Verifying the impact of sustained loads on robot joints and motors

Verifying the Impact of Sustained Loads on Robot Joints and Motors Essential Testing for Business Success

In todays fast-paced world of robotics and automation, ensuring that your equipment can withstand the demands of heavy use is crucial for businesses looking to maintain efficiency, productivity, and reliability. One critical aspect of this is verifying the impact of sustained loads on robot joints and motors a laboratory service provided by Eurolab that can make all the difference between smooth operation and costly downtime.

What is Verifying the Impact of Sustained Loads?

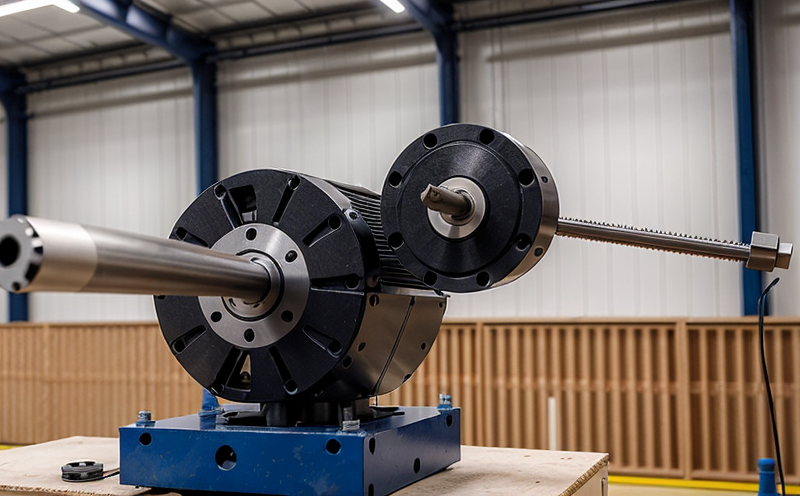

Verifying the impact of sustained loads on robot joints and motors involves subjecting these critical components to prolonged periods of load, simulating real-world usage patterns. This laboratory testing service aims to assess how well your equipment can handle repeated stress, strain, and wear, helping you identify potential issues before they arise.

Why is Verifying the Impact of Sustained Loads Essential for Businesses?

In a world where even minor equipment failures can lead to significant losses in productivity, revenue, and reputation, its more important than ever to ensure your robot joints and motors are up to the task. Here are just some of the reasons why verifying the impact of sustained loads is essential for businesses

Key Benefits of Verifying the Impact of Sustained Loads on Robot Joints and Motors

Reduced Downtime By identifying potential issues before they become major problems, you can minimize downtime and keep your equipment running smoothly.

Improved Reliability Eurolabs laboratory testing service helps ensure that your robot joints and motors are designed to withstand the stresses of heavy use, reducing the likelihood of unexpected failures.

Increased Efficiency With optimized equipment performance, you can achieve higher productivity rates and better overall efficiency.

Enhanced Safety By identifying potential hazards and weaknesses, you can take steps to mitigate risks and create a safer working environment for your team.

Cost Savings Preventing costly repairs and replacements by addressing issues early on can save your business significant amounts of money over time.

Additional Benefits

Compliance with Industry Standards Eurolabs laboratory testing service helps ensure that your equipment meets the latest industry standards, reducing the risk of non-compliance and related costs.

Competitive Advantage By investing in thorough testing and verification, you can gain a competitive edge in the market and differentiate yourself from rivals.

Common Applications for Verifying the Impact of Sustained Loads

Verifying the impact of sustained loads on robot joints and motors has numerous applications across various industries, including

Robotics and Automation

Industrial Manufacturing

Aerospace and Defense

Healthcare and Medical Devices

Automotive and Transportation

Frequently Asked Questions (FAQs)

Q What is the purpose of verifying the impact of sustained loads on robot joints and motors?

A The primary goal is to assess how well your equipment can handle repeated stress, strain, and wear, helping you identify potential issues before they arise.

Q Why is it essential to verify the impact of sustained loads in the robotics industry?

A In robotics, even minor equipment failures can lead to significant losses in productivity, revenue, and reputation. Verifying the impact of sustained loads helps ensure that your robot joints and motors are designed to withstand the stresses of heavy use.

Q What type of equipment is typically tested for verifying the impact of sustained loads?

A Eurolabs laboratory testing service covers a wide range of equipment, including robot joints and motors, as well as other critical components such as gears, bearings, and shafts.

Q How long does the verification process typically take?

A The duration of the verification process varies depending on the specific requirements of your project. Our team will work closely with you to develop a tailored testing plan that meets your needs.

Q What kind of results can I expect from Eurolabs laboratory testing service?

A Youll receive detailed reports outlining the performance of your equipment under sustained loads, including recommendations for improvement and optimization.

Conclusion

Verifying the impact of sustained loads on robot joints and motors is a critical aspect of ensuring business success in todays fast-paced world of robotics and automation. By investing in Eurolabs laboratory testing service, you can reduce downtime, improve reliability, increase efficiency, enhance safety, and achieve cost savings. Dont wait until its too late contact us today to learn more about how we can help your business thrive.

Additional Resources

Whitepaper The Importance of Verifying the Impact of Sustained Loads on Robot Joints and Motors(link)

Case Study Successful Implementation of Eurolabs Laboratory Testing Service in a Robotics Manufacturing Facility(link)