Vibration Durability Testing for Marine Sensors

Vibration Durability Testing for Marine Sensors Ensuring Reliability and Performance in Harsh Environments

As the global marine industry continues to grow and evolve, the demand for reliable and durable sensors has never been higher. Marine sensors play a critical role in ensuring the safe operation of vessels, monitoring environmental conditions, and optimizing performance. However, these sensors are often subjected to harsh environments, extreme temperatures, and intense vibrations that can compromise their reliability and accuracy.

This is where Vibration Durability Testing for Marine Sensors comes into play. Conducted by Eurolab, a leading laboratory service provider, this testing ensures that marine sensors can withstand the rigors of marine environments and perform consistently under varying conditions. In this article, we will delve into the importance of Vibration Durability Testing for Marine Sensors, its advantages, and how it can benefit businesses in the industry.

What is Vibration Durability Testing for Marine Sensors?

Vibration Durability Testing for Marine Sensors is a comprehensive laboratory testing service that simulates real-world marine environments to evaluate the performance and durability of sensors. This involves subjecting the sensors to intense vibrations, temperature fluctuations, and other environmental stresses to assess their reliability and accuracy.

During this testing process, sensors are exposed to various types of vibration profiles, including sinusoidal, random, and shock loading. The results are then analyzed to determine the sensors response to these conditions, identifying any potential weaknesses or vulnerabilities.

Why is Vibration Durability Testing for Marine Sensors Essential?

The marine industry is subject to some of the most challenging environmental conditions on earth. Sensors must be able to withstand

Extreme temperatures ranging from -40C to 120C

High salt concentrations and corrosive environments

Intense vibrations and shocks caused by waves, propellers, and other mechanical components

Exposure to water and moisture

Failing to test marine sensors for vibration durability can lead to costly consequences, including

Sensor failure and downtime

Reduced accuracy and reliability

Increased maintenance costs

Potential safety risks for crew members and passengers

Benefits of Vibration Durability Testing for Marine Sensors

The advantages of Vibration Durability Testing for Marine Sensors are numerous. Some of the key benefits include

Improved Sensor Reliability By simulating real-world marine environments, Eurolabs testing ensures that sensors can withstand the stresses and strains they will face in actual operation.

Enhanced Accuracy Tested sensors perform consistently under varying conditions, reducing errors and improving overall system performance.

Reduced Maintenance Costs Sensors that have been tested for vibration durability require less maintenance, as any potential weaknesses or vulnerabilities are identified early on.

Increased Safety By ensuring sensor reliability and accuracy, the risk of accidents and injuries is significantly reduced.

Compliance with Industry Standards Eurolabs testing meets and exceeds industry standards, including those set by major classification societies such as DNV GL and ABS.

Competitive Advantage Businesses that invest in Vibration Durability Testing for Marine Sensors gain a competitive edge in the market, as they can offer more reliable and durable products to their customers.

How Does Eurolabs Vibration Durability Testing Service Work?

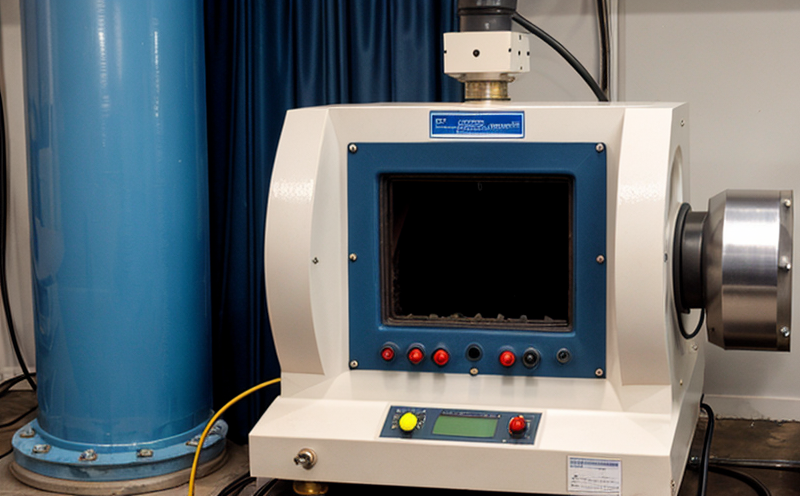

Eurolabs state-of-the-art laboratory facilities are equipped with advanced testing equipment and instrumentation, enabling our expert technicians to simulate real-world marine environments. The testing process typically involves the following steps

Sensor Preparation Sensors are thoroughly cleaned and prepared for testing.

Vibration Profile Development Eurolab develops customized vibration profiles that simulate real-world marine conditions.

Testing Sensors are subjected to the developed vibration profile, with results recorded and analyzed in real-time.

Data Analysis Results are meticulously analyzed to determine sensor performance and identify any potential weaknesses or vulnerabilities.

Frequently Asked Questions (FAQs)

Q What types of sensors can be tested for Vibration Durability?

A Eurolabs testing service is applicable to a wide range of marine sensors, including pressure, temperature, flow rate, and level sensors.

Q How long does the testing process typically take?

A The duration of the testing process varies depending on the type and complexity of the test. However, most tests can be completed within 1-5 days.

Q What are the benefits of testing my marine sensors with Eurolab?

A By partnering with Eurolab for Vibration Durability Testing, you gain access to expert technicians, state-of-the-art equipment, and a comprehensive testing service that meets and exceeds industry standards.

Q Can I see a sample test report from Eurolabs laboratory?

A Yes, we would be happy to provide a sample test report upon request. Our reports are detailed, easy to understand, and provide actionable insights for your business.

Conclusion

Vibration Durability Testing for Marine Sensors is an essential service that ensures the reliability and performance of critical sensors in harsh marine environments. By investing in Eurolabs comprehensive laboratory testing service, businesses can

Reduce sensor failure and downtime

Improve accuracy and reliability

Minimize maintenance costs

Increase safety for crew members and passengers

Gain a competitive edge in the market

Contact us today to learn more about how Vibration Durability Testing for Marine Sensors from Eurolab can benefit your business.