Verifying that the device’s mechanical housing can withstand prolonged exposure to vibration

The Crucial Role of Vibration Testing in Ensuring Device Reliability

In todays fast-paced business environment, companies are under immense pressure to deliver high-quality products that meet the ever-changing needs of their customers. One critical aspect of ensuring device reliability is verifying that a products mechanical housing can withstand prolonged exposure to vibration. This laboratory service, provided by Eurolab, is essential for businesses seeking to guarantee the longevity and performance of their devices.

The Importance of Vibration Testing

Vibration testing is a rigorous process designed to simulate real-world operating conditions, subjecting devices to various levels of mechanical stress. By exposing products to controlled vibrations, manufacturers can identify potential weaknesses in the devices mechanical housing, allowing for prompt corrective action to prevent costly failures and downtime.

In industries where equipment failure can have severe consequences, such as aerospace, automotive, or medical, vibration testing is a non-negotiable step in the product development process. A single malfunctioning device can lead to catastrophic outcomes, resulting in financial losses, damage to reputation, and even harm to peoples lives.

Advantages of Vibration Testing

Eurolabs vibration testing service offers numerous benefits to businesses seeking to ensure their devices meet the required standards

Enhanced Product Reliability By simulating real-world operating conditions, companies can identify potential weaknesses in their products, allowing for prompt corrective action to prevent costly failures and downtime.

Reduced Warranty Claims Vibration testing enables manufacturers to pinpoint areas of concern before shipping products, minimizing the likelihood of warranty claims and associated costs.

Improved Customer Satisfaction By ensuring devices withstand vibration stress, companies can maintain customer trust and loyalty, leading to increased brand reputation and market share.

Compliance with Industry Standards Eurolabs vibration testing service helps businesses meet regulatory requirements, reducing the risk of non-compliance fines and penalties.

Increased Product Lifespan By identifying and addressing mechanical weaknesses, manufacturers can extend product lifespan, reducing replacement costs and minimizing electronic waste.

Key Benefits of Eurolabs Vibration Testing Service

Eurolabs vibration testing service is designed to meet the specific needs of businesses in various industries. Some key benefits include

Customized Test Plans Eurolabs experienced team works closely with clients to develop tailored test plans, ensuring that products are subjected to relevant and realistic vibration stress.

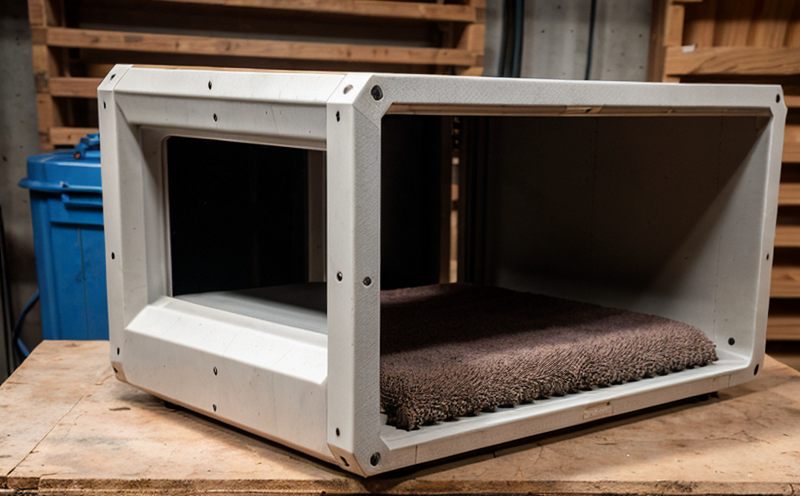

State-of-the-Art Equipment Our laboratory is equipped with the latest technology, enabling us to simulate a wide range of vibration profiles, from low-frequency vibrations to high-impact shocks.

Rapid Turnaround Times Eurolabs efficient testing procedures ensure that clients receive timely results, allowing for swift corrective action and minimizing production delays.

QA Frequently Asked Questions about Vibration Testing

Q1 What is the purpose of vibration testing?

A Vibration testing simulates real-world operating conditions to identify potential weaknesses in a devices mechanical housing. This helps manufacturers prevent costly failures and downtime.

Q2 Why is vibration testing essential for certain industries?

A Industries where equipment failure can have severe consequences, such as aerospace, automotive, or medical, require vibration testing to ensure devices meet the required standards.

Q3 How does Eurolabs vibration testing service benefit businesses?

A Our service enhances product reliability, reduces warranty claims, improves customer satisfaction, ensures compliance with industry standards, and increases product lifespan.

Q4 Can I customize the test plan for my products?

A Yes, our experienced team works closely with clients to develop tailored test plans that simulate relevant and realistic vibration stress for each product.

Conclusion

In todays competitive business landscape, companies must prioritize device reliability to maintain customer trust and loyalty. Eurolabs vibration testing service is a critical step in ensuring devices can withstand prolonged exposure to vibration, reducing the risk of costly failures and downtime. By choosing Eurolabs laboratory services, businesses can enhance product reliability, reduce warranty claims, improve customer satisfaction, ensure compliance with industry standards, and increase product lifespan.

Dont compromise on device reliability choose Eurolab for your vibration testing needs.