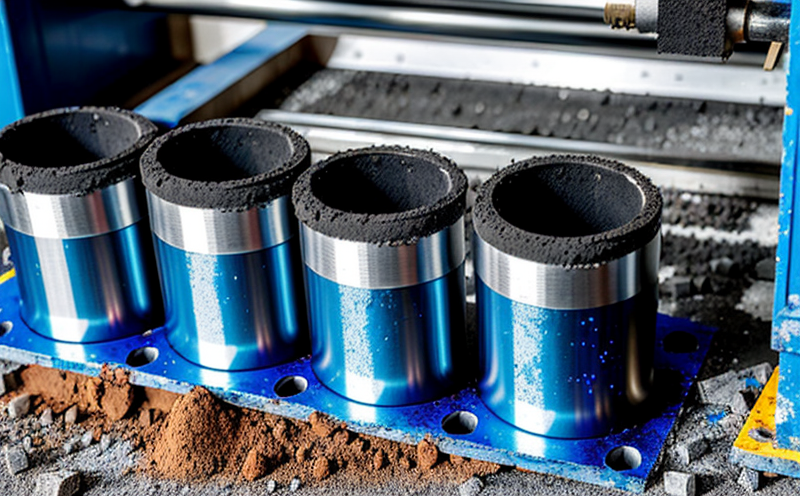

Thermal expansion properties tested in thermal shock testing

Understanding Thermal Expansion Properties Why Thermal Shock Testing Matters

In todays fast-paced world of manufacturing and innovation, products are constantly being pushed to their limits. Whether its a cutting-edge electronic device, a high-performance sports car, or a revolutionary medical equipment, companies need to ensure that their products can withstand the harsh conditions of real-world use. One critical aspect of product testing is thermal expansion properties, which play a vital role in determining a materials behavior under varying temperatures.

What are Thermal Expansion Properties?

Thermal expansion refers to the tendency of materials to change size or shape when exposed to temperature fluctuations. This phenomenon occurs due to the vibration and movement of atoms within the materials crystal lattice structure, causing it to expand or contract in response to heat or cold. Understanding a materials thermal expansion properties is essential for predicting how it will behave under different environmental conditions.

Why Thermal Shock Testing Matters

Thermal shock testing, a laboratory service provided by Eurolab, involves subjecting materials to rapid and extreme temperature changes to evaluate their thermal expansion properties. This rigorous testing protocol simulates real-world scenarios where products may be exposed to sudden temperature fluctuations, such as

Rapid changes in ambient temperature

Exposure to extreme temperatures during transportation or storage

Thermal cycling between high and low temperatures

By conducting thermal shock testing on materials, companies can identify potential issues before they become costly problems. This proactive approach helps prevent product failures, reduces warranty claims, and ensures customer satisfaction.

Advantages of Using Thermal Expansion Properties Tested in Thermal Shock Testing

Eurolabs thermal expansion properties tested in thermal shock testing offers numerous benefits for businesses

Improved Product Reliability By identifying potential issues before mass production, companies can ensure their products meet the required standards and perform as expected.

Enhanced Customer Satisfaction Thermal shock testing helps prevent product failures, reducing warranty claims and ensuring customer satisfaction.

Cost Savings Identifying and addressing thermal expansion issues early on saves companies from costly rework or replacement processes.

Competitive Advantage Companies that prioritize thermal expansion properties testing demonstrate their commitment to quality and reliability, setting them apart in the market.

Key Benefits of Thermal Expansion Properties Tested in Thermal Shock Testing

Here are some key benefits of using Eurolabs thermal expansion properties tested in thermal shock testing

Precise Temperature Control Our state-of-the-art equipment allows for precise control over temperature fluctuations, ensuring accurate and reliable results.

Comprehensive Analysis We provide detailed reports on material performance under various thermal conditions, helping companies identify potential issues.

Scalable Testing Capabilities Whether you need to test a small sample or a large batch of materials, Eurolabs thermal shock testing equipment can accommodate your needs.

Rapid Turnaround Times Our experienced team ensures timely completion of tests, allowing companies to quickly integrate the results into their product development cycle.

QA Thermal Expansion Properties Tested in Thermal Shock Testing

Q What is thermal expansion?

A Thermal expansion refers to the tendency of materials to change size or shape when exposed to temperature fluctuations.

Q Why is thermal shock testing necessary?

A Thermal shock testing helps companies identify potential issues related to material behavior under varying temperatures, ensuring product reliability and performance.

Q What are the benefits of using Eurolabs thermal expansion properties tested in thermal shock testing?

A Our service offers improved product reliability, enhanced customer satisfaction, cost savings, and a competitive advantage due to prioritized quality and reliability.

Q How does Eurolabs equipment ensure precise temperature control?

A Our state-of-the-art equipment allows for precise control over temperature fluctuations, ensuring accurate and reliable results.

Conclusion

In todays fast-paced world of product development, companies need to prioritize testing and validation to ensure their products meet the required standards. Thermal expansion properties tested in thermal shock testing is a critical aspect of material evaluation that helps predict behavior under varying temperatures. By partnering with Eurolab for this laboratory service, businesses can reap numerous benefits, including improved product reliability, enhanced customer satisfaction, cost savings, and a competitive advantage.

Dont risk your products reputation or performance due to inadequate thermal expansion testing. Trust Eurolabs expertise in thermal shock testing to help you develop high-quality materials that meet the demands of real-world use. Contact us today to learn more about our comprehensive laboratory services and how we can support your product development needs.