Testing the durability of toy joints to ensure they do not become loose or break during use

Testing the Durability of Toy Joints Ensuring Safety and Quality for Businesses

In todays competitive market, businesses in the toy industry must adhere to rigorous standards to ensure their products meet consumer expectations for safety and quality. One critical aspect of this is testing the durability of toy joints to prevent them from becoming loose or breaking during use. At Eurolab, our laboratory service specializes in conducting comprehensive tests on toy joints to guarantee that they can withstand the demands of playtime.

What is Testing the Durability of Toy Joints?

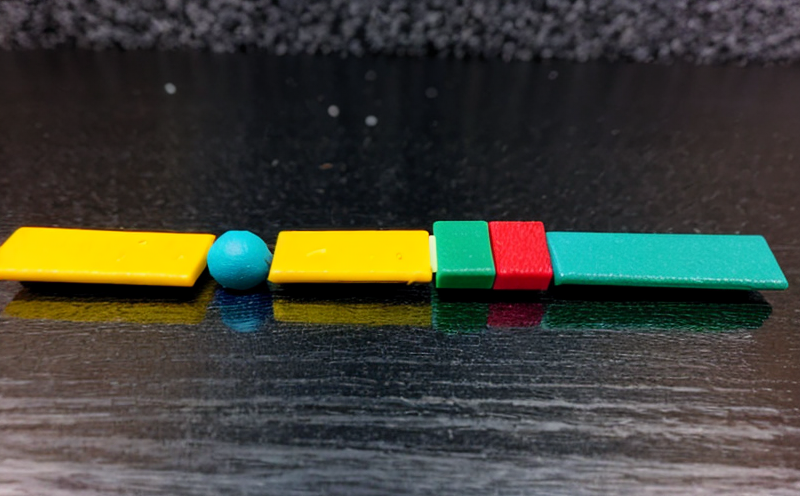

Testing the durability of toy joints involves subjecting the joint connections of a toy to various stresses and conditions to evaluate their ability to maintain structural integrity. This includes assessing the joints resistance to fatigue, impact, and wear, as well as its performance under different environmental conditions. The goal is to identify potential weaknesses or vulnerabilities that could compromise the toys overall safety.

Why is it Essential for Businesses?

The consequences of a poorly designed or manufactured toy can be severe. A loose or broken joint can not only render the toy unusable but also pose a significant risk to children, who may accidentally ingest small parts or suffer from injuries caused by sharp edges or points. Moreover, the reputation and brand image of a company can be severely damaged if their products are found to be defective.

According to the U.S. Consumer Product Safety Commission (CPSC), toys with loose or broken joints account for a significant number of reported incidents each year. In 2020 alone, there were over 100,000 reports of toy-related injuries in the United States, with many of these involving joint failures. By conducting rigorous testing on toy joints, businesses can minimize this risk and ensure that their products meet or exceed regulatory requirements.

Advantages of Testing the Durability of Toy Joints

Eurolabs laboratory service offers a range of benefits to businesses in the toy industry, including

Reduced Risk of Recalls By identifying potential issues with joint durability before products reach consumers, businesses can avoid costly recalls and minimize reputational damage.

Improved Safety Comprehensive testing ensures that toys meet or exceed safety standards, protecting children from harm and reducing the risk of liability for manufacturers.

Increased Confidence in Product Design Eurolabs expertise helps businesses optimize their product design, ensuring that joints are robust enough to withstand the demands of playtime without compromising safety.

Enhanced Quality Control Our testing services enable companies to refine their manufacturing processes, improving overall quality and reducing defects.

Compliance with Regulatory Requirements By working with Eurolab, businesses can ensure that their products meet or exceed regulatory requirements, including those set by the CPSC, EN 71, and other international standards.

Key Benefits for Businesses

Eurolabs testing services provide a range of key benefits to businesses in the toy industry, including

Enhanced Product Quality Our expert technicians use state-of-the-art equipment to conduct rigorous tests on toy joints, ensuring that products meet or exceed quality expectations.

Improved Manufacturing Processes By identifying areas for improvement through our testing services, businesses can refine their manufacturing processes and reduce defects.

Reduced Costs Companies that invest in comprehensive testing can avoid costly recalls, minimize product redesigns, and reduce the financial burden of liability claims.

Increased Customer Trust Eurolabs laboratory service helps businesses demonstrate their commitment to quality and safety, enhancing customer trust and loyalty.

Frequently Asked Questions

Q What types of tests do you conduct on toy joints?

A Our testing services include a range of methods, including impact testing, fatigue testing, wear testing, and environmental testing.

Q How long does the testing process take?

A The duration of our testing services varies depending on the specific requirements of each project. On average, our tests can be completed within 2-4 weeks.

Q What are the regulatory standards you follow for toy joint testing?

A Our laboratory adheres to a range of international standards, including CPSC, EN 71, and other relevant regulations.

Q Can I schedule testing at any time?

A Yes. We offer flexible scheduling options to accommodate your business needs.

Conclusion

Testing the durability of toy joints is an essential service for businesses in the toy industry, providing a critical safeguard against safety risks and regulatory non-compliance. By partnering with Eurolab, companies can ensure that their products meet or exceed quality expectations, reduce the risk of recalls, and maintain a strong reputation for safety and excellence.

At Eurolab, our expert technicians use state-of-the-art equipment to conduct comprehensive tests on toy joints, providing businesses with actionable insights to refine their product design and manufacturing processes. By investing in our testing services, companies can enhance customer trust, reduce costs, and optimize their competitive edge in the market.

Dont compromise on safety partner with Eurolab today to ensure that your toys meet or exceed regulatory requirements and provide consumers with a safe and enjoyable experience.