Thermal Management Testing

Unlocking Efficiency The Power of Thermal Management Testing

In todays fast-paced business landscape, staying ahead of the curve is crucial for success. One often-overlooked yet vital aspect of product development and manufacturing is thermal management testing. As companies push the boundaries of innovation, they must also ensure their products can withstand extreme temperatures and environmental conditions without compromising performance or safety.

This is where Eurolabs Thermal Management Testing laboratory service comes in a comprehensive solution designed to help businesses optimize their products for optimal performance under various temperature conditions.

What is Thermal Management Testing?

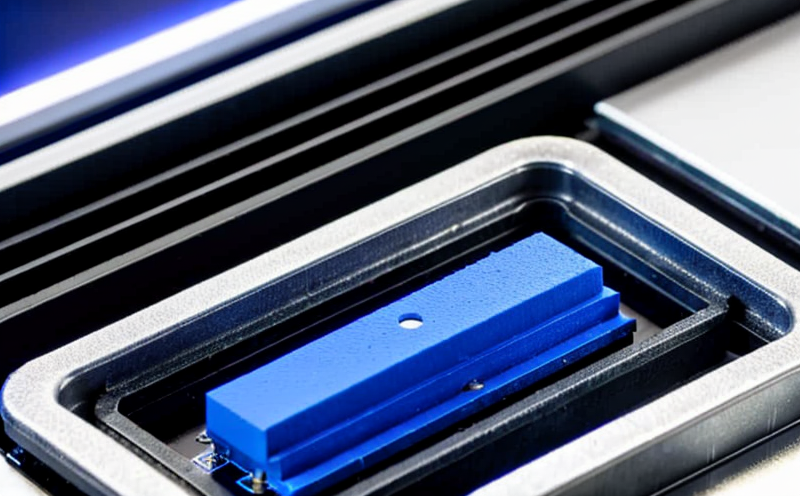

Thermal management testing involves subjecting electronic components, materials, and finished products to controlled thermal environments to assess their behavior under extreme temperatures. This includes evaluating their

Operating temperature ranges

Temperature cycling (rapid heating and cooling)

Humidity exposure

Corrosion resistance

By conducting thorough thermal management testing, businesses can identify potential issues before they become major problems. Our expert technicians at Eurolab utilize state-of-the-art equipment to simulate real-world scenarios, providing actionable insights that enable companies to refine their products and optimize their manufacturing processes.

The Advantages of Thermal Management Testing

The benefits of incorporating thermal management testing into your product development cycle are numerous

Improved Product Reliability By identifying temperature-related weaknesses early on, you can address issues before they affect performance or compromise safety.

Enhanced Performance Optimizing products for specific temperature ranges ensures they operate within their designed capabilities, reducing the risk of failure and increasing overall efficiency.

Reduced Production Costs Identifying potential issues during testing saves resources by avoiding costly redesigns, rework, or even product recalls.

Compliance with Industry Standards Thermal management testing helps ensure products meet regulatory requirements for temperature-related performance, safeguarding your business from costly non-compliance penalties.

Key Benefits of Eurolabs Thermal Management Testing

Our comprehensive service offers the following key benefits

Cost Savings Our experienced team and advanced equipment minimize testing time and costs.

Accurate Results State-of-the-art instrumentation provides precise data for informed decision-making.

Customized Solutions We tailor our services to meet your specific needs, ensuring you receive actionable insights tailored to your products.

Expert Support Our technicians are trained to handle complex testing requirements, providing expert guidance throughout the process.

Thermal Management Testing Applications

Our service is suitable for a wide range of industries and applications, including

Aerospace and Defense Ensure electronic components withstand extreme temperatures and environmental conditions in aerospace and defense applications.

Automotive Test automotive components for temperature-related performance, ensuring optimal operation under various driving conditions.

Electronics Evaluate the thermal performance of consumer electronics, industrial equipment, or other electronic devices.

Medical Devices Subject medical devices to simulated operating environments to guarantee reliability and safety.

Frequently Asked Questions (FAQs)

Weve compiled a list of common questions about our Thermal Management Testing service

Q What types of testing can you perform?

A Our laboratory offers a range of thermal management tests, including temperature cycling, humidity exposure, and corrosion resistance evaluations.

Q How do I prepare my product for testing?

A Well provide detailed instructions on preparing your product for testing, ensuring that its properly packaged and configured for optimal results.

Q What kind of data can I expect from the testing process?

A Our expert technicians will provide a comprehensive report detailing temperature-related performance, including any issues or areas for improvement.

Q How long does the testing process typically take?

A The length of time required for thermal management testing varies depending on the specific test requirements. Well work with you to develop a customized timeline that meets your needs.

Conclusion

In todays competitive business landscape, its essential to prioritize product performance and safety through thorough thermal management testing. Eurolabs expert technicians and state-of-the-art equipment ensure accurate results and actionable insights tailored to your specific needs.

By partnering with us for Thermal Management Testing, youll unlock efficiency gains, reduce production costs, and enhance the overall quality of your products. Dont let temperature-related issues compromise your business trust Eurolab to provide the expertise and testing capabilities you need to succeed.