Testing the durability of small parts to prevent breakage during regular use

The Importance of Testing Durability Ensuring Small Parts withstanding Regular Use

In the fast-paced world of manufacturing and production, ensuring the reliability and durability of small parts is crucial to prevent breakage during regular use. A single defective product can lead to significant financial losses, damage to brand reputation, and even pose safety risks to consumers. This is where Eurolabs laboratory service, Testing Durability of Small Parts to Prevent Breakage During Regular Use, comes into play.

What is Testing Durability?

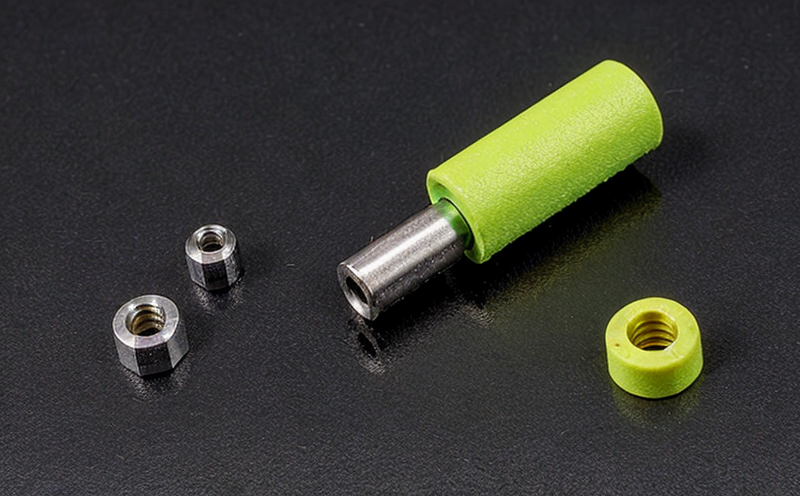

Testing the durability of small parts involves subjecting them to rigorous testing protocols to assess their ability to withstand the stresses and strains of regular use. This process simulates real-world conditions, allowing manufacturers to identify potential weaknesses in design or material selection. By doing so, businesses can make informed decisions about product development, reduce warranty claims, and enhance overall customer satisfaction.

Why is Testing Durability Essential for Businesses?

In todays competitive market, companies cannot afford to compromise on product quality. The consequences of defective products are far-reaching, affecting not only the bottom line but also brand reputation and consumer trust. Eurolabs testing services help businesses mitigate these risks by providing a comprehensive understanding of their products durability.

Advantages of Using Testing Durability Services

Eurolabs laboratory service offers numerous benefits to manufacturers, including

Reduced Warranty Claims By identifying potential weaknesses before product launch, companies can minimize warranty claims and associated costs.

Improved Product Reliability Rigorous testing ensures that small parts meet the required standards, reducing the likelihood of product failure during use.

Enhanced Customer Satisfaction Products that withstand regular use build trust with customers, leading to increased loyalty and repeat business.

Cost Savings Avoiding costly recalls, rework, and repair can significantly impact a companys bottom line.

Competitive Advantage Manufacturers that prioritize testing durability differentiate themselves from competitors, establishing a reputation for quality and reliability.

Key Benefits of Testing Durability Services

Accelerated Product Development Early detection of potential issues enables companies to make informed design changes, accelerating the product development process.

Improved Design Optimization Testing reveals areas for improvement, allowing designers to refine their creations and reduce material waste.

Reduced Material Waste By identifying optimal material selection and application, manufacturers can minimize waste and optimize resource usage.

QA Testing Durability of Small Parts

Q What types of small parts can be tested?

A Eurolabs laboratory service is versatile and accommodates a wide range of small parts, including plastics, metals, ceramics, and composites.

Q How does the testing process work?

A Our expert technicians employ various testing protocols, such as drop testing, vibration testing, and environmental chamber testing, to simulate real-world conditions.

Q What are the benefits of testing durability compared to traditional testing methods?

A Our comprehensive approach identifies potential weaknesses before product launch, allowing for informed design changes and cost savings.

Q How long does the testing process typically take?

A The duration of testing depends on the specific requirements of each project. Our experienced team will provide a customized timeline to ensure timely completion.

Q Can Eurolabs laboratory service accommodate large or complex projects?

A Yes, our state-of-the-art facilities and skilled technicians enable us to handle even the most intricate and demanding projects.

Conclusion

In conclusion, Testing Durability of Small Parts to Prevent Breakage During Regular Use is an indispensable service for manufacturers seeking to ensure product reliability and mitigate potential risks. By partnering with Eurolab, businesses can benefit from reduced warranty claims, improved customer satisfaction, and cost savings. Dont let defective products compromise your brands reputation choose Eurolabs laboratory services today and take the first step towards a more reliable future.

Eurolab Your Partner in Testing Durability

At Eurolab, our commitment to excellence is unwavering. Our experienced team of technicians and experts utilizes cutting-edge technology to provide comprehensive testing services tailored to your specific needs. Trust us to help you ensure the durability of small parts, guaranteeing that your products meet the highest standards of quality and reliability.

About Eurolab

Eurolab is a leading laboratory service provider dedicated to delivering high-quality testing solutions for manufacturers worldwide. Our mission is to empower businesses with the knowledge and expertise required to create reliable, efficient, and cost-effective products.

With our state-of-the-art facilities and expert technicians, we offer a wide range of services, including materials science testing, product validation, and quality control. Whether youre looking to optimize your design or ensure regulatory compliance, Eurolab is your trusted partner in the pursuit of excellence.

Join the Eurolab Community

Stay up-to-date with industry insights, best practices, and company news by joining our community today!