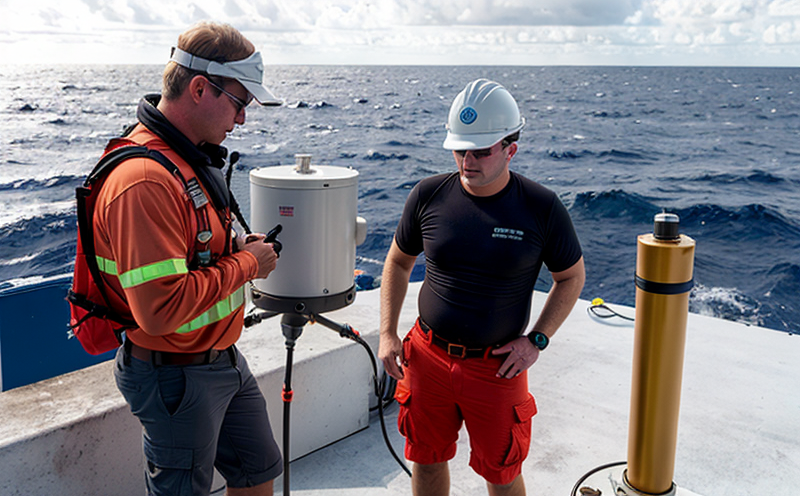

Testing Offshore Sensors for Thermal Shock Performance

Unlocking the Secret to Your Sensors Endurance Testing Offshore Sensors for Thermal Shock Performance

As a manufacturer of offshore sensors, you understand the importance of ensuring that your products can withstand the harsh conditions encountered in marine environments. One critical factor that can significantly impact the lifespan and reliability of your sensors is thermal shock performance. Prolonged exposure to extreme temperature fluctuations can cause damage to even the most robustly designed sensors, leading to reduced functionality, decreased accuracy, and ultimately, costly equipment failures.

Thats where Testing Offshore Sensors for Thermal Shock Performance comes in a specialized laboratory service that simulates real-world temperature cycling conditions to assess your sensors thermal shock performance. Conducted by Eurolab, this rigorous testing protocol allows you to identify potential weaknesses and design vulnerabilities before they become major issues. By partnering with us, you can ensure the reliability and longevity of your offshore sensors, safeguarding your business from financial losses due to equipment failures.

Why Testing Offshore Sensors for Thermal Shock Performance Matters

Thermal shock performance is a critical parameter in determining the overall fitness-for-purpose of your sensor. When exposed to rapid temperature changes, materials can experience thermal stresses that lead to material degradation, fatigue, and eventual failure. This phenomenon is particularly pronounced in marine environments where water temperature fluctuations are more extreme compared to land-based applications.

The consequences of inadequate thermal shock testing can be severe

Reduced sensor lifespan Premature aging due to thermal cycling can shorten the sensors operational life.

Decreased accuracy Temperature-induced stress can affect measurement precision, compromising data quality and integrity.

Increased maintenance costs Repairing or replacing failed sensors can lead to significant expenses and downtime.

The Benefits of Testing Offshore Sensors for Thermal Shock Performance

Eurolabs comprehensive testing protocol offers numerous benefits to businesses like yours

Ensures Sensor Reliability By simulating real-world thermal shock conditions, we help you identify potential design weaknesses and vulnerabilities.

Extends Sensor Lifespan Our testing allows you to refine your sensor designs, reducing the likelihood of premature aging due to thermal cycling.

Improves Accuracy By evaluating your sensors performance under extreme temperature fluctuations, we ensure that measurements remain precise and reliable.

Reduces Maintenance Costs Identifying potential issues before deployment saves you from expensive repairs or replacements.

Enhances Product Quality Our testing helps you adhere to industry standards and regulatory requirements for offshore sensors.

Minimizes Downtime By anticipating equipment failures, you can plan maintenance schedules accordingly, reducing the impact on your operations.

How Testing Offshore Sensors for Thermal Shock Performance Works

Our expert technicians conduct a thorough examination of your sensor design, identifying potential areas of weakness. We then simulate real-world thermal shock conditions using our state-of-the-art testing facilities

Environmental Chamber Our advanced environmental chamber mimics the temperature fluctuations encountered in marine environments.

Temperature Cycling Your sensor is subjected to rapid temperature changes between ambient and extreme temperatures (e.g., -20C to 80C).

Monitoring and Data Analysis We continuously monitor your sensors performance, collecting data on temperature-induced stress, material degradation, and other relevant parameters.

QA Frequently Asked Questions

Q What types of sensors can be tested?

A Our laboratory service is designed for a wide range of offshore sensors, including temperature probes, pressure transmitters, flow meters, and more.

Q How long does the testing process take?

A The duration of our testing protocol varies depending on your specific requirements. Typically, it ranges from several days to several weeks.

Q Can I be present during the testing process?

A Yes, we encourage collaboration with our experts throughout the testing process. We welcome your presence and input in refining your sensor design.

Q Will you provide a comprehensive report of the test results?

A Absolutely! Our detailed report will include an analysis of your sensors thermal shock performance, highlighting areas for improvement and recommendations for refinements.

Conclusion

Testing Offshore Sensors for Thermal Shock Performance is a critical step in ensuring the reliability and accuracy of your equipment. By partnering with Eurolab, you can guarantee the longevity and effectiveness of your offshore sensors. Our comprehensive testing protocol offers numerous benefits, including extended sensor lifespan, improved accuracy, reduced maintenance costs, and enhanced product quality.

Dont let thermal shock performance compromise your business. Contact us today to schedule a testing session and take the first step towards ensuring the integrity of your offshore sensors.