Testing HVAC Components for Corrosion Under Extreme Humidity

Testing HVAC Components for Corrosion Under Extreme Humidity A Crucial Service for Businesses

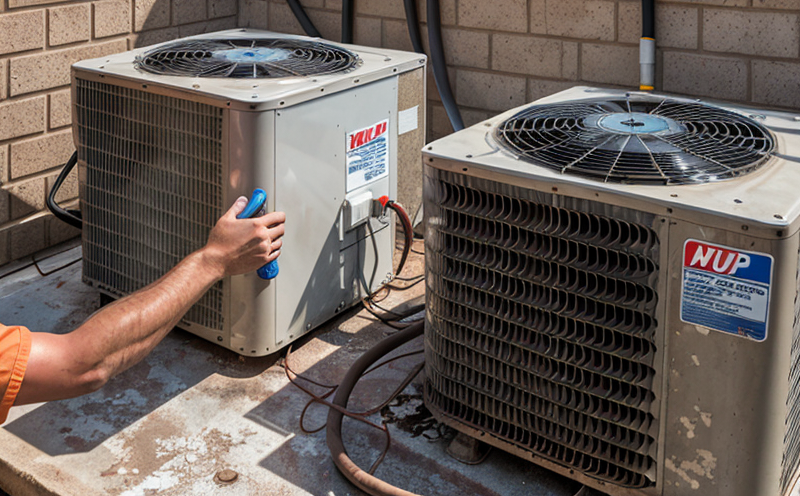

As a business owner in the heating, ventilation, and air conditioning (HVAC) industry, you understand the importance of ensuring your equipment operates efficiently and effectively to maintain a comfortable indoor environment while keeping energy costs under control. However, exposure to extreme humidity can have devastating effects on HVAC components, leading to corrosion that compromises system performance and longevity.

In this article, well delve into the significance of testing HVAC components for corrosion under extreme humidity and explore how our laboratory service at Eurolab can help you mitigate these risks.

What is Testing HVAC Components for Corrosion Under Extreme Humidity?

Testing HVAC components for corrosion under extreme humidity involves subjecting your equipment to simulated conditions that mimic real-world environments, typically in a controlled laboratory setting. Our expert technicians at Eurolab use specialized equipment and procedures to assess the susceptibility of your HVAC components to corrosion when exposed to high levels of humidity.

This testing service is essential because it helps identify potential vulnerabilities before they cause damage or failure, allowing you to take proactive measures to prevent costly repairs, downtime, and reputational harm. By understanding how your equipment will perform under extreme conditions, you can make informed decisions about maintenance, replacement, and upgrades, ultimately reducing the likelihood of unexpected disruptions.

Why is Testing HVAC Components for Corrosion Under Extreme Humidity Important?

Here are some compelling reasons why testing HVAC components for corrosion under extreme humidity is crucial for businesses

Prevents Unexpected Downtime Regular testing helps you identify potential issues before they cause equipment failure, ensuring your systems remain operational even in harsh environments.

Extends Equipment Life By understanding the effects of corrosion on your components, you can take proactive measures to extend their lifespan and minimize maintenance costs.

Enhances System Reliability Testing ensures that your HVAC system operates as intended, providing consistent performance and maintaining a comfortable indoor environment for occupants.

Reduces Energy Consumption Efficient equipment operation means lower energy bills and reduced environmental impact, contributing to a more sustainable future.

Key Benefits of Testing HVAC Components for Corrosion Under Extreme Humidity

Here are the key benefits you can expect from testing your HVAC components with Eurolab

Identifies Potential Vulnerabilities Our laboratory service simulates extreme humidity conditions to assess the susceptibility of your equipment to corrosion.

Enhances System Performance By understanding how your components perform under stress, you can optimize system operation and maintain peak performance.

Minimizes Maintenance Costs Regular testing helps prevent unexpected repairs and reduces maintenance expenses over time.

Supports Regulatory Compliance Our testing services ensure that your equipment meets industry standards and regulations, reducing the risk of non-compliance.

Frequently Asked Questions (FAQs)

Q What types of HVAC components can be tested for corrosion under extreme humidity?

A We test a wide range of components, including coils, fans, compressors, condensers, and more. Our laboratory is equipped to simulate various conditions to assess the impact on different materials and designs.

Q How do I prepare my equipment for testing?

A Before sending your equipment to Eurolab, ensure its properly cleaned and prepared according to our guidelines. This will help us perform accurate tests and provide reliable results.

Q What kind of reports and recommendations can I expect from the testing process?

A Our expert technicians will provide detailed test reports, highlighting potential vulnerabilities and offering actionable recommendations for improving equipment performance and extending lifespan.

Q Can I request specific testing protocols or customize the testing procedure to suit my needs?

A Absolutely. We work closely with our clients to tailor the testing process to their unique requirements, ensuring that we simulate conditions relevant to their specific environment and system configuration.

Why Choose Eurolab for Testing HVAC Components?

At Eurolab, we understand the complexities of testing HVAC components under extreme humidity conditions. Our laboratory is equipped with state-of-the-art equipment, and our expert technicians are dedicated to providing accurate results and actionable recommendations. By partnering with us, you can

Ensure Equipment Reliability Trust in our expertise to test your equipment thoroughly, identifying potential vulnerabilities and areas for improvement.

Minimize Downtime With regular testing, youll be prepared for unexpected disruptions, ensuring that your systems remain operational even in the most challenging environments.

Stay Compliant Our laboratory services ensure that your equipment meets industry standards and regulations, reducing the risk of non-compliance.

By understanding the importance of testing HVAC components for corrosion under extreme humidity and partnering with a trusted laboratory service like Eurolab, you can safeguard your business against potential risks and maintain a competitive edge in the industry. Contact us today to learn more about our comprehensive laboratory services and take the first step toward optimizing your equipment performance.