Testing heat seal strength for packaging in refrigerated food

The Importance of Testing Heat Seal Strength for Packaging in Refrigerated Food A Crucial Service Provided by Eurolab

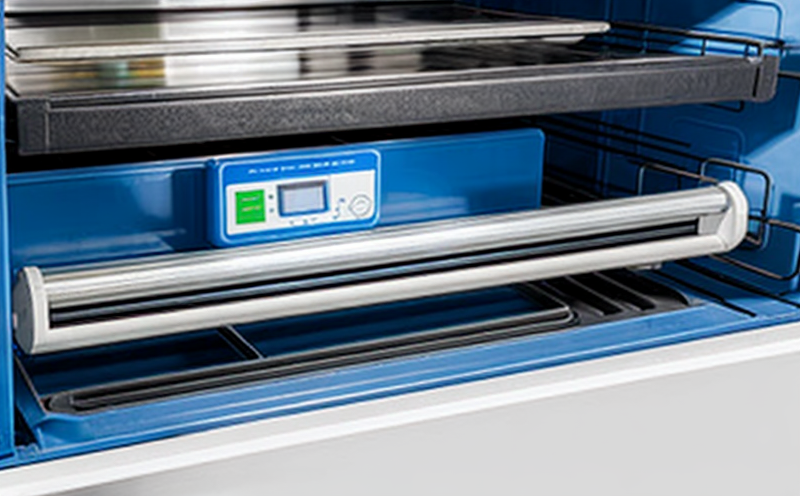

In the food packaging industry, ensuring the integrity and safety of products is paramount. One crucial aspect that often goes unnoticed is the heat seal strength of packaging materials used for refrigerated foods. This critical parameter can significantly impact the quality, shelf life, and overall customer satisfaction of your products. As a leading provider of laboratory services, Eurolab offers Testing heat seal strength for packaging in refrigerated food, a vital service that helps businesses like yours guarantee the reliability of their packaging solutions.

What is Heat Seal Strength?

Heat seal strength refers to the ability of a material or package to withstand high temperatures without compromising its structural integrity. In the context of refrigerated foods, this means evaluating whether the heat-sealed packaging can maintain its shape and prevent leakage or spoilage even when exposed to extreme temperature fluctuations.

Why is Testing Heat Seal Strength Essential for Businesses?

The significance of testing heat seal strength cannot be overstated, especially in the refrigerated food industry. Here are some compelling reasons why this service is vital

Ensures Product Safety By verifying the heat seal strength of packaging materials, businesses can guarantee that their products remain safe and secure throughout the supply chain.

Prevents Economic Losses Inadequate packaging can lead to product spoilage, contamination, or leakage, resulting in significant economic losses for companies. Eurolabs testing services help minimize such risks.

Maintains Brand Reputation Satisfied customers are more likely to return and recommend your products, which contributes to a positive brand image and reputation.

Benefits of Testing Heat Seal Strength

Eurolabs Testing heat seal strength for packaging in refrigerated food service offers numerous benefits to businesses

Improved Product Quality

Enhanced Customer Satisfaction

Reduced Packaging Costs

Increased Efficiency

Compliance with Industry Regulations

Key Benefits of Working with Eurolab

Our comprehensive testing services, combined with our expertise and state-of-the-art equipment, ensure that your packaging solutions meet the highest standards. By partnering with us, you can

Gain Peace of Mind Know that your products are safe and secure.

Stay Ahead of Competition Distinguish yourself through superior quality and reliability.

Enhance Your Brand Reputation Build trust with customers by demonstrating a commitment to product safety.

Frequently Asked Questions

Q What types of packaging materials can be tested?

A Eurolabs services cater to various packaging materials, including films, laminates, and paper-based products used in refrigerated food applications.

Q How do I prepare my samples for testing?

A Please follow our sample preparation guidelines carefully to ensure accurate and reliable results.

Q What is the typical turnaround time for test results?

A Eurolab strives to provide prompt results while maintaining the highest standards of accuracy. Turnaround times may vary depending on the complexity of the tests.

Conclusion

In conclusion, Testing heat seal strength for packaging in refrigerated food is a crucial service that Eurolab provides to businesses in the food packaging industry. By understanding the importance of this parameter and leveraging our expertise, you can ensure the safety, quality, and reliability of your products. Dont compromise on the integrity of your packaging solutions trust Eurolabs comprehensive testing services to guarantee the best possible outcomes for your business.