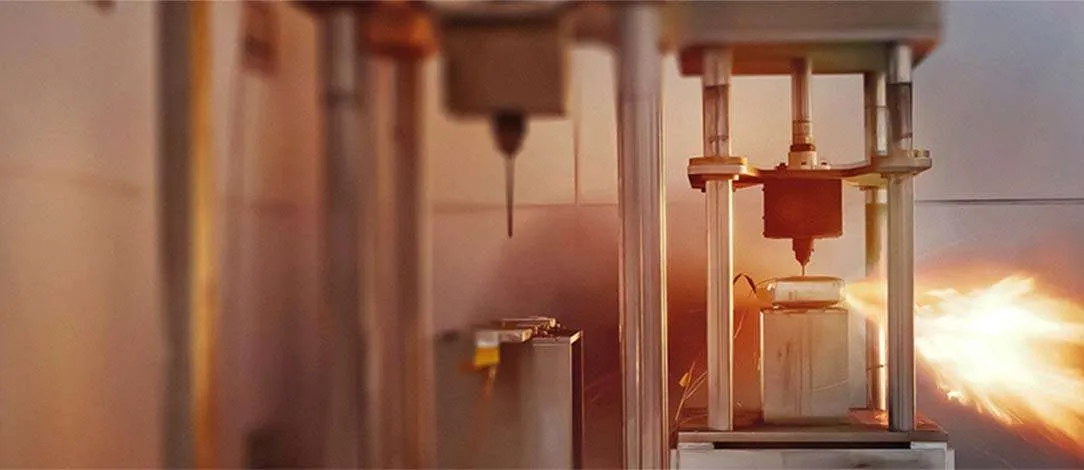

Testing nail penetration in batteries used for medical applications

Testing Nail Penetration in Batteries Used for Medical Applications Ensuring Safety and Compliance

As the demand for medical devices and equipment continues to rise, manufacturers are under increasing pressure to ensure that their products meet rigorous safety standards. One critical aspect of this process is testing nail penetration in batteries used for medical applications. In this article, well delve into the importance of this laboratory service, provided by Eurolab, and explore its benefits for businesses operating in the medical industry.

What is Testing Nail Penetration in Batteries Used for Medical Applications?

Testing nail penetration in batteries used for medical applications involves assessing a batterys ability to withstand a puncture from a sharp object, such as a nail. This test simulates a worst-case scenario, where a patient or caregiver accidentally pierces the battery casing with a sharp object. The goal is to determine whether the battery can contain the short circuit and prevent electrical shock, fire, or other hazards.

Why is Testing Nail Penetration in Batteries Used for Medical Applications Essential?

In medical devices and equipment, batteries are often designed to be compact and lightweight, making them more susceptible to damage from accidental punctures. A single incident of nail penetration can have catastrophic consequences, including patient harm, device failure, or even fatalities.

Regulatory bodies, such as the FDA (Food and Drug Administration) in the United States and ISO 10993 in Europe, require medical device manufacturers to demonstrate compliance with strict safety standards, including those related to battery performance. Testing nail penetration is a critical component of this process, ensuring that batteries used in medical applications meet or exceed these stringent requirements.

Advantages of Using Eurolabs Testing Nail Penetration Service

By choosing Eurolab for your testing needs, you can benefit from

Compliance with Regulatory Requirements Our experts will guide you through the complex regulatory landscape, ensuring that your products meet the necessary standards and comply with international regulations.

Enhanced Product Safety By identifying potential vulnerabilities in battery design, we help prevent accidents and ensure patient safety.

Reduced Liability With Eurolabs testing services, you can demonstrate due diligence and reduce liability associated with product failure or malfunction.

Improved Manufacturing Efficiency Our testing and evaluation process helps identify areas for improvement in manufacturing processes, streamlining production and reducing costs.

Key Benefits of Testing Nail Penetration

Here are some key benefits of incorporating nail penetration testing into your quality control process

Prevents Electrical Shock and Fire Hazards By ensuring that batteries can contain short circuits, you protect patients from electrical shock or fire.

Minimizes Product Returns and Liability Regular testing helps identify design flaws early on, reducing the risk of product recalls and associated costs.

Improves Patient Safety By guaranteeing battery performance under worst-case scenarios, you ensure a safe and reliable medical device.

Enhances Brand Reputation Compliance with regulatory requirements demonstrates your commitment to quality and safety, boosting customer trust and loyalty.

Frequently Asked Questions (FAQs)

Q What types of batteries can be tested for nail penetration?

A Eurolabs testing services cover a wide range of battery types used in medical applications, including lithium-ion, nickel-cadmium, and lead-acid batteries.

Q How do I prepare my samples for testing?

A Our expert team will guide you through the sampling process to ensure that your products are prepared according to our testing protocols.

Q What is the typical turnaround time for testing results?

A Eurolabs state-of-the-art facilities and experienced staff enable us to provide fast and reliable test results, typically within 2-3 weeks.

Q Can I get a certificate of compliance with regulatory requirements after testing?

A Yes, we issue certificates of compliance that meet international standards (e.g., ISO 10993), ensuring your products meet regulatory requirements.

Conclusion

In the medical industry, safety and compliance are paramount. Testing nail penetration in batteries used for medical applications is an essential component of this process, ensuring that patients and caregivers are protected from potential hazards. By partnering with Eurolab, manufacturers can guarantee their products meet stringent safety standards, reducing liability and improving brand reputation.

Dont compromise on patient safety choose Eurolabs expert testing services to ensure your batteries meet the highest standards of performance and reliability.