Testing the Durability of Brake Components Under Vibrational Stress

Testing the Durability of Brake Components Under Vibrational Stress Ensuring Road Safety through Reliability

In todays automotive industry, where safety and reliability are paramount, the performance of brake components plays a vital role in preventing accidents and ensuring the well-being of drivers and passengers on the road. However, vehicles are constantly exposed to various environmental factors, including vibrations caused by rough roads, driving styles, and vehicle speed. These vibrations can lead to premature wear and tear of brake components, compromising their effectiveness and potentially resulting in catastrophic consequences.

To mitigate this risk, Eurolab offers a specialized laboratory service Testing the Durability of Brake Components Under Vibrational Stress. This comprehensive testing procedure evaluates the resilience of brake components under simulated vibrational conditions, providing businesses with valuable insights into their products performance and durability.

Why is Testing the Durability of Brake Components Under Vibrational Stress Essential for Businesses?

In a highly competitive market, manufacturers are constantly striving to improve the quality and reliability of their products. By investing in Eurolabs laboratory service, companies can

Enhance road safety By understanding how brake components perform under vibrational stress, manufacturers can identify areas for improvement, ultimately reducing the risk of accidents and ensuring a safer driving experience.

Reduce warranty claims Identifying potential weaknesses in brake component design or manufacturing can help businesses minimize warranty claims and associated costs, improving their bottom line.

Meet regulatory requirements Compliance with industry standards and regulations is crucial. Eurolabs testing service helps companies ensure that their products meet or exceed required standards for durability and performance.

Gain a competitive edge By demonstrating their commitment to quality and safety through rigorous testing, manufacturers can differentiate themselves from competitors and establish trust with customers.

Key Benefits of Testing the Durability of Brake Components Under Vibrational Stress

Our laboratory service provides businesses with the following advantages

Comprehensive testing Our state-of-the-art equipment simulates various vibrational conditions, ensuring that brake components are tested under a range of scenarios.

Customizable testing protocols We work closely with clients to develop tailored testing plans that meet their specific needs and requirements.

Data-driven insights Detailed reports and recommendations provide manufacturers with actionable data to inform design improvements, material selections, or manufacturing process optimizations.

Cost savings By identifying potential weaknesses early on, businesses can avoid costly re-designs, tooling changes, or production halts.

Improved product development Eurolabs testing service accelerates the development cycle by providing manufacturers with valuable data to inform product design and optimization.

Frequently Asked Questions

Weve compiled a list of common questions about Testing the Durability of Brake Components Under Vibrational Stress

Q What types of brake components can be tested under vibrational stress?

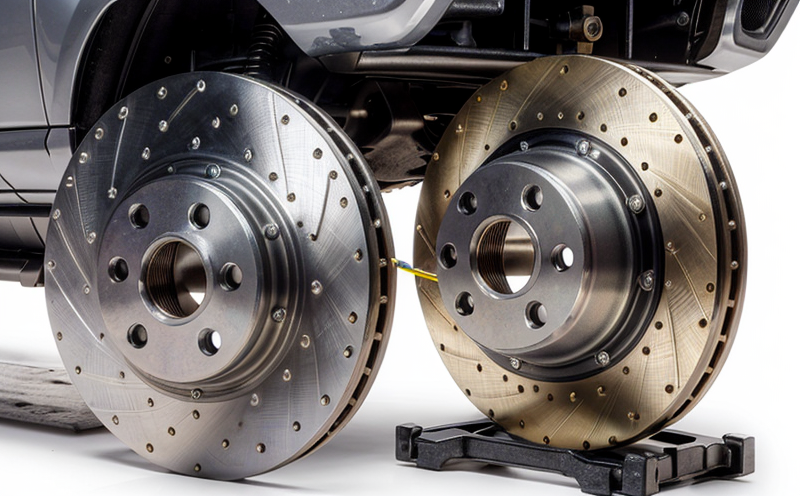

A Our laboratory service can accommodate various brake components, including pads, rotors, calipers, and drums.

Q How long does the testing process typically take?

A The duration of testing depends on the specific requirements of each client. We work closely with businesses to develop customized testing plans that meet their needs.

Q What kind of data can I expect from Eurolabs testing service?

A Our reports provide comprehensive data on brake component performance, including wear rates, thermal characteristics, and vibrational sensitivity.

Q Can you simulate specific driving conditions or environmental factors?

A Yes, our state-of-the-art equipment allows us to replicate a range of driving scenarios, including different road types, vehicle speeds, and weather conditions.

Q How can I ensure that my products meet industry standards for durability and performance?

A Eurolabs testing service provides businesses with the necessary data to inform design improvements or material selections. Our experts also offer recommendations on how to optimize product development to meet regulatory requirements.

Conclusion

In an industry where safety and reliability are paramount, Testing the Durability of Brake Components Under Vibrational Stress is a crucial step in ensuring road safety through product quality. By investing in Eurolabs laboratory service, businesses can

Enhance road safety

Reduce warranty claims

Meet regulatory requirements

Gain a competitive edge

Dont compromise on your products performance and durability. Trust Eurolab to provide you with the expertise and data-driven insights needed to create safer, more reliable brake components. Contact us today to learn more about our laboratory services and take the first step towards achieving excellence in product development.