UV Degradation Testing for Marine Materials

The Unyielding Power of Sunlight Understanding UV Degradation Testing for Marine Materials

As the worlds oceans continue to play a vital role in shaping our planets climate and ecosystems, the need for durable and long-lasting marine materials has never been more pressing. From sailboat masts to underwater equipment, marine materials are exposed to some of the harshest environmental conditions on Earth extreme temperatures, corrosive sea salt, and the relentless barrage of ultraviolet (UV) radiation.

Among these conditions, UV degradation testing for marine materials is an essential laboratory service that helps businesses ensure their products can withstand the unforgiving marine environment. At Eurolab, our team of expert scientists specializes in providing comprehensive UV degradation testing services to help manufacturers, engineers, and researchers create materials that meet the rigorous demands of the marine industry.

What is UV Degradation Testing for Marine Materials?

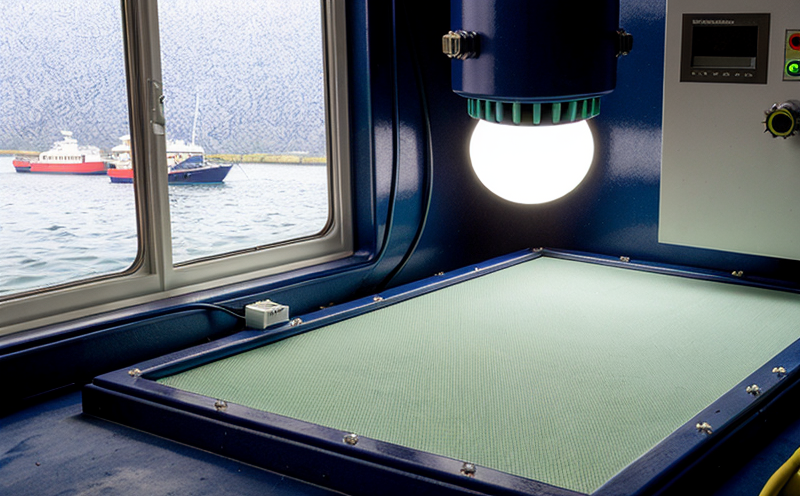

UV degradation testing measures the impact of UV radiation on the physical properties and chemical composition of marine materials. This type of testing simulates real-world exposure conditions to determine how materials perform over extended periods, taking into account factors such as wavelength, intensity, and duration.

By using advanced laboratory equipment and protocols, our team at Eurolab conducts rigorous testing to assess a range of material characteristics, including

Color stability

Strength retention

Chemical composition changes

Surface roughening or cracking

This essential information enables manufacturers to identify areas for improvement, optimize their products performance, and ensure compliance with industry standards.

Advantages of UV Degradation Testing for Marine Materials

The advantages of using Eurolabs UV degradation testing services are numerous

Increased Product Durability By simulating real-world exposure conditions, our team helps you create materials that can withstand the marine environments extreme stresses.

Improved Performance Reliability Our comprehensive testing ensures your products meet the exacting requirements of the marine industry, reducing the risk of premature failure and costly repairs.

Enhanced Safety Features Understanding how materials degrade under UV exposure enables designers to incorporate safety features that prevent accidents and injuries.

Compliance with Industry Standards Eurolabs expert services ensure your products comply with relevant standards and regulations, such as those outlined by international organizations like ISO and ASTM.

Cost Savings By identifying areas for improvement early on, our testing helps you avoid costly re-designs and revisions later in the development process.

Key Benefits of UV Degradation Testing

Here are some of the key benefits of using Eurolabs UV degradation testing services

Early Identification of Material Weaknesses

Optimized Material Formulations

Improved Manufacturing Efficiency

Enhanced Product Lifespan

Reduced Maintenance and Repair Costs

Compliance with Regulatory Requirements

Frequently Asked Questions (FAQs)

Q What types of marine materials can be tested using UV degradation testing?

A Our team at Eurolab specializes in testing a wide range of marine materials, including polymers, composites, metals, and coatings.

Q How long does the testing process typically take?

A The duration of our testing services varies depending on the specific requirements of your project. We work closely with clients to determine the most efficient testing schedule possible.

Q What are the benefits of using UV degradation testing over traditional methods?

A Our advanced laboratory equipment and protocols provide a more accurate representation of real-world exposure conditions, giving you a clearer understanding of material performance under UV stress.

Q Can I conduct my own UV degradation testing in-house?

A While some basic testing can be done in-house, our team at Eurolab possesses extensive expertise and specialized equipment to deliver comprehensive results. In-house testing may not capture the full scope of material behavior under UV exposure.

Conclusion

In an industry where even the smallest compromise can have far-reaching consequences, understanding the impact of UV degradation on marine materials is essential for businesses seeking to establish themselves as leaders in their field. At Eurolab, our dedicated team offers a range of services that cater to your unique needs and help you create products that meet the demands of the marine environment.

Dont let the unrelenting power of sunlight compromise your products performance. Contact us today to learn more about our UV degradation testing for marine materials and discover how Eurolab can support your business in creating durable, long-lasting solutions for the oceans harshest conditions.