Verifying that contact resistance is minimized in high-frequency applications, such as RF or audio devices

Minimizing Contact Resistance in High-Frequency Applications Ensuring Reliability and Efficiency

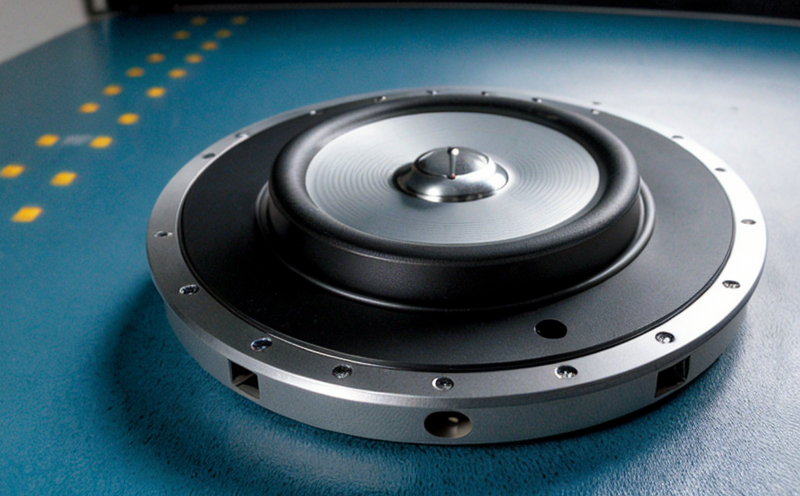

In the world of high-frequency applications, such as radio frequency (RF) or audio devices, even the slightest imperfection can have a significant impact on performance and functionality. One critical aspect that often goes unnoticed is contact resistance the opposition to current flow between two conductors when they come into contact with each other. Verifying that contact resistance is minimized in these applications is crucial for businesses seeking to maintain product reliability, efficiency, and overall quality.

The Importance of Minimizing Contact Resistance

In high-frequency applications, contact resistance can cause a range of issues, including

Signal degradation or distortion

Reduced system performance

Increased power consumption

Heat generation

These problems not only affect the devices functionality but also contribute to wasted resources and reduced lifespan. By minimizing contact resistance, manufacturers can ensure that their products operate at optimal levels, resulting in improved customer satisfaction, increased market share, and ultimately, greater profits.

Benefits of Verifying Contact Resistance

Eurolab offers a laboratory service designed specifically for high-frequency applications verifying that contact resistance is minimized. Our expert technicians utilize state-of-the-art equipment to analyze and measure contact resistance, providing accurate and reliable results. The benefits of this service include

Improved Product Performance By minimizing contact resistance, manufacturers can ensure their products operate at peak performance levels.

Reduced Power Consumption Lower contact resistance translates to reduced power consumption, resulting in energy savings and a lower environmental impact.

Increased Reliability Minimized contact resistance contributes to longer product lifespan and reduced maintenance needs.

Enhanced Customer Satisfaction Products that meet or exceed expectations lead to increased customer satisfaction and loyalty.

Competitive Advantage By prioritizing contact resistance verification, businesses can differentiate themselves from competitors and establish a reputation for quality.

How Eurolabs Contact Resistance Verification Service Works

Our laboratory service is designed to provide precise measurements of contact resistance in high-frequency applications. Heres how we do it

Sample Preparation We carefully prepare the samples according to the customers specifications.

Measurement Our expert technicians utilize state-of-the-art equipment, such as Agilent or Rohde Schwarz instruments, to measure contact resistance under controlled conditions.

Data Analysis We thoroughly analyze the measurement data to ensure accurate and reliable results.

Comprehensive Benefits of Eurolabs Service

Eurolabs contact resistance verification service offers numerous benefits for businesses involved in high-frequency applications

Accurate Measurements Our expert technicians provide precise measurements, ensuring that our customers receive accurate results.

Cost-Effective Solutions By identifying and minimizing contact resistance issues early on, manufacturers can avoid costly redesigns or rework.

Increased Productivity With our service, businesses can accelerate product development cycles, improving time-to-market and overall competitiveness.

Frequently Asked Questions (FAQs)

Q What is contact resistance?

A Contact resistance refers to the opposition to current flow between two conductors when they come into contact with each other.

Q Why is minimizing contact resistance important in high-frequency applications?

A Minimizing contact resistance ensures product performance, reliability, and efficiency in high-frequency applications.

Q What types of devices are affected by contact resistance?

A High-frequency applications such as RF or audio devices are susceptible to contact resistance issues.

Q How does Eurolabs laboratory service work?

A We prepare samples according to customer specifications, measure contact resistance using state-of-the-art equipment, and analyze data for accurate results.

Q What are the benefits of minimizing contact resistance in high-frequency applications?

A Benefits include improved product performance, reduced power consumption, increased reliability, enhanced customer satisfaction, and a competitive advantage.

Conclusion

Minimizing contact resistance in high-frequency applications is crucial for businesses seeking to maintain product reliability, efficiency, and overall quality. Eurolabs laboratory service offers accurate measurements, cost-effective solutions, and increased productivity, making it an essential tool for manufacturers involved in high-frequency applications. By choosing our contact resistance verification service, businesses can ensure their products meet or exceed expectations, resulting in improved customer satisfaction, increased market share, and ultimately, greater profits.

Why Choose Eurolab?

With years of experience and a reputation for excellence, Eurolab is the trusted partner for manufacturers seeking to optimize product performance and reliability. Our expert technicians, state-of-the-art equipment, and comprehensive services ensure accurate and reliable results. Contact us today to learn more about our contact resistance verification service and how we can help your business thrive in the competitive high-frequency applications market.