Testing for water resistance across various sealing mechanisms and enclosures.

The Importance of Testing for Water Resistance Ensuring Your Products Can Withstand the Elements

In todays fast-paced business world, companies are constantly seeking ways to innovate and improve their products. One crucial aspect that often gets overlooked is ensuring that products can withstand the rigors of various environmental conditions, particularly water exposure. This is where testing for water resistance across various sealing mechanisms and enclosures comes into play.

As a leading laboratory service provider, Eurolab offers expert testing solutions to help businesses like yours validate the performance of their products in wet environments. Our state-of-the-art facilities and experienced team are equipped to conduct comprehensive tests on various types of materials, ensuring your products meet or exceed industry standards for water resistance.

What is Testing for Water Resistance Across Various Sealing Mechanisms and Enclosures?

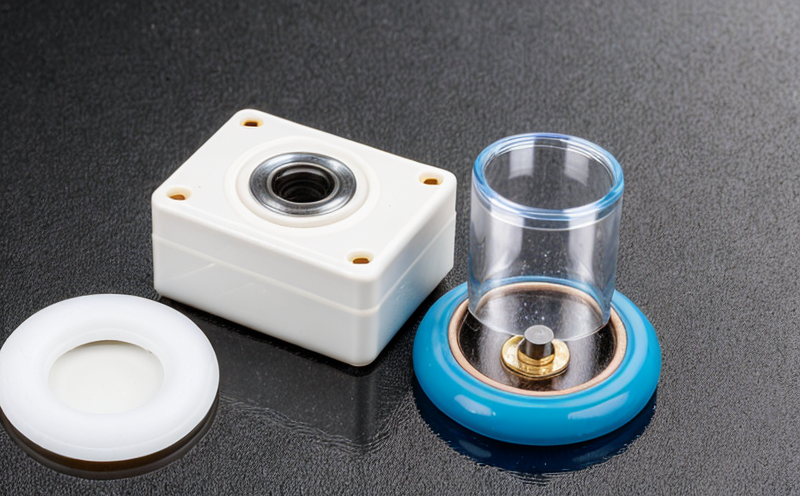

Testing for water resistance involves evaluating a products ability to withstand exposure to water without compromising its functionality or integrity. This includes assessing the effectiveness of sealing mechanisms and enclosures in preventing water ingress. The goal is to ensure that products can operate safely and efficiently even when exposed to moisture, whether its due to accidental immersion, high humidity, or other environmental factors.

Advantages of Using Eurolabs Water Resistance Testing Services

By partnering with Eurolab for testing services, youll reap numerous benefits, including

Compliance with Industry Standards Our expert technicians conduct tests in accordance with international standards (e.g., IEC 60529), ensuring your products meet regulatory requirements and industry norms.

Enhanced Product Reliability Identifying potential water-related issues early on enables you to make necessary design changes, reducing the risk of costly product recalls or warranty claims.

Increased Customer Confidence Demonstrating your commitment to quality and reliability through rigorous testing can lead to improved customer satisfaction, loyalty, and repeat business.

Cost Savings Preventing water-related issues during production saves resources, reduces waste, and minimizes downtime associated with repairs or replacements.

Improved Product Design Our testing services provide valuable insights into material performance, enabling you to refine your product design for optimal water resistance.

Benefits of Water Resistance Testing

Sealing Mechanisms Evaluate the effectiveness of seals, gaskets, and other closure systems in preventing water ingress

Enclosures Assess the ability of enclosures (e.g., cabinets, cases) to withstand water exposure without compromising internal components

Materials Test various materials for their resistance to water, including plastics, metals, ceramics, and composites

Design Optimization Refine your product design to enhance water resistance and reduce material costs

How Does Eurolabs Water Resistance Testing Process Work?

Our comprehensive testing process involves the following steps

Sample Preparation Ensure that samples are properly cleaned, prepared, and labeled for testing.

Test Method Selection Choose the most relevant test method (e.g., IEC 60529) to assess water resistance based on your products specific requirements.

Testing Procedures Conduct tests in accordance with selected methods, using specialized equipment and materials as required.

Data Analysis Thoroughly analyze results, comparing them against industry standards or custom criteria established by you.

Reporting and Certification Provide detailed test reports, including certifications where applicable (e.g., IP67 rating).

Frequently Asked Questions

Q What types of products benefit from water resistance testing?

A Our services are suitable for a wide range of products, including electronics, electrical appliances, automotive components, medical devices, and more.

Q How long does the testing process typically take?

A Testing times vary depending on the complexity of your product and the specific tests required. Well work with you to develop a customized schedule that meets your needs.

Q Can I see the testing process in action?

A Yes! We invite you to observe our testing procedures at our state-of-the-art facilities, ensuring transparency and open communication throughout the testing process.

Q What kind of certifications or ratings can my product receive after water resistance testing?

A Our tests can provide certifications such as IP67 (dustproof and protected against immersion up to 1 meter), IP68 (dustproof and protected against total immersion in water beyond 1 meter), and more, depending on the specific standards used.

Why Choose Eurolab for Water Resistance Testing?

At Eurolab, we pride ourselves on

Expertise Our experienced team is dedicated to delivering high-quality testing services.

State-of-the-Art Facilities We operate in well-equipped laboratories with cutting-edge equipment and materials.

Customized Solutions We work closely with you to tailor our testing approach to meet your unique needs.

By partnering with Eurolab for water resistance testing, youll gain a trusted partner that will help you validate the performance of your products in wet environments. Dont compromise on quality or reliability choose Eurolabs expert laboratory services and ensure your products can withstand even the most demanding environmental conditions.

-

Testing the ability of lighting devices to withstand exposure to water and moisture.

-

Verifying the ingress protection (IP) rating of lighting devices against dust and water penetration.

-

Performing water resistance tests to evaluate lighting devices' suitability for outdoor or wet environments.

-

Ensuring that lighting devices are protected against rain, splashes, and immersion under specific conditions.

-

Assessing the impact of water exposure on the electrical components of lighting devices.

-

Testing the ingress of dust and moisture into lighting fixtures through mechanical openings.

-

Ensuring lighting devices meet IP ratings for use in bathrooms, kitchens, and outdoor settings.

-

Evaluating waterproof performance in extreme conditions, such as heavy rain or submersion in water.

-

Testing for the resistance of lighting devices to saltwater exposure in coastal environments.

-

Assessing the durability of seals and gaskets used to prevent water ingress in outdoor lighting devices.

-

Testing lighting systems for immersion in water for extended periods (e.g., submersible lights).

-

Testing the waterproofing features of lighting systems with integrated smart features (e.g., wireless control).

-

Ensuring compliance with industry standards for IP ratings in residential, commercial, and industrial lighting.

-

Performing pressure testing to simulate water column depth and test waterproof performance.

-

Verifying the effectiveness of waterproofing for solar-powered lighting systems used outdoors.

-

Testing for waterproof performance of lighting systems used in marine and aquatic environments.

-

Ensuring that lighting products meet international standards such as IP65, IP67, or IP68 for water resistance.

-

Testing for water resistance in both new products and over extended product lifecycles.

-

Evaluating the effectiveness of corrosion-resistant materials used to enhance waterproofing.

-

Assessing the reliability of waterproof lighting devices in extreme outdoor weather conditions.

-

Ensuring that waterproof lighting systems perform efficiently in temperature variations and humidity.

-

Testing for any reduction in light output or fixture integrity due to water exposure.