Testing the durability of mechanical components

Unveiling the Strength of Your Mechanical Components Why Testing Durability Matters

In todays fast-paced industrial landscape, companies are constantly pushing the boundaries of innovation and efficiency. With the relentless pursuit of perfection comes the need for rigorous testing to ensure that mechanical components meet the demands of various environments and applications. This is where Testing the durability of mechanical components comes into play a laboratory service provided by Eurolab, designed to help businesses unlock the full potential of their products.

What is Testing the Durability of Mechanical Components?

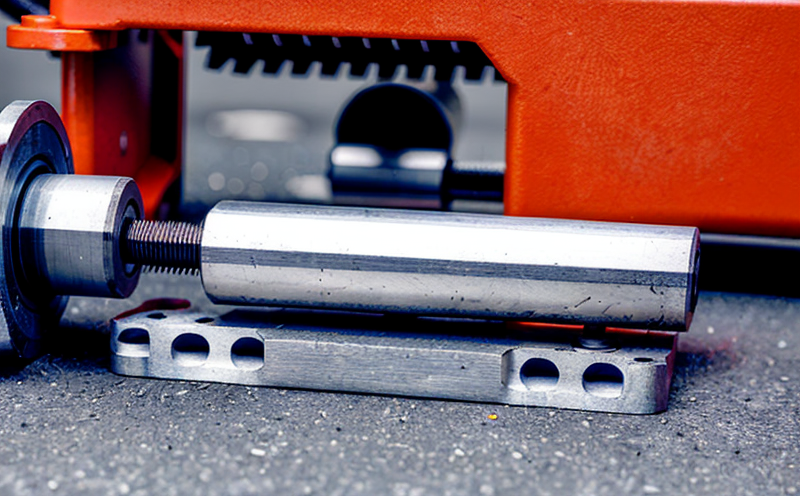

In simple terms, testing the durability of mechanical components involves subjecting them to various forms of stress and strain to assess their ability to withstand operational conditions. This process helps manufacturers identify weaknesses, optimize design, and improve overall product reliability. By simulating real-world scenarios in a controlled laboratory environment, Eurolabs expert technicians can determine whether your mechanical components meet the required standards for performance, safety, and longevity.

Why is Testing Durability Essential for Businesses?

The importance of testing durability cannot be overstated. Here are just a few reasons why

Improved Product Reliability By identifying potential weaknesses before they become major issues, businesses can reduce the likelihood of costly repairs, replacements, and recalls.

Enhanced Customer Satisfaction When mechanical components perform as expected, customers are more likely to be satisfied with their purchase, leading to increased loyalty and positive word-of-mouth marketing.

Reduced Warranty Claims By testing durability, companies can minimize warranty claims, which not only saves them money but also reduces administrative burdens.

Increased Product Lifespan By understanding the limitations of mechanical components, manufacturers can extend product lifespans, reducing waste and minimizing environmental impact.

Compliance with Industry Standards Testing durability helps businesses meet regulatory requirements and industry standards, ensuring that their products are safe for use in various applications.

Benefits of Using Eurolabs Testing Services

When it comes to testing the durability of mechanical components, Eurolab offers a comprehensive range of services designed to cater to your specific needs. Here are just some of the benefits you can expect

Customized Testing Programs Our team will work with you to develop tailored testing programs that meet your unique requirements and industry standards.

State-of-the-Art Equipment Eurolabs laboratory is equipped with cutting-edge equipment, ensuring accurate and reliable results.

Expert Analysis and Reporting Our technicians will provide detailed analysis and reporting on test results, helping you make informed decisions about product optimization and improvement.

Quick Turnaround Times We understand the importance of timely results. Our team works efficiently to ensure that testing is completed quickly without compromising accuracy.

What Types of Mechanical Components Can Be Tested?

Eurolabs testing services cover a wide range of mechanical components, including but not limited to

Engine and Transmission Components

Bearings and Gears

Pumps and Valves

Fasteners and Fittings

Motorized Systems and Robotics

Frequently Asked Questions (FAQs)

Q What types of testing can be performed on mechanical components?

A Our laboratory offers a comprehensive range of tests, including tensile strength testing, fatigue testing, impact testing, and more.

Q How do I know which testing program is right for my business?

A Our team will work with you to understand your specific needs and develop a customized testing program that meets your requirements.

Q Can Eurolab provide certification or compliance documentation after testing?

A Yes, our laboratory provides detailed reports and certifications to ensure that your products meet industry standards and regulatory requirements.

Q How long does the testing process typically take?

A The duration of testing varies depending on the type and complexity of the tests. Our team will work with you to establish a realistic timeline for completion.

Conclusion

In todays competitive industrial landscape, testing the durability of mechanical components is no longer an optional luxury its a necessity. By partnering with Eurolab, businesses can unlock the full potential of their products, reduce costs, and improve customer satisfaction. Whether youre looking to optimize design, improve product reliability, or meet industry standards, our comprehensive range of services has got you covered. Contact us today to discover how we can help take your business to the next level.

Additional Resources

For more information on testing the durability of mechanical components or to discuss your specific needs, please visit our website or contact us through our online form.