The Power of Predictive Modeling Unlocking Efficiency with Thermal Load Simulation

In todays fast-paced business landscape, companies are constantly seeking innovative ways to optimize their operations, reduce costs, and stay ahead of the competition. One critical aspect that often goes overlooked is the management of thermal loads a crucial factor in maintaining equipment efficiency, ensuring product quality, and preventing downtime. Thats where Thermal Load Simulation comes into play, a cutting-edge laboratory service offered by Eurolab. By leveraging this powerful tool, businesses can make informed decisions, mitigate risks, and reap significant benefits.

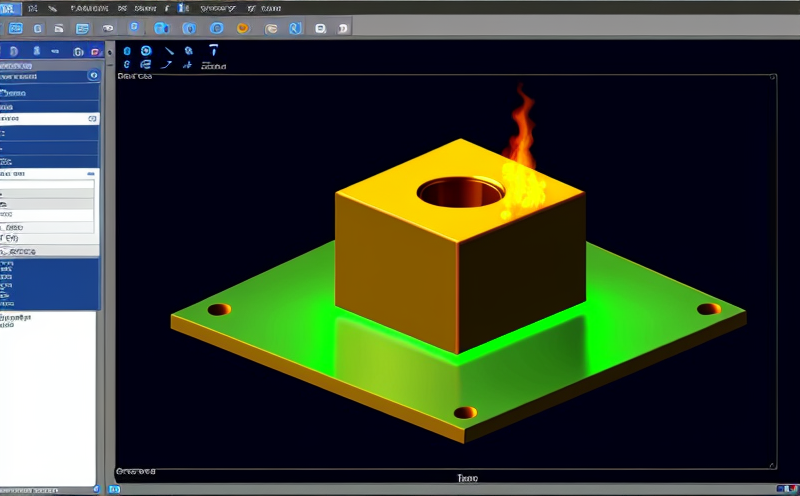

What is Thermal Load Simulation?

Thermal Load Simulation is an advanced analytical technique used to predict the thermal performance of electrical equipment under various operating conditions. This sophisticated service involves modeling complex heat transfer phenomena within devices, such as transformers, motors, and generators, allowing for a deeper understanding of their thermal behavior. By simulating real-world scenarios, Thermal Load Simulation enables engineers and decision-makers to anticipate potential issues, optimize design parameters, and minimize the risk of equipment failure.

Why is Thermal Load Simulation Essential for Businesses?

In an era where efficiency and reliability are paramount, Thermal Load Simulation offers numerous advantages that can transform your organizations operations. Some of the key benefits include

Reduced Energy Consumption By optimizing thermal performance, companies can decrease energy expenditure, lower greenhouse gas emissions, and contribute to a more sustainable future.

Increased Equipment Lifespan Predictive modeling helps identify potential hotspots and areas prone to overheating, allowing for timely interventions that extend the life of critical equipment.

Enhanced Product Quality Thermal Load Simulation ensures that products meet stringent quality standards by simulating operating conditions and identifying potential defects or weaknesses.

Improved Maintenance Scheduling By anticipating maintenance needs, companies can schedule downtime during off-peak hours, minimizing disruptions to production schedules.

Cost Savings Reduced energy consumption, extended equipment lifespan, and optimized maintenance scheduling all contribute to significant cost savings for businesses.

Competitive Advantage Companies that adopt Thermal Load Simulation demonstrate a commitment to innovation, efficiency, and customer satisfaction differentiators that can set them apart from competitors.

Unlocking Efficiency with Eurolabs Thermal Load Simulation

Eurolabs expert team of scientists and engineers is dedicated to providing top-notch laboratory services, including Thermal Load Simulation. Our state-of-the-art facilities and cutting-edge technology enable us to deliver precise, data-driven insights that empower businesses to make informed decisions.

Some key benefits of working with Eurolab include

Rapid Results Our team ensures prompt delivery of results, allowing companies to quickly incorporate simulation findings into their decision-making processes.

Customized Solutions We tailor our services to meet the unique needs of each client, providing tailored solutions that address specific business challenges.

Expert Guidance Eurolabs experienced engineers and scientists offer expert guidance and support throughout the project lifecycle, ensuring seamless collaboration and optimized outcomes.

Frequently Asked Questions

Q What types of equipment can be simulated using Thermal Load Simulation?

A Our laboratory services cover a wide range of electrical equipment, including transformers, motors, generators, and more.

Q How long does the simulation process typically take?

A The duration of the simulation process depends on various factors, such as project complexity and data availability. Our team will provide a customized timeline for each project.

Q Can Thermal Load Simulation be used to optimize existing equipment or is it primarily suited for new designs?

A Both! Eurolabs expertise spans both new design optimization and retrofits of existing equipment, ensuring that our clients can reap the benefits of simulation regardless of their current setup.

Q What kind of data do I need to provide for Thermal Load Simulation?

A We require detailed specifications, performance characteristics, and operating conditions for the equipment in question. Our team will work closely with you to ensure that all necessary information is gathered and analyzed.

Conclusion

In an increasingly competitive business landscape, companies must continually seek ways to innovate, optimize, and reduce costs. Thermal Load Simulation offers a powerful solution for achieving these goals by predicting thermal performance, optimizing design parameters, and ensuring equipment reliability. By partnering with Eurolab, businesses can unlock the full potential of this cutting-edge technology, driving efficiency, productivity, and customer satisfaction. Dont miss out on the opportunity to transform your operations contact us today to learn more about our Thermal Load Simulation services!