UV resistance testing for coatings on metals

Unlock the Secrets of UV Resistance Testing for Coatings on Metals A Game-Changer for Businesses

In todays fast-paced world, businesses are constantly seeking innovative solutions to enhance their products and stay ahead of the competition. One crucial aspect that often gets overlooked is the durability and longevity of coatings on metals. Exposure to ultraviolet (UV) radiation can cause these coatings to degrade, leading to a range of problems, including discoloration, cracking, and even complete failure.

This is where UV resistance testing for coatings on metals comes into play a laboratory service provided by Eurolab that empowers businesses to predict the performance of their coatings under real-world conditions. By understanding the effects of UV radiation on your coatings, you can make informed decisions about product design, material selection, and manufacturing processes.

The Importance of UV Resistance Testing for Coatings on Metals

Coatings on metals are a ubiquitous feature in various industries, including automotive, aerospace, construction, and electronics. These coatings serve multiple purposes, such as corrosion protection, aesthetic enhancement, and functional performance. However, their exposure to UV radiation can lead to a range of issues

Loss of adhesion Coatings may delaminate or separate from the metal substrate, compromising its protective properties.

Color change Coatings can undergo color shifts or become discolored, affecting the overall appearance and aesthetic value of the product.

Material degradation Coatings may break down over time, leading to a loss of functional properties, such as scratch resistance or chemical resistance.

Conducting UV resistance testing for coatings on metals is essential for businesses looking to

Improve product performance By understanding how your coatings respond to UV radiation, you can design and develop products that meet the demands of various environments.

Enhance durability Testing your coatings resistance to UV radiation helps ensure they remain effective over time, reducing maintenance costs and extending product lifespan.

Reduce failures Early detection of potential issues enables proactive measures to be taken, minimizing the risk of costly repairs or replacements.

The Advantages of Using UV Resistance Testing for Coatings on Metals

Eurolabs comprehensive UV resistance testing services offer a range of benefits that can transform your business

Key Benefits

Predictive insights Gain valuable information about how your coatings will perform in real-world conditions, allowing you to make informed decisions about product development and manufacturing processes.

Cost savings Early detection of potential issues enables proactive measures to be taken, reducing the risk of costly repairs or replacements.

Increased efficiency With a thorough understanding of your coatings performance, you can streamline production, reduce waste, and optimize resource allocation.

Improved product quality By testing and optimizing your coatings for UV resistance, you can create products that meet the demands of various environments, enhancing customer satisfaction and loyalty.

Compliance with regulations Many industries have strict guidelines for coating performance under different environmental conditions. Conducting UV resistance testing ensures compliance with these standards.

Additional Advantages

Innovative solutions Eurolabs expert team will work closely with you to develop tailored testing protocols that cater to your specific needs, pushing the boundaries of what is possible.

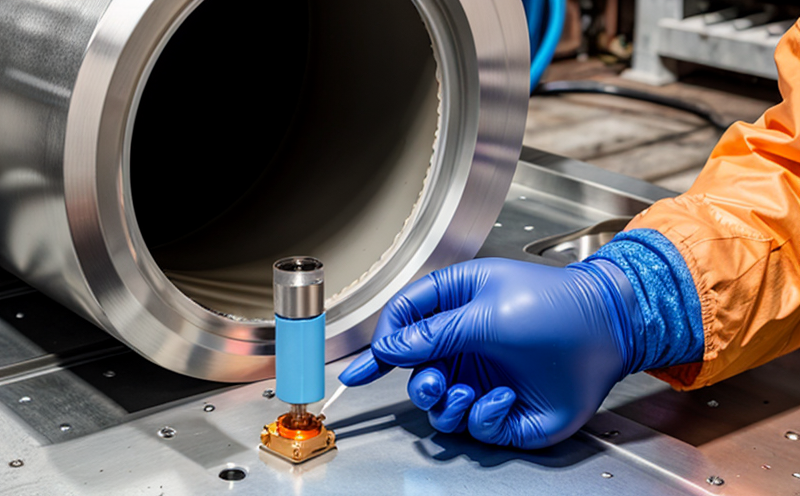

State-of-the-art facilities Our cutting-edge laboratory equipment and trained technicians ensure accurate, reliable results that give you peace of mind.

Cost-effective solutions By identifying potential issues early on, we can help you avoid costly rework or replacement, making our services a sound investment for your business.

Customized Solutions

Eurolab understands that each business has unique requirements and challenges. Our comprehensive UV resistance testing services are tailored to meet the specific needs of your coatings, ensuring accurate results that inform product development and manufacturing processes.

Expertise You Can Trust

At Eurolab, we pride ourselves on delivering exceptional results, backed by our teams collective experience in materials science and laboratory testing. We will work closely with you to develop a customized testing plan that addresses your specific concerns and goals.

QA Frequently Asked Questions about UV Resistance Testing for Coatings on Metals

What is UV resistance testing?

UV resistance testing measures the ability of coatings on metals to withstand exposure to ultraviolet radiation without degrading or losing their protective properties.

Why is UV resistance testing important?

Conducting UV resistance testing ensures that your coatings can perform optimally in various environmental conditions, preventing issues such as color change, adhesion loss, and material degradation.

What types of materials are tested for UV resistance?

Our laboratory services cover a wide range of coating types, including paints, varnishes, lacquers, epoxies, polyurethanes, and more. We also test coatings on various metal substrates, such as steel, aluminum, copper, and titanium.

What is the testing process like?

Our expert team will work closely with you to develop a customized testing protocol that caters to your specific needs. This may involve exposing the coated samples to controlled UV radiation in our state-of-the-art laboratory facilities.

How long does the testing process take?

The duration of the testing process varies depending on the specific requirements of each project. Our team will provide you with detailed timelines and progress updates throughout the testing process.

Can I request customized testing protocols?

Yes! At Eurolab, we understand that each business has unique needs and challenges. We will work closely with you to develop a tailored testing plan that addresses your specific concerns and goals.

Conclusion Empowering Your Business through UV Resistance Testing

UV resistance testing for coatings on metals is an essential tool in todays competitive market. By understanding the effects of UV radiation on your coatings, you can design and develop products that meet the demands of various environments, enhancing product quality, reducing costs, and improving efficiency.

At Eurolab, we are committed to providing innovative solutions that empower businesses like yours. Our comprehensive UV resistance testing services are tailored to cater to your specific needs, ensuring accurate results that inform product development and manufacturing processes.

Take the first step towards unlocking the secrets of UV resistance testing for coatings on metals. Contact us today to discuss how our laboratory services can benefit your business.

References

American Society for Testing and Materials (ASTM). (2019). Standard Test Method for Resistance of Paint Films to Ultraviolet Light (UV).

European Coatings Association (APE). (2020). Guidelines for the Selection and Application of Coatings.

International Organization for Standardization (ISO). (2017). ISO 4892-22017 - Plastics - Methods of exposure to laboratory light sources - Part 2 Xenon arc lamps.

By partnering with Eurolab, you can gain a deeper understanding of your coatings performance under real-world conditions, making informed decisions about product development and manufacturing processes.