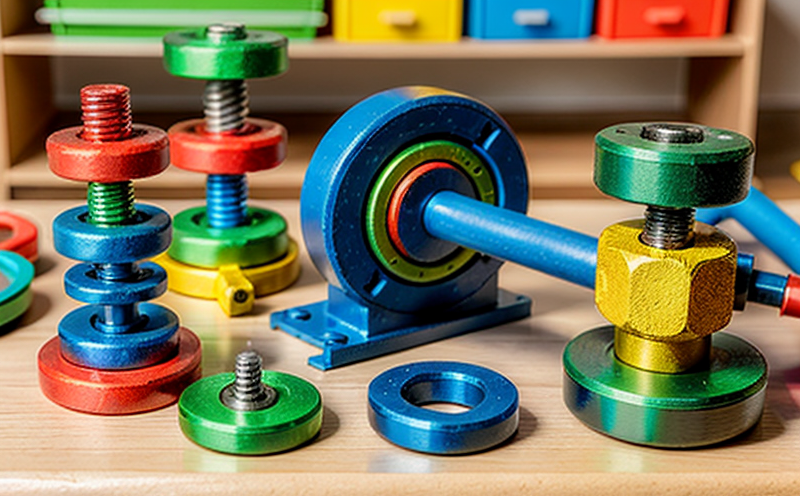

Testing the rotational strength of components in toys and juvenile products

The Importance of Rotational Strength Testing in Toys and Juvenile Products Ensuring Safety for Your Customers

As a manufacturer of toys and juvenile products, ensuring the safety and quality of your goods is paramount to protecting your customers and maintaining a strong reputation. One critical aspect of product testing that often gets overlooked is rotational strength testing the examination of how well components within a toy or juvenile product can withstand rotation forces without breaking or causing injury.

At Eurolab, we offer a comprehensive laboratory service designed specifically for companies like yours Testing the rotational strength of components in toys and juvenile products. Our expert technicians utilize state-of-the-art equipment to assess the performance of your products under various rotational conditions, providing you with actionable data to optimize design and manufacturing processes. In this article, well delve into the benefits of rotational strength testing, its importance for businesses, and answer frequently asked questions about our service.

Why Rotational Strength Testing Matters

Rotational forces can be particularly hazardous in toys and juvenile products, as they may cause components to detach or shatter, leading to accidents and injuries. The consequences can be severe not only do these incidents damage your brands reputation, but you also face significant financial penalties for non-compliance with regulatory standards.

To mitigate these risks, rotational strength testing is essential for ensuring the safety and reliability of your products. By conducting rigorous testing, you can identify areas for improvement in design and manufacturing, preventing potential hazards before they reach the market.

Advantages of Rotational Strength Testing

So, what are the key benefits of using our laboratory service? Lets take a closer look

Improved Product Safety Our testing helps you identify potential safety issues, allowing you to make informed design decisions that minimize risks and protect consumers.

Compliance with Regulatory Standards By adhering to rigorous testing protocols, you can ensure your products meet or exceed industry standards for rotational strength, reducing the likelihood of regulatory non-compliance.

Increased Customer Trust When customers know that a product has undergone thorough rotational strength testing, they feel more confident in its safety and quality, fostering long-term loyalty and advocacy.

Enhanced Brand Reputation Demonstrating a commitment to product safety through rotational strength testing reinforces your brands values and reputation for excellence, setting you apart from competitors.

Reduced Liability By identifying potential hazards early on, you can take corrective action before products reach the market, minimizing the risk of costly lawsuits and associated damages.

Benefits for Businesses

Rotational strength testing offers numerous benefits for businesses in the toy and juvenile product industry

Cost Savings By optimizing design and manufacturing processes through rotational strength testing, you can reduce production costs and minimize waste.

Time Efficiency Our expert technicians work quickly to deliver test results, allowing you to make informed decisions without unnecessary delays.

Competitive Advantage Demonstrating a commitment to safety and quality through rotational strength testing sets your company apart from competitors and enhances its market position.

Frequently Asked Questions

Weve received many questions about our laboratory service. Here are some of the most common

Q What types of toys and juvenile products do you test for rotational strength?

A Our expert technicians can assess a wide range of products, including but not limited to, bicycles, scooters, tricycles, strollers, car seats, and high chairs.

Q How is rotational strength testing conducted at Eurolab?

A We utilize state-of-the-art equipment and follow established industry standards for rotational strength testing. Our expert technicians carefully prepare samples for analysis, applying various rotation forces to simulate real-world conditions.

Q What kind of data can I expect from the test results?

A We provide detailed reports that outline the rotational strength of your products under different conditions, including maximum tolerable rotation forces and any potential hazards or weaknesses.

Q How long does the testing process typically take?

A Our expert technicians work efficiently to deliver test results within a short timeframe. The duration of testing depends on factors such as product complexity and number of samples tested.

Q What kind of follow-up support can I expect from Eurolab after receiving my test results?

A Were committed to ensuring you have everything you need to improve your products safety and performance. Our expert technicians are available for consultation, answering questions and providing guidance on implementing design changes or addressing any issues that arose during testing.

Conclusion

In conclusion, rotational strength testing is a critical aspect of product development in the toy and juvenile product industry. By partnering with Eurolab, you can ensure your products meet or exceed regulatory standards for safety and performance. Our expert technicians offer comprehensive laboratory services designed to optimize design and manufacturing processes, reducing risks, costs, and liabilities associated with non-compliance.

Dont compromise on product safety choose the best. Contact us today to schedule your rotational strength testing and take the first step towards safeguarding your customers trust and enhancing your brands reputation for excellence.

-

Verifying that toy parts, such as screws and fasteners, remain secure under twisting forces

-

Assessing the durability of rotating parts, such as wheels or gears, under torque stress

-

Ensuring that toys with moving parts are safe and durable under twisting motions

-

Testing toys to ensure that fasteners and joints are not prone to loosening or detaching

-

Simulating real-life twisting actions that children might perform on toys

-

Verifying that products with rotating components can handle the torque generated during use

-

Testing toys and products for compliance with torque-related safety standards

-

Evaluating the resilience of toys with handles, knobs, or turning mechanisms under torque

-

Ensuring that toys do not break or malfunction when subjected to rotational stress

-

Testing the ability of toys with screw-in parts to withstand twisting forces without damage

-

Simulating continuous twisting and turning motions to evaluate product durability

-

Ensuring that toy components designed for rotation remain intact under twisting or turning

-

Testing the ability of toy joints and connections to withstand torque without loosening

-

Verifying that products with rotating parts do not present safety hazards when under stress

-

Ensuring that materials used in toys retain their strength under torque-related stress

-

Simulating various torque forces to ensure toy durability in different play scenarios

-

Verifying that battery compartments and other parts remain secure under twisting or torquing

-

Testing how toys with multiple components, like puzzles or constructions, hold up under torque

-

Assessing the effect of torque on the longevity and safety of juvenile products

-

Evaluating the force at which toy parts break, detach, or malfunction under twisting actions

-

Ensuring compliance with international torque testing standards for toys and juvenile products