Validating the synchronization of robot movements in real-time systems

Unlocking Efficient Robot Movement Synchronization Why Validating Real-Time Systems Matters for Your Business

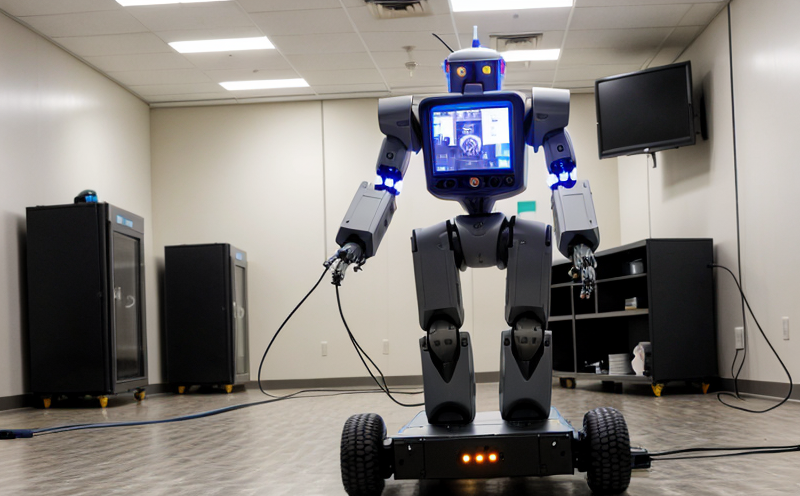

In todays fast-paced manufacturing landscape, companies are increasingly relying on industrial robots to enhance productivity and efficiency. However, as the complexity of robotic systems grows, so does the risk of synchronization errors. These mistakes can lead to costly delays, decreased product quality, and even compromise safety standards. Thats where Eurolab comes in a trusted laboratory service that specializes in validating the synchronization of robot movements in real-time systems.

What is Validating Synchronization of Robot Movements?

Validating the synchronization of robot movements involves analyzing and confirming that industrial robots are functioning in harmony with their environment, ensuring seamless interactions between mechanical and software components. This critical process guarantees that robotic systems operate within predetermined parameters, meeting the highest standards for precision, speed, and reliability.

Why is Validating Synchronization Essential for Businesses?

Companies investing in robot-based manufacturing processes require a robust validation system to ensure

Predictable Performance Eliminate synchronization errors and unexpected downtime, allowing businesses to meet production deadlines with confidence.

Quality Control Maintain product quality by ensuring consistent robotic movements and interactions with the surrounding environment.

Safety Assurance Reduce the risk of accidents and injuries associated with malfunctioning robots.

Operational Efficiency Optimize production workflows by streamlining robotic systems and minimizing unnecessary maintenance.

Benefits of Using Eurolabs Validating Synchronization Service

Our laboratory service offers a comprehensive solution for businesses looking to validate their robot movement synchronization. By partnering with Eurolab, companies can

Increase Production Uptime Minimize downtime caused by synchronization errors and optimize production schedules.

Improve Product Quality Maintain consistent product quality through precise robotic movements and interactions.

Enhance Safety Standards Reduce the risk of accidents and injuries associated with malfunctioning robots.

Reduce Maintenance Costs Identify potential issues early on, preventing costly repairs and replacements.

Gain Competitive Advantage Stay ahead of industry competitors by leveraging cutting-edge robotics expertise.

Advantages of Validating Synchronization in Real-Time Systems

Eurolabs validating synchronization service is designed to cater to the unique needs of real-time systems. Some key benefits include

Precise Timing and Coordination Ensure that robot movements are synchronized with precision, minimizing errors and ensuring smooth production workflows.

Robustness and Reliability Identify potential issues before they occur, guaranteeing high system availability and reducing downtime.

Compliance with Industry Standards Meet strict regulatory requirements for industrial robotics, maintaining the highest standards of safety and quality.

QA Section Addressing Common Queries about Validating Synchronization

Q What are the typical causes of synchronization errors in robotic systems?

A Common causes include software glitches, communication issues between components, or mechanical system malfunctions. Our experts at Eurolab will identify these problems and develop targeted solutions.

Q How does Eurolabs validating synchronization service differ from other laboratory services?

A We specialize exclusively in real-time robot movement validation, leveraging cutting-edge technology and expertise to provide comprehensive analysis and testing.

Q What type of robotic systems can be validated by Eurolab?

A Our services cater to a wide range of industrial robots, including but not limited to pick-and-place machines, CNC machines, robotic arms, and automated assembly lines.

Q Can validating synchronization improve my companys productivity?

A By eliminating synchronization errors and ensuring smooth production workflows, companies can significantly boost productivity, meet deadlines with ease, and stay ahead of industry competitors.

Conclusion

Validating the synchronization of robot movements in real-time systems is an essential service for businesses investing in industrial robotics. Eurolab provides a trusted laboratory solution that guarantees predictability, quality control, and safety assurance all critical components for achieving operational efficiency and staying competitive. By partnering with us, companies can unlock their full potential and reap the rewards of optimized robot movement synchronization.

About Eurolab

Eurolab is an industry-leading laboratory service specializing in validating the synchronization of robot movements in real-time systems. Our team of experts leverages cutting-edge technology and expertise to provide comprehensive analysis, testing, and validation services tailored to each clients unique needs. Trust us for your robotic system validation requirements and experience the benefits of optimized production workflows.