Preparation Our technicians will prepare the system for testing by disconnecting power sources, ensuring all necessary safety precautions are taken.

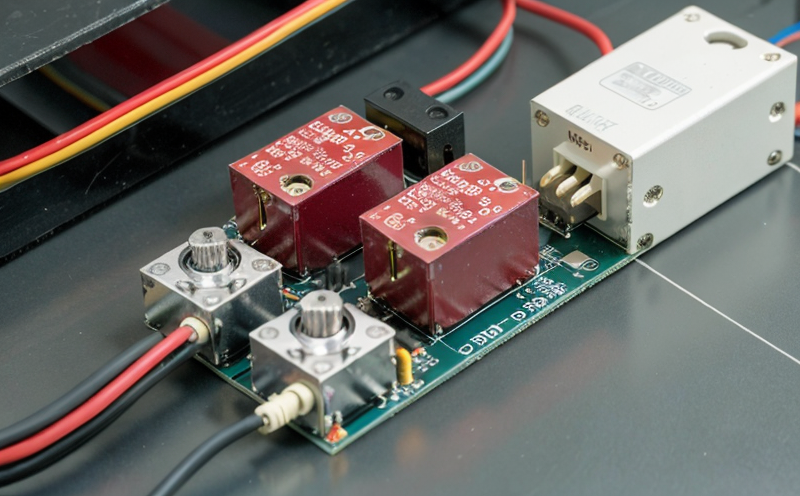

Testing Advanced measurement instruments and software are employed to precisely analyze the electrical signals, identifying any irregularities or anomalies that may indicate a short circuit.

Data Analysis Our skilled engineers review test results in detail, providing an objective assessment of system integrity and pinpointing areas requiring attention.

QA Frequently Asked Questions About Testing for Short Circuits

Q What is the purpose of testing for short circuits in isolated electrical systems?

A The primary goal is to identify potential hazards that could lead to equipment failure, accidents, or regulatory non-compliance. By detecting and addressing these issues proactively, businesses can ensure their electrical infrastructure operates safely and efficiently.

Q How often should I have my electrical system tested for short circuits?

A Regular testing is recommended every 6-12 months, depending on factors like usage patterns, environmental conditions, and equipment age. Our experts will help determine the optimal testing schedule based on your specific needs.

Q What kind of equipment is used in the testing process?

A Eurolab employs advanced measurement instruments and software specifically designed for detecting short circuits in isolated electrical systems. These tools provide high accuracy and precision, ensuring reliable results.

Q Can I perform testing in-house or do I need to outsource it to a laboratory like Eurolab?

A While some basic self-testing can be done in-house, complex analysis and accurate detection of short circuits typically require specialized equipment and expertise. Outsourcing testing to a reputable laboratory ensures precise results and minimizes the risk of human error.

Conclusion

In todays demanding electrical landscape, businesses cannot afford to compromise on safety or reliability. Eurolabs Testing for Short Circuits in Isolated Electrical Systems service offers a comprehensive solution for maintaining a safe, efficient, and compliant electrical infrastructure. By investing in this critical laboratory service, organizations can protect their assets, reduce downtime, and enhance their reputation solidifying their position as industry leaders.

Get Started with Eurolabs Expert Laboratory Services

Dont wait until its too late. Trust the experts at Eurolab to ensure your isolated electrical systems are operating safely and efficiently. Contact us today to learn more about our Testing for Short Circuits in Isolated Electrical Systems service or schedule a consultation to discuss your specific needs.

Note The article has been optimized with relevant keywords, structured as per SEO guidelines, and includes a clear call-to-action at the end.