Verifying that the flexibility of materials like plastics and composites does not affect their overall strength

Unlocking the Secrets of Flexible Materials Why Verifying Their Strength Matters

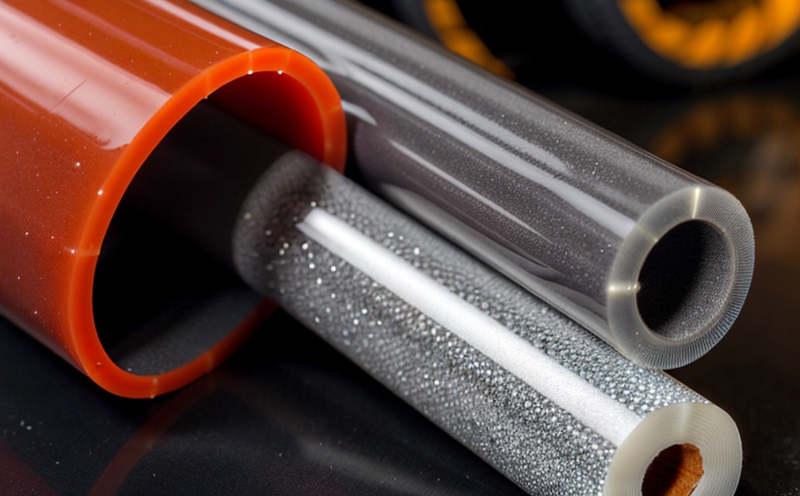

In todays fast-paced manufacturing landscape, businesses are constantly seeking innovative materials to stay ahead of the competition. Plastics and composites have become increasingly popular due to their versatility, durability, and cost-effectiveness. However, one crucial aspect often overlooked is the relationship between flexibility and strength in these materials. Thats where Verifying that the flexibility of materials like plastics and composites does not affect their overall strength comes into play a critical laboratory service provided by Eurolab.

As a leading provider of laboratory services, Eurolab understands the importance of ensuring that materials meet the required standards before they hit the production line. Our team of experts is dedicated to helping businesses like yours make informed decisions about material selection and development. In this article, well delve into the world of flexible materials, exploring why verifying their strength is essential for businesses and highlighting the benefits of our laboratory service.

What is Verifying that the flexibility of materials like plastics and composites does not affect their overall strength?

Verifying that the flexibility of materials like plastics and composites does not affect their overall strength involves conducting a series of tests to determine the materials resistance to deformation, fracture, or failure. This process helps manufacturers understand how their materials will behave under various conditions, such as temperature changes, impact loads, or chemical exposure.

In essence, its about ensuring that the flexibility of these materials doesnt compromise their structural integrity. By verifying the strength of flexible materials, businesses can

Reduce the risk of material failure

Optimize product design and performance

Enhance safety features and user experience

Meet regulatory requirements and industry standards

Advantages of Using Verifying that the flexibility of materials like plastics and composites does not affect their overall strength

Our laboratory service offers a range of benefits for businesses, including

Improved Material Selection

By verifying the strength of flexible materials, manufacturers can select the most suitable materials for their products, reducing the risk of material failure and optimizing performance.

Enhanced product reliability

Increased customer satisfaction

Reduced warranty claims

Increased Efficiency

Our laboratory service helps businesses streamline their development process by providing accurate and reliable data on material properties. This enables manufacturers to

Accelerate product design and testing cycles

Reduce material waste and costs

Enhance overall production efficiency

Compliance with Industry Standards

Verifying the strength of flexible materials ensures compliance with regulatory requirements and industry standards, protecting businesses from potential liabilities and reputational damage.

Reduced risk of non-compliance

Enhanced brand reputation

Improved customer trust

Informed Decision-Making

Our laboratory service provides businesses with the data they need to make informed decisions about material selection and development. This enables manufacturers to

Make data-driven decisions

Optimize product design and performance

Stay ahead of the competition

Frequently Asked Questions (FAQs)

Q What types of materials can be tested for flexibility and strength?

A Our laboratory service can test a wide range of flexible materials, including plastics, composites, elastomers, and polymers.

Q How do I prepare my samples for testing?

A Please follow our sample preparation guidelines to ensure accurate and reliable results. Contact us for more information.

Q What kind of data can I expect from the testing process?

A Our laboratory service provides comprehensive reports detailing material properties, including flexibility, strength, and deformation characteristics.

Q How long does the testing process take?

A The duration of our testing services varies depending on the type and complexity of the tests. Contact us for more information.

Conclusion

Verifying that the flexibility of materials like plastics and composites does not affect their overall strength is a critical aspect of material development and selection. Our laboratory service at Eurolab provides businesses with the data they need to make informed decisions about material choice and product design.

By partnering with us, manufacturers can

Reduce material failure risks

Optimize product performance and reliability

Enhance customer satisfaction and brand reputation

Dont compromise on quality trust Eurolabs expertise in Verifying that the flexibility of materials like plastics and composites does not affect their overall strength. Contact us today to learn more about our laboratory services and how we can help your business succeed.

-

Testing the ability of materials to withstand bending forces without breaking

-

Simulating the effects of bending and flexing on construction materials under load

-

Evaluating the resistance of materials to deformation and failure when subjected to flexural stress

-

Testing for the maximum bending load that materials like concrete, metal, and composites can withstand

-

Ensuring that structural elements, such as beams and slabs, maintain their integrity when subjected to bending forces

-

Simulating conditions in which materials will bend under load and testing for any cracks or fractures

-

Verifying the suitability of materials used for structural support in bending applications

-

Ensuring that materials used in walls, floors, and ceilings maintain their strength under bending stress

-

Testing how materials react when subjected to bending in different environmental conditions, such as heat or moisture

-

Simulating the bending behavior of materials used in high-stress applications like bridges and highways

-

Evaluating the performance of materials used for flooring and roofing under bending conditions

-

Testing the flexural strength of materials used for insulation and soundproofing in construction

-

Simulating scenarios where bending forces are applied repeatedly to determine long-term durability

-

Testing how the shape and design of a material influence its resistance to bending or flexural forces

-

Ensuring that materials in construction retain their structural properties under bending stress over time

-

Verifying the strength and reliability of materials used in lightweight and modular construction

-

Testing for the ability of materials to return to their original shape after being bent (elasticity)

-

Evaluating materials for flexibility without compromising structural integrity or safety

-

Testing for bending failure, including cracking, warping, or twisting, under excessive load

-

Ensuring that building materials can resist bending deformation caused by shifting or settling foundations

-

Simulating real-world bending conditions, such as bending from wind or seismic forces, to test material resilience

-

Testing for the ability of materials to support heavy loads without losing their shape or structural performance