Testing of yield strength in materials with low ductility

Unveiling the Crucial Role of Yield Strength Testing in Materials with Low Ductility A Game-Changer for Businesses

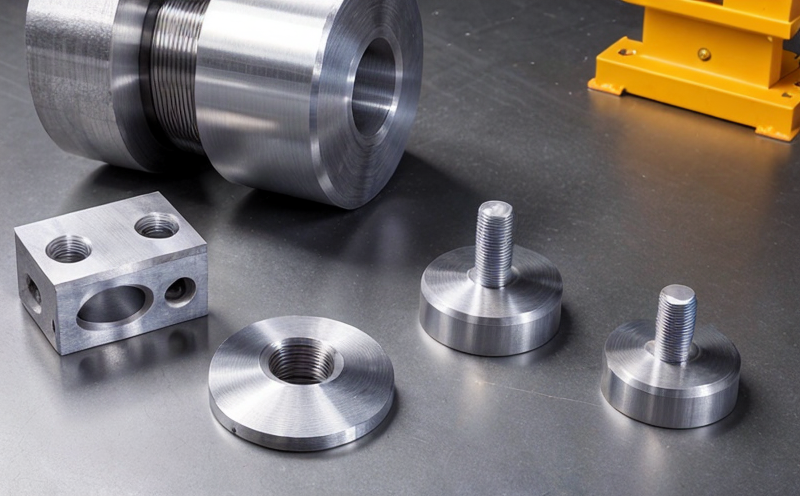

In todays fast-paced manufacturing industry, materials play a pivotal role in determining the success or failure of products and processes. Among various material properties, yield strength stands out as a critical parameter that significantly influences the performance, reliability, and durability of components. However, testing yield strength in materials with low ductility poses significant challenges due to their brittle nature. This is where Eurolab comes into play a leading laboratory service provider specializing in testing yield strength in materials with low ductility.

The Importance of Yield Strength Testing

Yield strength is the minimum stress required to initiate plastic deformation in a material, beyond which it begins to deform plastically under constant load. Materials with low ductility exhibit reduced ability to absorb energy and withstand stress without failing catastrophically. Consequently, accurate determination of yield strength becomes crucial for ensuring product safety, reliability, and performance.

In industries such as aerospace, automotive, construction, and oil gas, the use of materials with low ductility is common due to their unique properties. However, these materials often require specialized testing methods to accurately determine their yield strength. Eurolabs state-of-the-art laboratory facilities and expert technicians are equipped to handle such delicate tasks.

Benefits of Testing Yield Strength in Materials with Low Ductility

By investing in yield strength testing services from Eurolab, businesses can reap numerous benefits that translate into enhanced product performance, improved safety records, and increased competitiveness

Prevents Catastrophic Failures Accurate determination of yield strength helps prevent material failure under stress, reducing the risk of costly equipment damage, production downtime, and potential harm to personnel.

Ensures Product Reliability By understanding a materials yield strength, manufacturers can optimize product design, ensure consistent performance, and meet or exceed regulatory standards.

Optimizes Material Selection Eurolabs testing services enable businesses to select materials that meet specific application requirements, reducing the risk of material failure due to inadequate selection.

Enhances Safety Records By identifying potential risks associated with low ductility materials, companies can develop strategies to mitigate these risks, improving overall safety performance and regulatory compliance.

Reduces Energy Consumption Yield strength testing helps manufacturers optimize material usage, reduce waste, and minimize energy consumption a critical factor in reducing environmental impact.

The Challenges of Testing Low Ductility Materials

Materials with low ductility are notoriously difficult to test due to their brittle nature. Conventional testing methods may result in inaccurate or unreliable data, leading to incorrect conclusions about the materials yield strength. Eurolabs expert technicians employ specialized techniques and equipment designed specifically for testing these materials

High-Sensitivity Testing Equipment Our state-of-the-art machines provide precise measurements of yield strength, even at low ductility levels.

Expertise in Material Behavior Eurolabs technical team has extensive experience with materials that exhibit low ductility, ensuring accurate interpretation of test results.

Tailored Test Programs We develop customized testing protocols to suit specific material requirements and application needs.

QA Frequently Asked Questions

Q What is the difference between yield strength and tensile strength?

A Yield strength represents the minimum stress required for plastic deformation, while tensile strength represents the maximum stress a material can withstand before failure. In materials with low ductility, yield strength becomes a critical parameter.

Q How do you test materials with low ductility at Eurolab?

A Our expert technicians employ specialized testing equipment and techniques designed to handle brittle materials without causing premature failure or inaccurate results.

Q Can I conduct yield strength tests in-house, or is it essential to outsource to a laboratory like Eurolab?

A While some companies may have the necessary equipment and expertise for basic testing, materials with low ductility require specialized knowledge and advanced equipment. Outsourcing to a reputable laboratory like Eurolab ensures accurate results and minimizes risk.

Q What if Im unsure about the materials properties or application requirements?

A Our expert technicians are available to discuss specific needs and develop tailored test programs that cater to individual requirements.

Conclusion

In todays competitive manufacturing landscape, understanding the yield strength of materials with low ductility is no longer a luxury but an imperative. By partnering with Eurolab for testing services, businesses can ensure product reliability, safety records, and regulatory compliance while optimizing material selection and minimizing energy consumption. Dont compromise on accuracy or risk catastrophic failures entrust your critical testing needs to the experts at Eurolab.