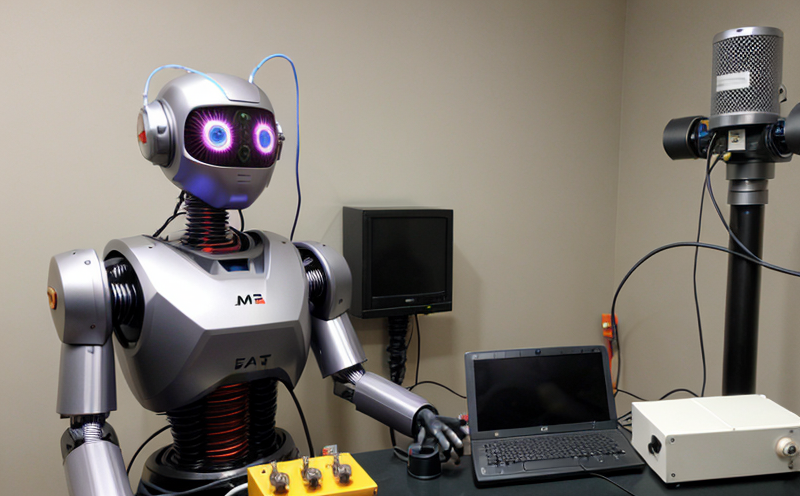

Testing the effect of electromagnetic interference (EMI) on robot sensors

Unlocking the Secrets of Electromagnetic Interference Why Testing EMI on Robot Sensors is Crucial for Businesses

In todays fast-paced world of robotics and automation, ensuring the reliability and accuracy of robotic systems is paramount. One often-overlooked but critical aspect of robot functionality is electromagnetic interference (EMI) testing. As robots increasingly find their way into various industries, including manufacturing, healthcare, and logistics, the need for EMI testing has never been more pressing. Eurolabs laboratory service, Testing the effect of electromagnetic interference on robot sensors, provides businesses with a critical tool to safeguard their investments and maintain compliance with industry standards.

What is Electromagnetic Interference (EMI) Testing?

Electromagnetic interference refers to the disturbance caused by an external energy source that affects the performance of electronic devices. In the context of robotics, EMI can manifest as signal degradation, malfunctioning, or even complete system failure. This can have far-reaching consequences, including equipment damage, data loss, and compromised operational safety.

Why is EMI Testing on Robot Sensors Essential?

As robots become more sophisticated, their reliance on advanced sensors increases. However, these sensors are vulnerable to electromagnetic interference, which can disrupt their functionality and lead to errors in navigation, perception, and control. The consequences of unchecked EMI exposure include

System downtime Malfunctioning or inaccurate sensor data can cause production delays, increased maintenance costs, and compromised productivity.

Data integrity Inaccurate or corrupted data can lead to incorrect decisions, impacting product quality, customer satisfaction, and ultimately, the bottom line.

Safety risks EMI exposure can compromise robotic systems ability to detect and respond to their environment, posing a risk to human life and property.

Benefits of Eurolabs Testing Service

Eurolabs laboratory service offers a comprehensive solution for testing the effect of electromagnetic interference on robot sensors. Our experts employ state-of-the-art equipment and techniques to simulate real-world EMI scenarios, providing actionable insights and recommendations for mitigating potential issues. Key benefits include

Improved system reliability Identify and address vulnerabilities before they lead to costly downtime or safety risks.

Enhanced data integrity Ensure that sensor data remains accurate and reliable, even in the presence of electromagnetic interference.

Compliance with industry standards Meet regulatory requirements for EMI testing and reduce the risk of non-compliance penalties.

Increased efficiency Minimize maintenance costs and optimize production workflows by identifying potential issues early on.

Reduced liability Demonstrate a commitment to safety and product quality, reducing the risk of litigation or reputational damage.

Key Benefits

EMI testing for various industries Eurolabs service caters to diverse sectors, including automotive, aerospace, healthcare, and more.

Customized test plans Our experts work with clients to develop tailored test protocols that address specific EMI concerns.

State-of-the-art equipment Stay up-to-date with the latest technology and methodologies in EMI testing and analysis.

Comprehensive reporting Receive detailed reports outlining test results, recommendations, and corrective actions.

QA Common Questions About EMI Testing on Robot Sensors

What types of sensors are most susceptible to EMI?

Most robotic systems rely on a combination of sensors, including accelerometers, gyroscopes, magnetometers, and pressure sensors.

How do I determine the level of EMI testing required for my robot system?

Consult with Eurolabs experts to develop a customized test plan based on your specific requirements and industry standards.

What is the typical duration of an EMI testing project?

Project timelines vary depending on the scope, complexity, and industry-specific regulations.

Can I integrate EMI testing into my existing quality control procedures?

Absolutely Eurolabs service is designed to complement your existing processes, ensuring seamless integration.

Conclusion

In todays increasingly complex world of robotics and automation, electromagnetic interference poses a significant threat to system reliability, data integrity, and operational safety. By investing in EMI testing on robot sensors through Eurolab, businesses can safeguard their investments, maintain compliance with industry standards, and stay ahead of the competition. Dont risk your reputation or regulatory standing trust Eurolabs laboratory service to ensure your robotic systems operate at peak performance and efficiency.