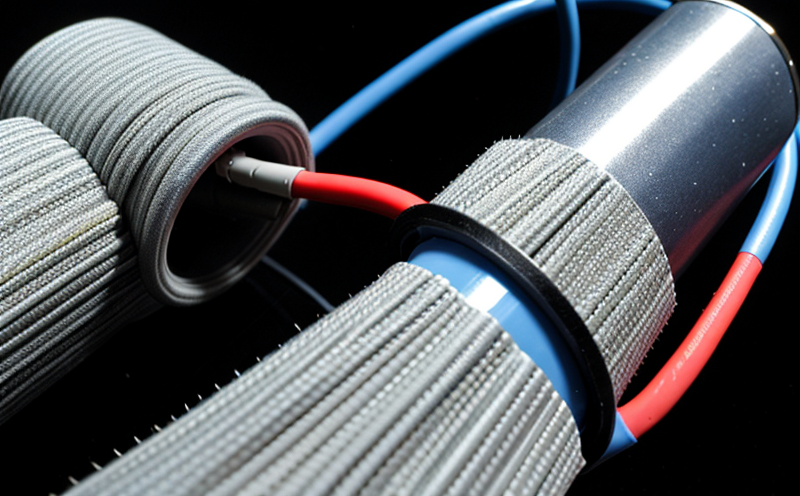

Testing the Performance of Cables with Reinforced Sleeves

The Importance of Testing the Performance of Cables with Reinforced Sleeves Why Your Business Needs It

In todays fast-paced and highly interconnected world, cables are an essential component of countless industries, including electronics, automotive, aerospace, and more. With the constant demand for faster, more reliable, and efficient data transmission, the quality and performance of these cables have never been under greater scrutiny. Thats where Testing the Performance of Cables with Reinforced Sleeves, a cutting-edge laboratory service provided by Eurolab, comes in.

At Eurolab, we understand that your business relies on the accuracy and consistency of its cable products. A single faulty or subpar cable can lead to costly downtime, damaged equipment, and compromised product quality. Thats why our comprehensive testing services are designed to ensure that your cables meet the highest standards of performance and reliability.

The Benefits of Testing the Performance of Cables with Reinforced Sleeves

Our Testing the Performance of Cables with Reinforced Sleeves service is a critical step in ensuring the integrity and quality of your cable products. By investing in our laboratory testing, you can reap numerous benefits that will ultimately drive business growth and success.

Here are just some of the key advantages of using Eurolabs Testing the Performance of Cables with Reinforced Sleeves

Improved Product Reliability Our rigorous testing procedures help identify potential weaknesses or defects in your cable products. By addressing these issues early on, you can prevent costly product recalls and minimize downtime.

Enhanced Customer Satisfaction When you partner with Eurolab for Testing the Performance of Cables with Reinforced Sleeves, youre demonstrating a commitment to delivering high-quality products that meet customer expectations.

Increased Efficiency and Productivity By streamlining your production processes through informed design and manufacturing decisions, you can optimize product development timelines and reduce overall costs.

Reduced Risk and Liability Our testing services help mitigate the risk of product failure or liability claims. With a comprehensive understanding of your cable products performance characteristics, you can make informed decisions about usage, maintenance, and replacement.

Compliance with Industry Standards We ensure that our testing procedures align with international industry standards, including IEC, IEEE, and ISO. This guarantee helps ensure seamless integration with existing quality control systems and regulatory frameworks.

How Eurolabs Testing the Performance of Cables with Reinforced Sleeves Works

Our team of experienced engineers and technicians employ advanced equipment and methodologies to comprehensively evaluate the performance of cables with reinforced sleeves. Our testing protocols cover a range of critical parameters, including

Mechanical Properties We assess cable flexibility, tensile strength, and resistance to abrasion and flexural stress.

Electrical Performance Our tests examine voltage drop, current-carrying capacity, and insulation breakdown voltage.

Chemical Resistance We evaluate the cables performance under exposure to various environmental factors, such as temperature, humidity, and chemicals.

Thermal Properties Our testing procedures assess thermal stability, heat dissipation, and resistance to thermal shock.

By examining these critical aspects of cable performance, we provide you with actionable insights that inform design improvements, material selection, and manufacturing process optimization.

Frequently Asked Questions

Weve compiled a list of commonly asked questions about our Testing the Performance of Cables with Reinforced Sleeves service

Q What types of cables can be tested using this service?

A Our testing services are available for all types of cables with reinforced sleeves, including coaxial, twisted pair, and fiber optic cables.

Q How long does a typical testing cycle take?

A The duration of our testing procedures varies depending on the type of cable and the scope of testing required. Typically, a comprehensive test cycle takes anywhere from several hours to several days.

Q Can I customize my testing protocol or requirements?

A Yes! We understand that every business has unique needs and priorities. Our experienced team will work closely with you to develop a tailored testing plan that meets your specific requirements.

Q What is the cost of this service, and how do you bill for it?

A Our pricing structure varies depending on the scope and complexity of the testing required. Well provide you with a detailed quote based on your specific needs and expectations.

Conclusion

In an increasingly competitive market where reliability, efficiency, and innovation are paramount, Eurolabs Testing the Performance of Cables with Reinforced Sleeves is an indispensable resource for businesses committed to delivering top-quality cable products. By partnering with us, youll not only meet industry standards but also future-proof your operations through informed design decisions.

At Eurolab, were dedicated to providing unparalleled laboratory services that help businesses like yours thrive in the ever-evolving landscape of cable technology. Contact us today to learn more about our comprehensive testing solutions and discover how our expertise can elevate your products performance and drive business success!